In the next two years, the world's bearing demand will reach 76 billion US dollars

In the next two years, the world's bearing demand will reach 76 billion US dollars

According to the forecast analysis report of the global bearing market by the industry research company, the global demand for ball bearings, roller bearings and sliding bearings is expected to grow at an annual rate of 8.5%, reaching 76 billion US dollars by 2014, of which unloading The largest demand for ball bearings and roller bearings.

In 2011, unseat bearings will have the largest increase, which is mainly due to the increase in motor vehicle and industrial machinery production, as well as OEM and aftermarket demand. The growth rate of demand for plain bearings without seats and bearings with seats will also exceed the average. The demand for ordinary bearings will benefit from the growth in output of its main markets-motor vehicles and industrial machinery. The design of ordinary bearings has been continuously improved, and its price is lower than that of rolling element bearings, so sales can be increased. The sales of seated bearings are also growing, driven by industrial production (especially the construction, mining and oilfield markets).

Due to the continuous economic growth and the increase in fixed asset investment in many developed countries around the world, a new growth trend will appear in the bearing market. In addition, with the gradual receding of the economic crisis in 2009 and the rebound of the economies of all countries in the world, manufacturing and motor vehicle production have both increased compared with the data from 2004 to 2009 (the decline in global motor vehicle production from 2004 to 2009). However, the price of bearings will not increase by a large margin as during the period from 2004 to 2009, but will remain stable. This is mainly due to the fact that the prices of raw materials have become more reasonable, as well as the increasing international competition pressure brought by manufacturers in developing regions, which have stabilized the price increase to a certain extent.

The Asia-Pacific region has the strongest growth momentum

The report pointed out that the growth of bearing demand in the Asia-Pacific region will be the strongest, and China's bearing demand will rank first with an annual growth rate of 12.0%. The growth of China's bearing demand has benefited from the continuous advancement of its industrialization and the continuous growth of manufacturing. As of 2009, China has become the world's largest motor vehicle manufacturing country, which undoubtedly creates an excellent opportunity for bearing manufacturers to increase sales. The report predicts that by 2014, China's bearing demand will account for nearly 50% of global demand, and will exceed the total of the three major demand countries in North America, Western Europe and Japan in 2019.

From the perspective of past development, the growth of bearing demand in developed regions such as the United States, Western Europe, and Japan has slowed down compared with developing countries; but before 2014, this situation did not appear in all developed regions of the world. Because durable goods manufacturing (especially motor vehicles) in many developed countries suffered setbacks and plummeted between 2007 and 2009, the demand for bearings rebounded. With the strong recovery of the motor vehicle industry and the rapid growth of durable goods manufacturing, the demand for bearings in these regions will also increase.

Considering that bearings are required for many daily necessities applications, extending bearing life and improving bearing performance to reduce waste generation during operation and reducing energy loss have become a general trend. In other words, making full use of existing machinery and reducing its impact on the environment is precisely the definition of environmental protection.

It is also worth noting that the bearing industry plays an important role in guiding engineers to develop new designs.

In this revolution, bearing manufacturers also shoulder heavy responsibilities. The teaching materials they provide ensure the correct and efficient use of equipment by end users, and help users and engineers understand bearing characteristics to achieve optimal mechanical performance is the ultimate interpretation of green environmental protection: Minimize the impact of humans on the environment and achieve sustainable development.

Recent related posts

09/10/2020

In the next two years, the world's bearing demand will reach 76 billion US dollars

According to the forecast analysis report of the global bearing market by the industry research company, the global demand for ball bearings, roller bearings and sliding bearings is expected to grow at an annual rate of 8.5%, reaching 76 billion US dollars by 2014, of which unloading The largest demand for ball bearings and roller bearings.

09/10/2020

Ice washing imitates air conditioner inverter wrestling or changes the industry pattern

nverter air conditioners have experienced more than ten years of difficult development in China and finally opened up in the Chinese market. "Inverter" has begun to win consumers' approval for its energy-saving and environmentally friendly features.

09/10/2020

How to identify the authenticity of imported air compressor accessories!

High-quality air compressor accessories are the basis for ensuring the normal operation of air compressor equipment. Due to the need for maintenance of air compressors and driven by benefits, a variety of imported engineering air compressors and air compressor accessories appear on the market, but the quality is uneven.

09/10/2020

How to choose the specifications of the air compressor

Once the air volume (m3/min) and pressure (Mpa(G)) requirements of the factory's air consumption are determined, the specifications of the air compressor can be selected. Factors you may want to consider when choosing include:

09/10/2020

How does the factory manage the air compressor room

As an important form of energy generation, air compressors are widely used in various industries, and there are many details in their maintenance. The service life of the air compressor can be prolonged after maintenance. Therefore, how to manage the air compressor room also plays a certain role in the maintenance of the air compressor.

09/10/2020

Existing problems in the promotion and application of water source heat pumps in my country

As a new type of cooling and heating method, water source heat pump should be quite mature and no problem from a technical point of view, especially from the point of view of heat pump units. However, considering China's national conditions and the promotion and application of water source heat pump cooling and heating as a whole system, there are still some problems:

09/10/2020

Ethylene plant training materials

Chapter One Typical Process of Ethylene Plant The first section sequence separation process Section 2 Front deethane process Section 3 Front depropanization process Section 4 Low investment separation process Section 5 Progressive separation process Section 6 Oil absorption and separation process Section 7 Comparison of six separation processes

09/10/2020

Discussion on Reasons and Protection of Air Compressor Motor Damage

Air compressor is abbreviated as air compressor. As a general-purpose mechanical equipment, it is widely used in the field of industrial and agricultural production. The problem is that the motor (three-phase asynchronous motor) as the power equipment of the air compressor generally has a higher failure rate than other motors.

