Electric valves have the advantages of easy assembly and low failure rate, becoming the mainstream of the market

Electric valves have the advantages of easy assembly and low failure rate, becoming the mainstream of the market

In terms of operating efficiency and saving energy consumption, the use of automatic control valves is an indispensable part. The manual valves and pneumatic valves commonly used in traditional industries are not as good as electric valves in terms of installation cost and efficiency.

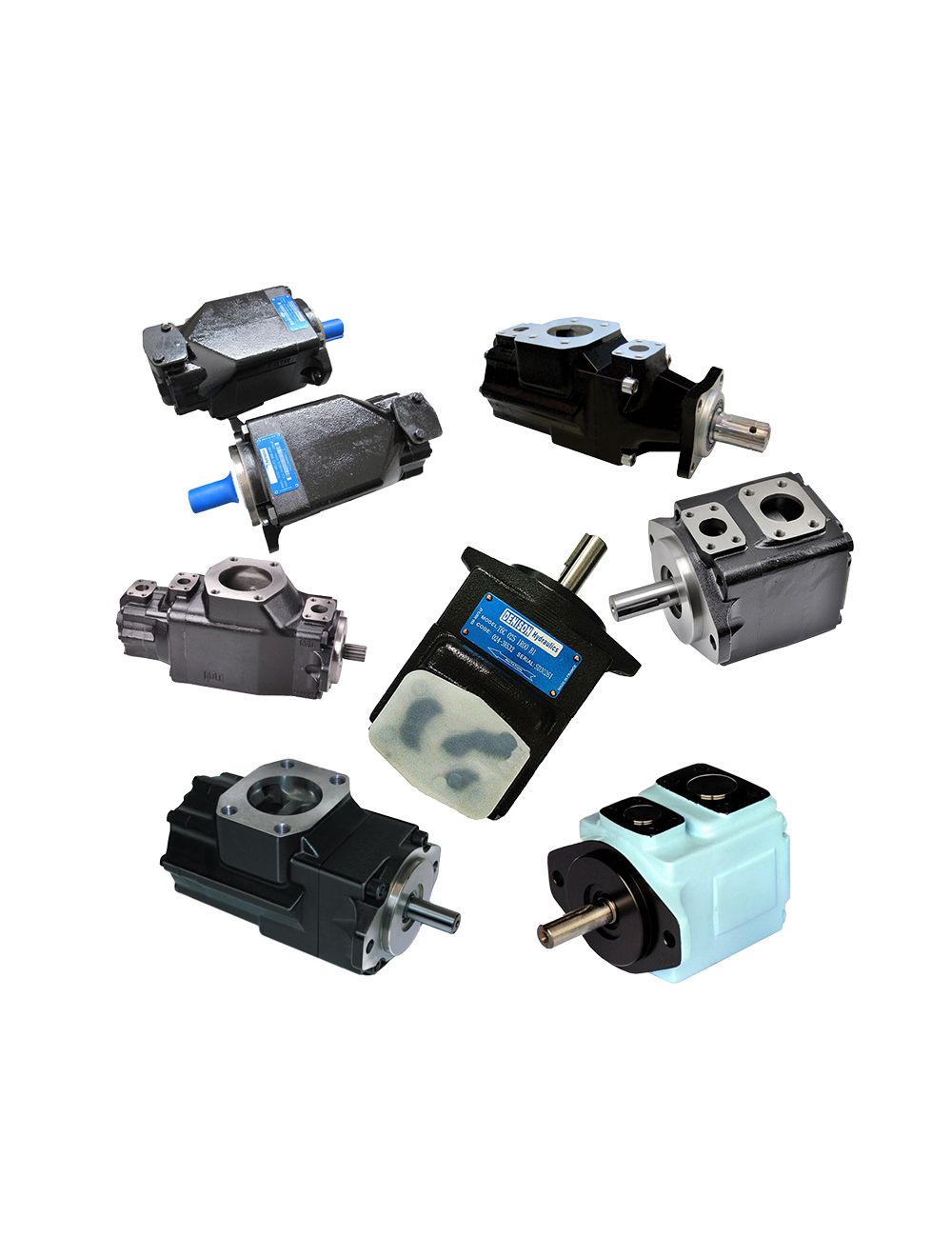

As far as the product itself is concerned, because the electric valve has the advantages of easy assembly, low failure rate and meeting the industry's automation needs, it is a more cost-effective choice for the industry. Because the general traditional pneumatic valve is used, it is inevitable to have piping, solenoid valve and compressor to match, and the electric valve is driven by a motor, which is easy to install and hassle-free, and the electric valve can be installed with the factory's original automatic control circuit, which can save other the costing payment. In addition, the opening and closing of the motor drive is smoother, without the shortcomings of excessive momentary force, and the failure rate can be greatly reduced.

