For refrigeration products, high efficiency and energy saving are the constant pursuit and breakthrough of technology. In cooling industry, Mitsubishi Electric has been occupying a significant place.

With article, we are going to talk about five advantages of refrigeration compressor of Mitsubishi Electric to allow everyone to understand the technologies of Mitsubishi, and how they have made Mitsubishi a big shot in HVAC industry worldwide.

Figure 1: Mitsubishi Electric air conditioner is applied for home use.

1. Scroll Compressor with Low-Pressure Chamber

The refrigeration compressor determines the comfort, energy-saving, noise, and service life of a central air conditioner. Mitsubishi Electric is a brand that has mastered the technology of double rotors, high-pressure chamber scroll compressors, and low-pressure chamber scroll compressors at the same time.

The structure with a low-pressure chamber is specially designed and developed for a large-capacity upper air outlet unit, and the linear frequency conversion takes into account energy-saving and stability.

In the process of the operation of compressors, as the increase of motor speed, the refrigerant flow is up. There may be a small number of liquid components in the inhaled refrigerant. The capacity of the compressor should be limited to 10HP. If the capacity exceeds 10HP, you need to use multiple compressors.

Figure 2: The low-pressure chamber scroll compressor is composed of rotor, axis, stator, oil pump, pipes, and scroll plates.

The low-pressure chamber scroll compressor adopts the structure of side suction and top discharge.

The inhaled refrigerant passes through the lower part of the chamber for "buffer" before being compressed. The gas refrigerant is sucked into the scroll and compressed directly. Few liquid refrigerants enter the motor under the action of gravity. After cooling the motor, it evaporates into a gas and then enters the scroll for compression.

The unique intake and exhaust structure can ensure the good stability of the compressor in response to the large capacity demand, and the maximum single capacity can reach 20HP. There is only one compressor in a single module, which can complete the linear regulation without starting and stopping when the air conditioning load changes from 0% to 100%.

Compared with the model with multiple compressors, the low-pressure chamber scroll type can guarantee Maximum Circuit Amps (MCA) and avoid the failure of lubricating oil balance circuits between compressors.

2. Optimized Scroll Structure

The optimized scroll structure of Mitsubishi compressors helps reduce the compression leakage and improve the compression efficiency.

The improved compressors of Mitsubishi are made of high-strength cast iron and special aluminum alloy. Therefore, the improvement reduces the leakage loss caused by material deformation during high-speed operation and maintains compression efficiency.

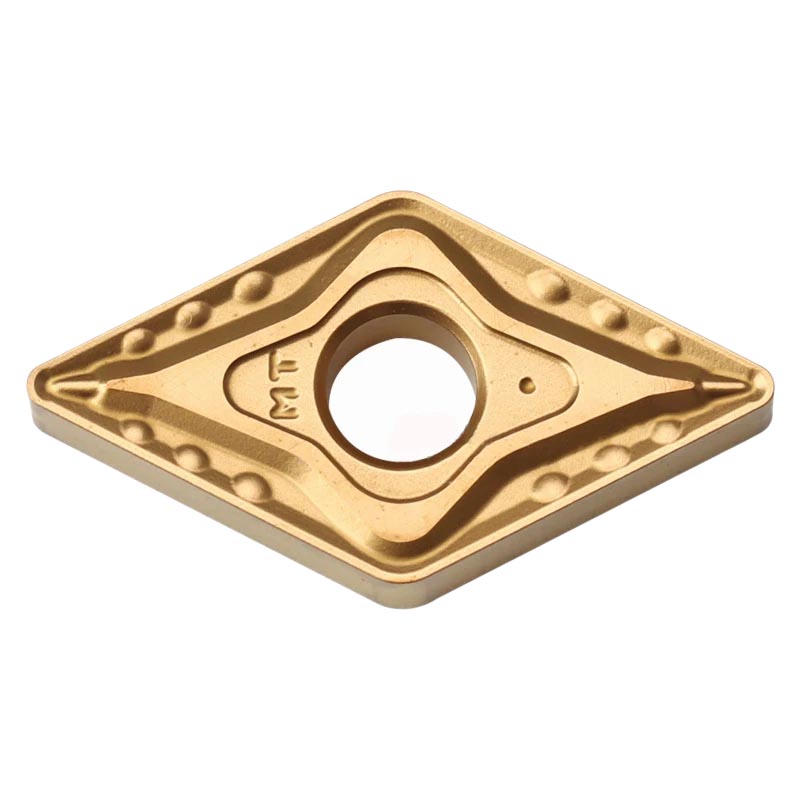

Figure 3: Mitsubishi Compressor ADB33FCAMTS

3. Higher Motor Torque

The rotor of Mitsubishi compressor is made of rare earth extracted from NdFeB material with the best flux characteristics, which can maximize the motor torque with the same power supply.

The embedded permanent magnetic frequency converter compressor superimposes the reluctance torque on the permanent magnet torque. The reluctance torque helps to improve the overload capacity and power density of the motor.

As one of the most powerful rare earth magnets, NdFeB has some superb features as below.

Good thermal stability of motor.

Small volume.

High torque works for higher efficiency.

4. Mitsubishi Patented Technology - DC Brushless Keel Cooling Motor

Due to the limitation of integrated core and winding technology, the distributed motor winding used in traditional compressor has a large gap between teeth and high copper and iron losses.

For the compressors of Mitsubishi high end multi connected central air conditioner (heat pump) units, City Multi series, Mitsubishi creatively introduces the unique patented technology "keel cooling motor", which uses the joint connection winding manufacturing process, and the winding is divided into sections and then closed assembled.

This technology reduces the dead zone area of the winding between gears to the minimum, makes effective use of all the winding, reduces the copper loss and iron loss of the motor, and improves the efficiency of the motor.

Figure 4: Keel cooling motor for the Mitsubishi compressor of City Multi series central air conditioner.

5. Silicon Carbide for Energy Efficiency

Mitsubishi Electric’s semiconductor products cover home appliances and are used in industrial and new energy applications, railway and power applications, as well as recently popular electric vehicle applications.

We may be most familiar with the frequency conversion air conditioner of Mitsubishi Electric. The application of semiconductor devices makes the frequency conversion air conditioner more energy-saving than the constant frequency air conditioner. It is of higher temperature control accuracy and faster temperature regulation speed so that we can live a comfortable life and save electricity that is contributed to environmental protection.

In modern society, a new generation of mobile communication, high-speed rail, smart grid, solar power generation by photovoltaic technology, electric vehicles, visible light storage, and communication are profoundly changing our lifestyle and production. And the semiconductor is a key technology to promote the development of these strategic industries.

With the development of silicon semiconductors for decades, the performance improvement is becoming smaller, which can not meet the development demand of low energy consumption, high efficiency, and miniaturization electronic products.

Silicon carbide, as a typical semiconductor material, has a very strong performance over silicon devices.

It can meet the new requirements of modern electronic technology for severe conditions such as high temperature, high power, high voltage, and high frequency.

It can significantly reduce the energy loss caused by various power conversions of electronic equipment and greatly reduce the volume of equipment.

Figure 5: Silicon carbide material

Till now, silicon carbide has been very important for industrial development. As the core materials and electronic components supporting the innovation, development, transformation, and upgrading of strategic industries, silicon carbide breaks through the technical limitations and is of milestone significance to the development of human science and technology.

Mitsubishi Electric has successfully developed a new generation of power devices based on silicon carbide chips and has established the manufacturing technology that can make full use of silicon carbide power semiconductors.

Find Quality Mitsubishi Compressor on OKmarts