What is Food Placement Machine?

A food placement machine is an important equipment in the automatic food production line.

It evenly arranges the formed food, such as moon cakes, bread, chocolate and other foods with solid shapes into the trays of standard specifications according to the set number of rows and columns, so as to carry out baking or heating and other subsequent production processes.

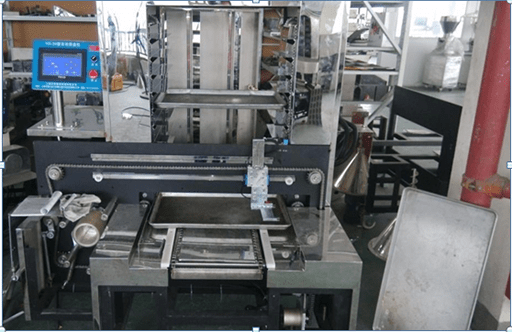

Figure 1: What is food placement machine looks like.

How Food Placement Machine Works?

Cake conveying action: After the food material is in place, which is detected by photoelectric encoder, the whole conveyor belt is pushed to move right horizontally by the X-axis servo to complete the cake falling action.

Tray pushing action: After one line of cake falling is completed, X axis returns to the origin, and Y-axis servo pushes the tray to a certain distance (according to the process setting),then the second line of cake falling begins.

Cake falling action: After the whole cakes in a tray fall into a container, X axis and Y axis return to the origin. Falling motor operates to drop the new tray, which is pushed out from Y axis.

Figure 2: Work flow of a food placement machine includes cake conveying, tray pushing and cake falling.

Components of Food Placement Machine

Electrical components used in a food placement machine include:

HMI:AH700ELK *1

PLC:AP-224BT-A *1

SERVO:JSDEP-20A *2

INV:S310-201*1

Figure 3: Components and the organizing structure of food placement machine.

PLC and HMI communicate by RS232; PLC and S310 communicate with the RS485 interface to control the frequency setting, start and stop of the conveyor belt frequency converter; PLC sends out pulse and direction signals to control servo operation, and receives alarm feedback signals from servo and frequency converter.

Food Placing Test With Teco JSDEP

Here are three placement modes.

Square Mode

The number of cake per row in the tray and the position of the first column are fixed.

Interactive Mode

The effect of interactive mode is as shown in figure 4.

Figure 4: Work result of food placement in interactive mode.

Straight Line Mode

Straight line mode is similar to the square mode. The difference is that after detecting the cake falling by photoelectricity encoder, the X axis goes directly to the whole row distance. The number of cake falling of each row is determined by the production speed.

Pros of Teco JSDEP for Automatic Food Placement

AH series touch-screen function setting is convenient for customers to store data, and adapt to the production of multiple specifications of products.

The machine runs steady and efficiently, with better production speed and precision performance than the same type of food placement machine.

Set up three food placement modes: square, interactive and straight line, which are convenient for customers with different needs.

Shop Teco Servo Drive on OKmarts