Figure 1: The appearance of the crankshaft position sensor.

The crankshaft position sensor (CKPS) is a magnetic induction sensor with 58 slots on the crankshaft, each 6° apart. Among them, the last slot is wider and used to generate the synchronization pulse. As the crankshaft rotates, slots in the variable reluctance rotor change the sensor's magnetic field, forming an induced voltage pulse that identifies the direction of crankshaft rotation.

The crankshaft position sensor generates 58 reference pulse signals for each revolution of the crankshaft. The engine control unit calculates engine speed and measures crankshaft position according to these reference signals, which are important for the engine control unit to control ignition time.

If the crankshaft position sensor is broken, you can not confirm the rotation angle of the crankshaft, and the engine computer fails to receive the signal of the CKPS.

Crankshaft Position Sensor Troubleshooting

Visual Inspection

You should check whether the installation status of the sensor meets the requirements. In other words, the standard clearance between the sensor and the signal wheel is generally 0.8mm -1mm.

You should remove the sensor to inspect whether the permanent magnet is adsorbed with iron filings.

External Circuit Inspection

You can use the multimeter to measure the resistance value between the two terminals of the sensor and the corresponding terminals of the ECU respectively to determine whether there is a short circuit and circuit break fault of the external circuit.

Sensor Resistance Measurement

You should turn off the ignition switch, unplug the crankshaft position sensor, and measure the resistance value between terminals 1 # and 2 # , which varies greatly from model to model.

Waveform Measurement

The crankshaft position sensor output waveform can be measured with a fault detector. It is a very practical method because of the rich information contained in a waveform.

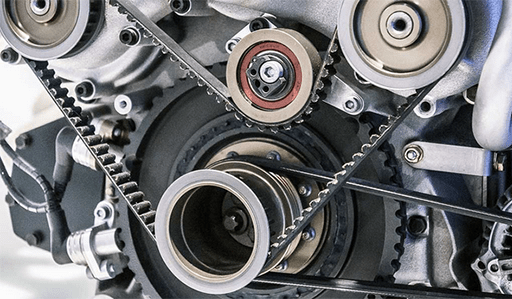

Figure 2: An engine crankshaft position sensor.

How to Test Crankshaft Position Sensors

The crankshaft position sensor is important in the injection and ignition system. The engine control unit receives crankshaft position and engine speed through the CKPS, so it can control the fuel injection, calculation of each cycle fuel injection quantity and when the lock work.

In some cases, before the engine receives the pulse signal from the crankshaft position sensor, it will not provide electricity to the ignition coil. The followings are detection methods of several types of crankshaft position sensors.

Magnetic Pulse CKPS Detection

* CKPS Resistance

You should pull out the wire connector and use a multimeter to measure the resistance between the terminals on the sensor. otherwise,, the sensor should be replaced.

* CKPS Output Signal

You should unplug the lead of the sensor and there should be pulse output between the G1-, G2- and G- terminals when running the engine. If there is no pulse signal output, please replace the sensor.

* Clearance between CKPS Coil and Rotor

You should check the air clearance between the signal rotor and the sensor coil bulge with a thickness gauge of 0.2 mm to 0.4mm. If the clearance does not meet the requirements, you need to adjust or replace it.

Figure 3: The structure of the crankshaft position sensor.

Detection of Photoelectric CKPS

The photoelectric crankshaft position sensor has two groups of photoelectric signal generators, which are centrally installed in the distributor.

When you are testing, you should unplug the sensor and switch on the ignition. The supply voltage should be 12 V. Or you can connect the ammeter between terminals 1 and 3, 1 and 4 on the 12 V battery voltage between sensor terminal 2 and terminal 1.

When the signal plate walks for a circle, the ammeter should swing 1 or 4 times, each time indicating 1 mA. And the voltage of different models should meet the corresponding provisions, otherwise, the photoelectric sensor should be replaced.

Detection of Hall Effect CKPS

Figure 4: The Hall Effect Crankshaft Position Sensor.

* Crankshaft Position and Angle Sensor

You should use the multimeter DCV to measure the supply voltage of the crankshaft position and angle sensor, which should be 12 V. Besides, you should measure the output signal voltage of the sensor in the starting state by the multimeter. The crankshaft position signal voltage should be 0.8-0.9V and the crankshaft angle signal voltage should be 2-3 V.

* Output Voltage of Hall Effect Sensor

You should turn off the ignition switch, open the distributor cover, pull out the central high voltage cable on the cover and attach the iron. After that, you should remove the rubber sleeve from the igniter connection plug, but keep the connection plug plugged.

You should connect the voltmeter pens to terminals 3 and 6, turn on the ignition switch, and finally turn the engine in the direction of engine rotation. You observe the voltmeter reading, which should change between 0-7V, and the crankshaft turns two times, the voltage changes 4 times, otherwise, it indicates that the Hall signal generator is faulty.

* Simulate Hall Effect Signal Generator

You should turn off the ignition switch, open the distributor cover, and turn the crankshaft so that the distributor triggers the impeller out of the air gap. You should remove the central high voltage wire from the electrical cover so that the end is 5mm to 7mm away from the cylinder block.

You then switch on the ignition and gently insert and pull out the screw in the signal generator's air gap, simulating the action of triggering the impeller in the air gap. If the high voltage line end is of fire, it will indicate that the signal generator is perfect. If not, it indicates that the signal generator is faulty and you should replace it.