Relevant persons in the industry said that valves are mostly used in industrial processes to control the travel and flow of various fluids, such as water, oil, chemical liquids, etc., based on parameters such as temperature, pressure and flow. The control valves commonly used in factories include pressure reducing valves, pneumatic constant temperature valves, solenoid valve constant temperature systems, proportional control valve constant temperature systems, and temperature control valves. When selecting various types of automatic valves, consideration should be given to factors such as the type of heat engine, the required accuracy, the quality of the control valve, the pressure drop, the flow rate and its structure, the failure rate, the credit of the manufacturer, and the after-sales service to achieve economical and practical purposes.

Many people think that electric valves are expensive and costly to use. In fact, it is not. If calculated as a whole, traditional valves have to be installed with many accessories and pipelines. The price is not dominant, but more maintenance costs.

Recent related posts

09/11/2020

Electric valves have the advantages of easy assembly and low failure rate, becoming the mainstream of the market

In terms of operating efficiency and saving energy consumption, the use of automatic control valves is an indispensable part. The manual valves and pneumatic valves commonly used in traditional industries are not as good as electric valves in terms of installation cost and efficiency.

09/11/2020

Discussion on the Key Technology of DC Inverter Air Conditioner Control

Inverter air conditioners have become a hot spot for the development of air-conditioning companies because of their energy-saving, comfortable, and high-energy-efficiency advantages and conform to the national policy of "energy saving and emission reduction".

09/11/2020

Development and Trend of my country's Frequency Converter Industry

With the rapid development of power electronics technology, computer technology and automatic control technology, electric drive technology is facing a historic revolution. AC drives have gradually become the mainstream of electric drives.

09/11/2020

Composition and maintenance of oil return check valve for Okmarts.com air compressor

The composition of okmarts.com air compressor check valve: the check valve is composed of valve body, steel ball, steel ball seat, spring and other elements

09/11/2020

Comparison of ball bearings and roller bearings

Comparison of ball bearings and roller bearings From the point of view of the contact with the raceway: Ball bearings are in point contact, and the contact surface is ellipsoid; while roller bearings are in line contact, and when force is applied, the contact surface is square.

09/11/2020

Chinese air-conditioning anchored new coordinates for industrial upgrading

Haier "zero distance" customization accelerates the restructuring of the air-conditioning industry The implementation of the new energy efficiency standards is imminent, and the air-conditioning industry may usher in a new inflection point.

09/11/2020

Bearings are classified according to whether they can be adjusted

Bearings can be divided into: 1. Self-aligning bearing: The raceway is spherical and can adapt to the angular deviation and angular movement between the axis of the two raceways. 2. Non-aligning bearings (rigid bearings): bearings that can resist the angular deviation of the axis between the raceways.

09/11/2020

Bearing and shaft fit tolerance standard

Bearing and shaft fit tolerance standard ①When the bearing inner diameter tolerance zone and the shaft tolerance zone form a fit, the tolerance code originally belonging to the transition fit in the general basic hole system will become an over-win fit, such as k5, k6, m5, m6, n6, etc., but the over-win amount is not Large; when the bearing inner diameter tolerance is matched with h5, h6, g5, g6, etc., it is not a clearance but an over-win fit.

09/11/2020

Bearing according to the type of rolling element

Bearings are classified according to the types of rolling elements: 1. Ball bearing: the rolling elements are balls 2. Roller bearing: the rolling element is roller

09/11/2020

Bearing according to the number of rows of rolling elements

According to the number of rows of rolling elements, bearings are divided into:<br></br> 1. Single row bearing: bearing with one row of rolling elements;<br></br> 2. Double row bearings: bearings with two rows of rolling elements;<br></br> 3. Multi-row bearings: bearings with more than two rows of rolling elements and bearing loads in the same direction.<br></br>

Customers frequently viewed

IWAYA DENKI Water Pump 25CJT0752

Panasonic Servo Motor MHMF022L1V2M

Honeywell Solenoid Valve VE4025B1045

ROTEN Mechanical Seal 8E5K-22-X

COOPER Transformer TP1-470-R

Bristol Compressor H21J253DBV

Omega Flowmeter FL-3840C

JK Magnet Pump JMH-453