09/10/2020

Design principle of vacuum oil filter

The vacuum oil purifier is designed according to the different principles of the boiling point of water and oil. It consists of a vacuum heating tank fine filter, condenser, primary filter, water tank, vacuum pump, oil drain pump and electrical cabinet.

09/10/2020

Copeland Special Compressor for Air Energy Water Heater and Its Application

A heat pump is a device that utilizes low-grade heat energy. The use of heat pumps to produce hot water can greatly reduce the consumption of primary energy and the CO caused by burning fossil fuels. Emissions. In China, the application and promotion of heat pump systems has entered a rapid growth track.

Customers frequently viewed

IWAYA DENKI Water Pump 25CJT0752

Panasonic Servo Motor MHMF022L1V2M

Honeywell Solenoid Valve VE4025B1045

ROTEN Mechanical Seal 8E5K-22-X

Galtech Gear Pump 1SPA0.9D-10N

Sanyo Denki Servo Motor P60B13150BXS1J

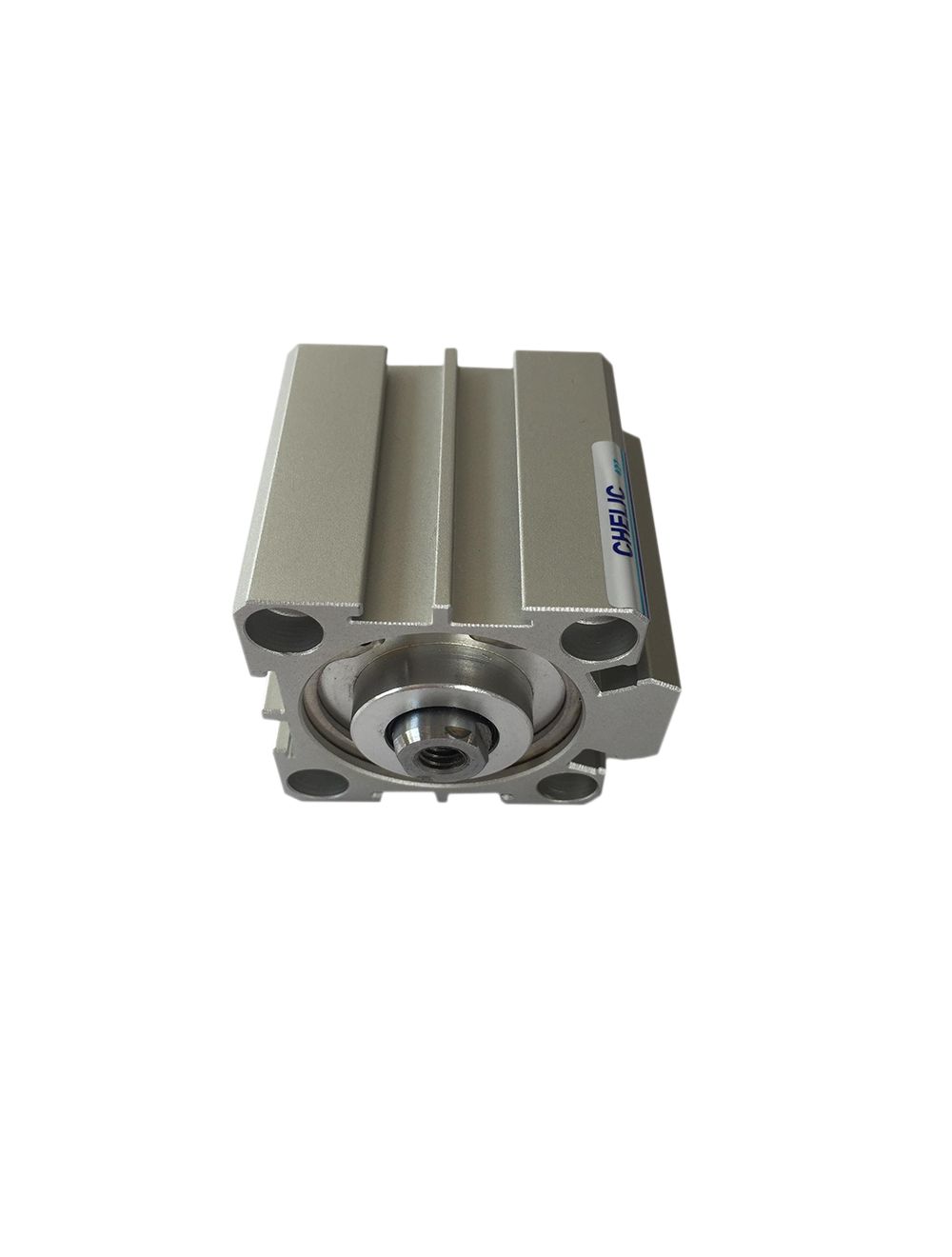

CHELIC Air Cylinder JGD80*10

SCHMERSAL Switch T2L 035-11Z-M20