- Refrigeration Compressors

- Servo Valve

- VFD

- Soft Starter

- Solenoid Valve

- Transmitter

- Transformer

- Expansion Valve

- Solenoid Coil

- Sensor

- Safety Valve

- Check Valve

- Electric Motor

- Overflow Valve

- Butterfly Valve

- Combustion Controller

- Piston Pump

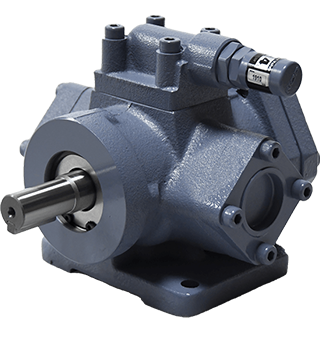

- Gear Pump

- Ball Valve

- Hydraulic Motor

- Sight Glass

- Relay

- Expansion Valve Coil

- Filter

- a

- b

- c

- d

- e

- f

- g

- h

- i

- j

- k

- l

- m

- n

- o

- p

- q

- r

- s

- t

- u

- v

- w

- x

- y

- z

- 3

- 7

Gear pump

The gear pump is a rotary pump that relies on the change and movement of the working volume formed between the pump cylinder and the meshing gear to deliver or pressurize the liquid. Two closed spaces are composed of two gears, the pump body and the front and rear covers. When the gears rotate, the volume of the space on the side where the gears are disengaged increases from small to large, forming a vacuum to suck the liquid, and the volume of the space on the side where the gears mesh changes from large to large. Small, and the liquid is squeezed into the pipeline. The suction chamber and the discharge chamber are separated by the meshing line of two gears. The pressure at the outlet of the gear pump depends entirely on the resistance at the outlet of the pump.

Working Principle

When the volume of the pump chamber is increased (as the diaphragm moves up), the pressure drops. So, the fluid is drawn into the chamber. As the diaphragm moves down and volume decreases, the chamber pressure increases. Then, the drawn fluid is pushed out. Finally, the diaphragm, which moves again upwards, draws fluid into the chamber and completes the cycle. This procedure is similar to what occurs in an internal combustion engine.

Diaphragm Pumps provide a tight seal between the drive device and the compression chamber, enabling the pump to move, compress, and evacuate the medium without the need for lubrication.An elastomeric diaphragm is a versatile and dynamic seal that eliminates many other sealing methods limitations. In addition to not leaking, it offers little friction and can be created for low-pressure sensitivity. With suitable materials, diaphragms can seal over various pressures and temperatures without requiring lubricant or maintenance.

Types of Gear Pump

As the most common type of positive displacement pumps, gear pumps are usually selected when applications call for constant flow, high pressure, high viscosities, or special requirements for certain fluids. Gear pumps come in several forms. Depending on the application, one type of gear pump may offer superior features over the others. All are self-priming pumps and deliver smooth pulse-less flows.Typically, there are two types of gear pumps.Based upon the design, the gear pumps are classified as

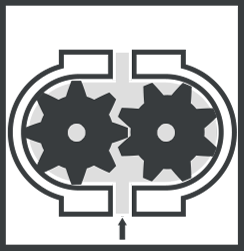

External Gear Pumps

External gear pumps consist of two identical, interlocking gears (driver and driven gears) that are placed inside the casing and supported by separate shafts, and rotate in opposite directions. External gear pump designs can utilize spur, helical, or herringbone gears.

The mechanism is usually driven by one of the toothed gears, which in turn drives the other. When the gears on the pump suction side come out of interlocking, the volume increases at the suction side. As these gears begin to spin against the pump housing, fluid moves into the cavity and traps by the teeth of the gears. This trapped liquid travels around the housing from inlet to outlet. When the gear teeth mesh on the pump outlet side, the volume reduces, and the liquid is forcibly drained under pressure.

External gear pumps tend to be less expensive and easier to operate than internal gear pumps. They are most commonly used lubrication pumps in machine tools, in fluid power transfer units, and as oil pumps in engines.

