According to the rated speed, hydraulic motors are divided into: high-speed hydraulic motors (rated speed higher than 500r/min), including gear, vane and axial piston types, and low-speed hydraulic motors (rated speed lower than 500r/min), including radial piston type.

According to their structure type, they can be divided into: gear type, vane type, piston type and other forms.

Figure 1: Working principle diagram of external hydraulic gear motor.

2.Are Hydraulic Motors Reversible?

Generally all hydraulic motors can rotate forward and reverse unless a counterbalance valve is attached to them.

3.Can a Hydraulic Pump be Used as a Motor?

In theory, the hydraulic pump and the hydraulic motor are reversible, that is, the hydraulic pump can also be used as a hydraulic motor. However, due to the different structures of various pumps, if you want to use a hydraulic pump as a motor, some improvements in the structure of some pumps are required.

The gear pump can be used as a hydraulic motor without any improvement. One important thing to note is that the size of the oil inlet and outlet should be the same. As long as the pressure oil is passed into the oil inlet, the force of the pressure oil acting on the involute tooth profile of the gear will generate a torque, making the gear shaft rotate.

The vane pump works because the vanes are close to the inner curve of the stator under the action of centrifugal force to form a sealed working chamber. Therefore, when using a vane pump as a hydraulic motor, measures such as adding springs at the root of the vanes should be taken. Otherwise, at the beginning, the pump is in a static state, and the working chamber cannot be formed without centrifugal force, and the motor cannot work.

When a piston pump used as a piston motor, the structure can be simplified, especially the axial piston pump. In terms of structure, the slipper structure can be simplified.

Figure 2: Swashplate axial piston pump structure diagram.

1-Swashplate; 2-Slipper; 3-Pressure plate; 4-Sleeve; 5-Piston; 6-Spring; 7-Cylinder block; 8-Linkage; 9-Transmission shaft; 10-Oil distribution disc; 11- Discharge port; 12-Suction port

4.Is a Hydraulic Motor the Same as a Pump? (Hydraulic Motor vs Hydraulic Pump)

They are different, specifically in the following aspects:

The pump is the energy device (power element), and the motor is the actuating element.

The pump generally rotates in one direction, while the motor can rotate forward and backward.

The suction chamber of the pump is generally vacuum, and the size of the inlet is usually larger than that of the outlet; the pressure of the oil discharge chamber of the motor is slightly higher than the atmospheric pressure, and the size of the inlet and outlet of the motor is the same.

The structure of the pump needs to ensure the self-priming ability, but the motor does not have this requirement

The pump needs high volumetric efficiency, while the motor needs high mechanical efficiency.

The pump is running continuously, and the oil temperature change is relatively small, while the motor often idles or stops, subject to frequent temperature shocks.

The starting of the pump relies on external mechanical power. The starting of the motor needs to overcome a large static friction, so it requires a large starting torque, small torque pulsation, and small internal friction.

5.What is the Difference between Hydraulic Motor and Electric Motor?

The main difference between a hydraulic motor and an electric motor is that the power source is different. The energy source of the hydraulic motor is the pressure potential energy of the hydraulic oil, and the energy source of the electric motor is the electric potential energy.

The hydraulic motor can not only rotate forward, but also can be freely changed among reverse rotation, variable speed, acceleration, etc., and it is easy to realize stepless speed regulation.

In general, the speed ratio of the hydraulic motor can be as high as 200, while that of the electric motor is lower than 50. Because the hydraulic motor has a wide range of speed ratios, it is of great significance to improve the working performance and production efficiency of the machine.

In addition, since the output torque of the hydraulic motor is proportional to the oil pressure, when high pressure is used in the system, a higher output torque can be obtained without excessively increasing its mass and volume.

Compared with the electric motor, the inertia of the rotating part of the hydraulic motor is small, and the start-up is fast and sensitive. Therefore, it is suitable for high-precision automatic control systems.

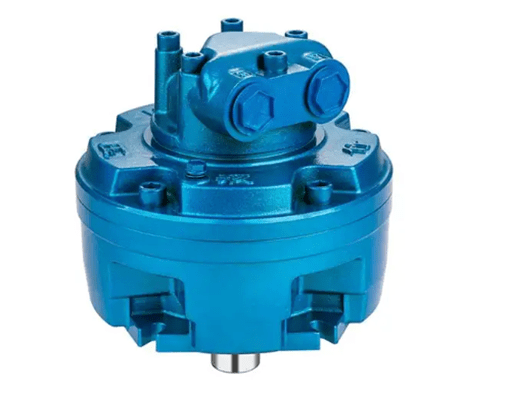

Figure 3: Radial piston hydraulic motor.

