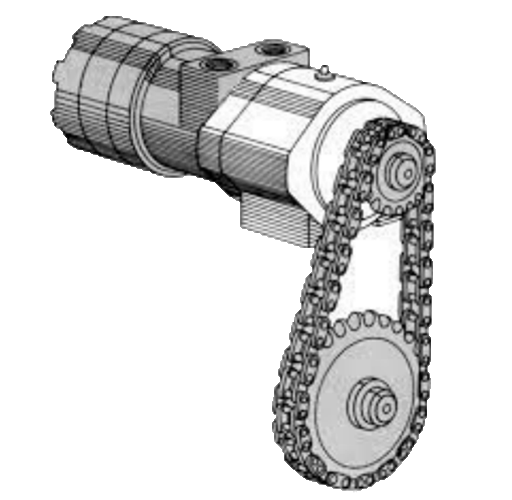

Figure 1: Hydraulic motor.

As one of the executive components of hydraulic system, hydraulic motor is particularly important in practical use. But what should we pay attention to in the installation process? When the transmission shaft of the hydraulic motor is connected with other machinery, it is necessary to ensure concentricity or adopt flexible connection. Please refer to the following steps for details.

1. Bearing of Hydraulic Motor

For motors that cannot bear radial force, it is not allowed to directly install belt pulley and other transmission parts on the main shaft. The driving sprocket is driven by a hydraulic motor, and the driven sprocket drives the conveyor belt roller. According to the users, the motor often leaks oil, and the oil leakage begins less than 3 months after the seal ring is replaced. What caused the oil leak? The hydraulic motor drives the pulley through chain drive. Because the chain drive will also produce radial force, the oil seal will deform after bearing the radial force, resulting in oil leakage.

Figure 2: The driving sprocket is driven by the hydraulic motor.

1.2 Hydraulic Motor Chain Drive

① The leakage oil pipe of the motor shall be unblocked, and generally it shall not be connected to the back pressure. When the leakage pipe is too long or connected to the back pressure due to some needs, its size shall not exceed the allowable value of the low-pressure seal.

② The external leakage oil should ensure that the motor housing is full of oil and prevent all the oil in the housing from flowing back to the oil tank during shutdown.

③ For the motor with long shutdown time, it cannot be operated directly at full load, and it should be used normally after idling for a period of time.

1.3 The Stand for Installing the Motor should Have Sufficient Rigidity

① The stand for installing the hydraulic motor must have sufficient stiffness to bear the reaction force exerted on the motor when it outputs torque.

② The insufficient rigidity of the frame installed with the motor will produce vibration or deformation, and even accidents, which cannot ensure that the concentricity of the connection between the drive machine. And the motor shaft is controlled within 0.1mm.

1.4 The Hydraulic Motor and Gearbox should not be Used Together

Figure 3: The stand of a hydraulic motor.

① One of the characteristics of hydraulic transmission is the large power to weight ratio, and generally, the hydraulic motor circuit itself can complete the usual speed regulation and speed change functions.

② If the hydraulic motor is used together with the gear box, it will lose the characteristics of hydraulic control and significantly increase the volume and cost of the equipment.

1.5 The Oil Drain Port of the Hydraulic Motor should be Returned to the Oil Tank Separately

① Although generally speaking, all the return oil pressures are not high, the return oil in many hydraulic systems still has a certain pressure, and the oil drain chamber of the hydraulic motor is not allowed to have pressure.

② The interior of the oil drain port of the hydraulic motor is connected with the housing cavity, and the shaft seal of the motor shaft only serves as a seal, not pressure resistant. If this port is connected with other oil return pipelines, it is easy to damage the motor shaft seal and cause oil leakage. Therefore, it is not allowed to connect the oil drain port of the hydraulic motor with other oil return pipelines.

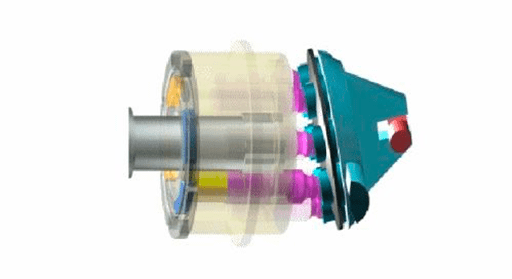

1.6 Air should not Enter the Hydraulic Motor

① During the initial operation of the hydraulic system, air will inevitably be contained in the pipeline of the system.

② An important part of system debugging is to exhaust the air in the system, which is particularly important for hydraulic motors.

③ There is a sudden change of hydraulic medium from high pressure to low pressure in the motor, and the frequency of this process is very high, with an average of about 10 times per revolution.

④ When the hydraulic oil entering the motor contains air, cavitation will occur locally at the sudden change of pressure, causing the motor to be damaged quickly.

Figure 4: Exhaust the air in the system.

Related Info

Hydraulic Motor TypesWhat is Hydraulic Motor

Troubleshooting of Hydraulic Motor

How to install a Vane Pump