Video: What Parts Does the Servo System Consist of? (Basic Components, Working Principle, Application)

Figure 1: Servo motors.

A servo system refers to a system that can perform desired movements according to external instructions, achieving automatic control of output quantities including position, direction, status, etc. It is not only a key link in industrial automation, but also a necessary way to achieve precise positioning and precise movement.

This article will briefly introduce the composition, working principle, and types of the servo system.

1. Structure and Components of the Servo System

From the perspective of automatic control theory, servo control systems generally include five parts: controller, controlled object, execution link, detection link, and comparison link.

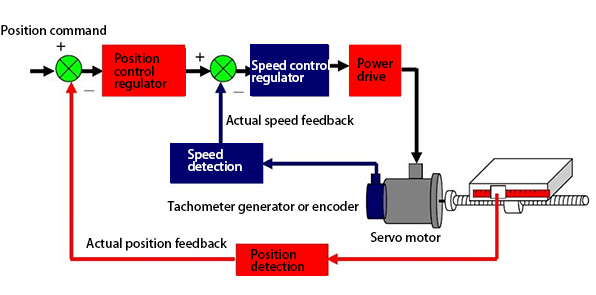

Figure 2: Servo system composition principle block diagram.

1. Comparison link

The comparison link is a link that compares the input command signal with the feedback signal of the system to obtain the deviation signal between the output and the input. It is usually implemented by a specialized circuit or computer.

2.Controller

The controller is usually a computer or PID control circuit, and its main task is to transform and process the deviation signal output by the comparison element to control the actuating element to act as required.

3. Execution link

The function of the execution link is to convert various forms of input energy into mechanical energy according to the requirements of the control signal to drive the controlled object to work. The actuating elements in mechatronics systems generally refer to various motors or hydraulic and pneumatic servo mechanisms.

4. Controlled object

The controlled object refers to the object being controlled, such as a robotic arm.

5. Detection link

The detection link refers to a device that can measure the output and convert it into the dimensions required by the comparison link, generally including sensors and conversion circuits.

2. Servo System Working Principle

The servo system is mainly composed of servo drive, encoder, servo motor and other components. Its working principle diagram is shown in the figure below:

Figure 3: Servo system working principle diagram.

The servo system is an automatic control system that enables the controlled quantities of the output such as the position, direction, and state of the object to change as the input target (or given value) changes.

After receiving the control command, the servo drive will send a signal to the servo motor to make it rotate. At the same time, the encoder embedded in the motor will feed back the motion parameters of the servo motor to the servo drive, and the servo drive will complete the summaries, analysis and corrections of the signal. As a result, the servo system accurately controls the output variables of the actuating element (mechanical transmission device such as motor) in a closed-loop form.

3. Servo System Types

Commonly used control methods of the servo control motors mainly include: open-loop control, semi-closed-loop control, and closed-loop control.

The drive system of the closed-loop system has a position (or speed) feedback link while the open-loop system does not have a position and speed feedback link.

3.1 Open Loop Servo System

There is no position measuring device in an open loop servo system, and the signal flow is one-way (CNC device → feeding system).

Without position feedback, the accuracy is not high compared to the closed-loop system. Its accuracy mainly depends on the performance and accuracy of the servo drive system and mechanical transmission mechanism. Generally, stepper motors are used as servo drive components.

This type of system has the advantages of simple structure, stable operation, convenient debugging, simple maintenance, and low price. It is widely used in situations where accuracy and speed requirements are not high and the driving torque is not large. It is generally used in economical CNC machine tools.

Figure 4: Open loop servo system.

3.2 Closed Loop Servo System

The fully closed-loop CNC system directly detects the actual position of the moving parts.

Theoretically, it can eliminate errors, clearance and lost motion in the entire drive and transmission links, and achieve high position control accuracy. Since the friction characteristics, rigidity and clearance of many mechanical transmission links in the position loop are non-linear, it is easy to cause system instability, making the design, installation and debugging of the closed-loop system quite difficult.

This system is mainly used for boring and milling machines, super-precision lathes, super-precision grinders and larger CNC machine tools that require high precision.

Figure 5: Closed loop servo system.

3.3 Semi-Closed Loop System

The position sampling point of the semi-closed-loop CNC system is shown in the figure. It is taken from the drive device (servo motor is commonly used) or leading screw, and the rotation angle is sampled for detection. It does not directly detect the actual position of the moving parts.

The semi-closed loop contains no or only a small number of mechanical transmission links, so it can obtain stable control performance. Because motion errors caused by leading screw pitch error and gear backlash are difficult to eliminate, its accuracy is worse than that of closed loop and better than that of open loop.

The semi-closed-loop CNC system has a simple structure, easy debugging, and high accuracy, so it has been widely used in modern CNC machine tools.

Figure 6: Semi-closed loop system.

Open-loop servo systems, closed-loop servo systems and semi-closed-loop servo systems are all common control systems, and they have huge differences in control effects, accuracy and price. Choosing an appropriate servo system requires considering the specific application scenarios and needs to achieve the best control effect.