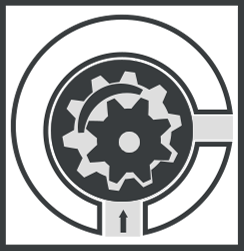

Internal Gear Pumps

In these types of gear pumps, the inner gear is the smaller one and has external teeth and the outer gear is the bigger gear and has internal teeth.

The principle of operation of internal gear pumps is the same as external gear pumps. When the gears on the suction side of the pump are disengaged, the volume increases. As the gears continue to turn relative to the pump housing and diaphragm, the liquid moves into the cavity and imprisons by the teeth of the gears. This trapped liquid travels around the housing from inlet to outlet. When the gear teeth mesh on the pump outlet section, the volume reduces, and the liquid forcibly drains under pressure.

Internal gear pumps are versatile, reliable, and easy to maintain. They are preferred to external gear designs in applications involving higher viscosity fluids, at high temperatures, and with fluids containing solids. Typically, internal gear designs operate at lower rotational speeds than external gear designs, have greater clearances, and are therefore less susceptible to wear in these applications.

Applications

Gear pumps are usually used to pump oil, paints, resins, or food products that have a high viscosity. In any application that requires precise dosing or high-pressure output, they are the best choice. In situations where the supply is irregular, gear pumps are also preferred because their output is not much affected by pressure.

Below are some examples of typical external and internal gear pump applications:

Automotive fuels and oils.

Hydraulic oils.

Solvents and alcohol.

Hot oil circulation on a small scale.

Paints, resins, and polymers.

Liquid soap.

Edible foods such as corn syrup, animal food, and peanut butter.

Operational Characteristics

In order to enhance the performance of a gear pump, friction between its parts needs to be reduced. During friction, heat is generated, which in turn causes a gear pump’s components to expand physically. Due to their tight mechanical clearances, gear pumps, particularly external gear pumps, are susceptible to thermal expansion damage. For instance, gear teeth might become misaligned, which would result in wear, leaks, and a consequent decrease in efficiency. An improperly aligned gear pump may seize (be unable to rotate) in severe cases.

It is common for the fluid being pumped to serve as lubricant for the pump’s internal components. As a result, most gear pumps are inefficient when dry (without fluid flow) for prolonged periods of time.

A gear pump is most efficient when running at its maximum design speed. A lower revolution per minute (rpm) will result in lower pump efficiency.

The tight tolerances of gear pumps mean they are not a good choice for pumping liquids with solids since this would damage the gears and other components of the pump. Furthermore, gear pumps generally do not achieve as high flow rates as centrifugal pumps when operating under lower discharge pressures. Also, gear pumps are usually run at lower speeds than centrifugal pumps (generally 300-600 RPM), requiring gear reducers or belt drive systems. Higher viscosity liquid requires a gear pump with a lower rotation speed.

A gear pump is a positive displacement pump, so its flow rate is relatively low (a “fixed” flow rate) regardless of whether the discharge pressure increases or decreases. Consequently, with an increase in discharge pressure, horsepower requirements will increase. As viscosity increases, the horsepower required for a given gear pump will also increase (this results in an increase in discharge pressure in the piping system due to increased friction losses caused by the more viscous liquid on the walls of the pipes and other plumbing components).

Media Type

Selecting the right gear pump requires an understanding of the properties of the liquid in the addressed system.

These properties include viscosity and consistency.

Viscosity is a measure of the thickness of a liquid. Viscous fluids like sludges generate higher systems pressures and require more pumping power to move through the system. Internal gear pumps tend to be better suited than external gear pumps on highly viscous fluids and vice versa.

Consistency is the material makeup of the liquid solution in terms of chemicals and undissolved solids. In most cases, gear pumps are not able to pump solutions with suspended solids because of the associated wear and degradation of the drive assembly. Solutions with corrosive chemicals should be handled by pumps with materials and parts designed to withstand corrosion.

Advantages and Disadvantages of Diaphragm Pumps

Advantages: simple and compact structure, small size, light weight, good craftsmanship, cheap price, strong self-priming, insensitive to oil pollution, large speed range, impact load resistance, convenient maintenance, and reliable operation.

Disadvantages: unbalanced radial force, large flow pulsation, high noise, low efficiency, poor interchangeability of parts, difficult repair after wear, and cannot be used as a variable displacement pump.