Because the viscosity of the oil can affect the characteristics of the hydraulic motor, it should not be used in places with severe temperature changes.

Hydraulic motors are very sensitive to oil contamination. Therefore, the working oil should be strictly filtered before use, which should be paid special attention to in maintenance.

6.Why is Hydraulics More Efficient than Electricity?

Compared with electric motors, hydraulic motors have some advantages over electric motors:

1. The drive shaft can be reversed instantly;

2. No matter how long the rotor is blocked, it will not cause damage;

3. The torque is controlled by the working speed, which is easy to realize dynamic braking;

4.Light weight and small size. When transmitting the same power, the mass of the hydraulic transmission device is 1/8~1/10 of the electric transmission, and the volume is 1/6~1/8.

5. Small inertia and fast response.

6. Compared with electric motors, hydraulic motors can obtain much lower stable working speeds.

7. Hydraulic transmission is safer than electric transmission in an explosive environment.

8. Hydraulic motor has better anti-moisture ability than electric motor.

7.Can Motor Oil be Used as Hydraulic Fluid?

Figure 4: Hydraulic oil.

Motor oil ( engine oil, machine oil) can not be used as hydraulic oil. Motor oil is usually used for engine lubrication systems, mainly for heat dissipation and lubrication, to prevent auto parts from overheating, while hydraulic oil is mainly used for torque transmission of hydraulic systems.

1.Motor oil can not replace hydraulic oil. If motor oil is added to the hydraulic system, although it can temporarily have the same effect as hydraulic oil, it will not take long for the oil seal and rubber seal in the hydraulic system to age quickly. Therefore, you can not use motor oil instead of hydraulic oil.

2. Hydraulic oil is formed by adding various additives to petroleum base oil, and has the same lubricity as engine oil while its anti-foaming and anti-emulsification properties are higher than those of engine oil.

3. A notable feature of hydraulic oil is high pressure resistance.

4. Hydraulic oil transmits pressure to do work, and its viscosity is relatively high, while motor oil is mainly lubricating oil with low viscosity, and the viscosity will continue to decrease as the temperature rises, at least significantly lower than the hydraulic oil viscosity. Therefore, in theory, it is impossible to replace hydraulic oil with engine oil, which will reduce the power of the machine and cause oil leakage of the original parts.

8.What is a Hydraulic Motor Used for?

Hydraulic motors act as walking drives, steering drives, etc. in many mobile equipment, such as excavators, road rollers/compactors, asphalt pavers, skid steers, articulated loaders, tractors, agricultural spreaders, special harvesters (soybeans, fruits, peanuts), lawn mowers, rock drills, drilling rigs, forklifts, dump trucks, etc.

|

Hydraulic motor type |

Applicable working conditions |

Scope of application |

|

Hydraulic gear motor |

Simple structure, easy to manufacture, but large speed pulsation, motor load torque not large, speed stability requirements not high, noise limit not strict, suitable for high speed and low torque situation |

Drilling machine, ventilation equipment, etc. |

|

Orbital motor |

Medium load speed, small volume requirements |

Plastic machinery, coal mining machinery, excavators, etc. |

|

Vane motor |

Compact structure, small size, smooth motion, low noise, low load torque |

Grinding machine rotary table, machine tool control mechanism, etc. |

|

Axial piston motor |

Compact structure, small radial dimension, small rotational inertia, high speed, large load, variable speed requirement, small load torque, high smoothness requirement at low speed |

Cranes, winches, forklifts, internal combustion forklifts, CNC machine tools, mobile machinery, etc. |

|

Crankshaft connecting rod radial piston motor |

Large load torque, medium speed, large radial size |

Rubber and plastic machinery, walking machinery, etc. |

|

Inner Curve Radial Piston Motor |

Large load torque, low speed and high stability |

Excavators, tractors, cranes, shearers, etc. |

Table 1: Working conditions and application scope of various hydraulic motors.

If you have any questions about hydraulic motors, please feel free to leave a message for consultation! Okmarts is able to provide various brands of hydraulic pumps and motors, such as Char Lynn hydraulic motor, Eaton hydraulic motor, Parker hydraulic motor, Danfoss hydraulic motor, etc. If you have any interest, please contact us.

Related Info

How to Choose a Contactor?How to Maintain Circuit Breaker?

Choose the Right Circuit Breaker

Differences between Circuit Breaker and Isolator Switch

How Does a Hydraulic Drive Motor Work?