- a

- b

- c

- d

- e

- f

- g

- h

- i

- j

- k

- l

- m

- n

- o

- p

- q

- r

- s

- t

- u

- v

- w

- x

- y

- z

- 3

- 7

Screw Pump

Screw pump, also known as "screw pump", "Archimedes screw pump". A pump that uses the rotation of the helical blade to make the water body spiral upward in the axial direction. It consists of a shaft, a spiral blade, and a casing. When pumping water, place the pump obliquely in the water so that the inclination angle of the main shaft of the water pump is smaller than the inclination angle of the helical blade, and the lower end of the helical blade is in contact with the water. When the prime mover drives the screw pump shaft to rotate through the speed change device, the water enters the blades and rises along the spiral flow path until it flows out. Simple structure, easy manufacture, large flow rate, small water head loss, high efficiency, easy repair and maintenance, but low head and low speed, need to install a speed change device. It is mostly used for irrigation, drainage, and lifting of sewage and sludge.

Working principle

When the volume of the pump chamber is increased (as the diaphragm moves up), the pressure drops. So, the fluid is drawn into the chamber. As the diaphragm moves down and volume decreases, the chamber pressure increases. Then, the drawn fluid is pushed out. Finally, the diaphragm, which moves again upwards, draws fluid into the chamber and completes the cycle. This procedure is similar to what occurs in an internal combustion engine.

Diaphragm Pumps provide a tight seal between the drive device and the compression chamber, enabling the pump to move, compress, and evacuate the medium without the need for lubrication.An elastomeric diaphragm is a versatile and dynamic seal that eliminates many other sealing methods limitations. In addition to not leaking, it offers little friction and can be created for low-pressure sensitivity. With suitable materials, diaphragms can seal over various pressures and temperatures without requiring lubricant or maintenance.

Working principle

The device of the screw pump includes three parts: the prime mover, the variable speed transmission device and the screw pump, which is composed of the screw blade, the pump shaft, the bearing seat and the casing. The screw pump is installed obliquely between the upper and lower pools, and the lower blades of the screw pump are immersed below the water surface. When the pump shaft rotates, the helical blades push the water in the pool into the leaf groove, and the water is lifted up step by step along the helical shaft under the action of the rotating blades of the helix until it reaches the water outlet of the helical pump. The screw pump only changes the potential energy of the fluid, which is different from the vane water pump, which converts mechanical energy into the potential energy and kinetic energy of the transported liquid.

Types of Screw Pump

Screw pumps come in a variety of types and are available on the market. Below are brief explanations of the most types of screw pumps:

One Screw Pumps

Two Screw Pumps

Three Screw Pumps

Four Screw Pumps

Five Screw Pumps

One Screw Pump

PC pumps, worm pumps, single, and progressive cavity pumps are all names for one screw pumps. In general, these pumps are not regarded to be part of the screw-pump family since the rotor is not shaped like a screw but rather like a crumpled round shaft.

These types of screw pumps are reversible. They operate on the positive displacement principle. They are made up of two spiral elastomer stators and a single spiral metal rotor. These pumps are appropriate for liquids that require a constant, non-pulsating flow.

One screw pumps are well-known for their high suction capacity. They are used in a variety of applications such as transportation, oil and gas, paint, sewage, papers, ceramics, chemicals, and so on. These pumps may operate abrasive and non-abrasive fluids with or without solid components (bilge water, sludge, sewage, and so on) as well as food (ketchup, yeast, gelatin, etc.). These types of screw pumps are quite inexpensive. Also, they do not clog.

Two Screw Pump

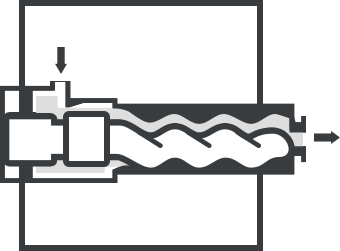

Also known as a twin-screw pump (double screw pump), these types of pumps are commonly used for high-power applications such as heavy oil tube transfer. The screws in the pumps are powered by the motor, and timing gears are commonly used to turn the next screw.

These types of screw pumps are self-priming as well as rotating. Because of their excellent performance, these pumps are used in the food, energy, marine, and petrochemical sectors. The following are the characteristics of the two screw pumps:

They can function at varying speeds

They can run dry

They have a low NPSH need

They can handle a high volume of fluids and viscosities

They tolerate pollution

They have a low liquid sheer

They are extremely reliable

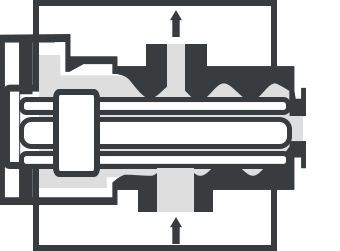

Three Screw Pump

These types of screw pumps are also referred to as “triple-screw pumps”. Without the use of timing gears, the screws in the pump are decided by the motor to rotate the remaining two screws that surround it. They are made up of three screws and an electric motor that powers the screws. It has one driver and two screws that are driven. The electric motor powers the driver screw, which in turn powers the driven screws. These screws are intertwined.

Three screw pumps are used in minor applications like lubricating systems.

In addition to the above three types of screw pump, there are four screw pump and five screw pump two types of screw pump, they all belong to the multi-screw pump.

Multi - screw pump has double screw pump, three screw pump, five screw pump. One of the pumps is an active screw, a right - handed convex screw, the rest of the driven screw, a left - handed concave screw.

Four Screw Pump

In general, these types of screw pumps are a two-screw pump with two screws on each rotor, however, each pump rotor contains two screws that revolve in opposing directions.

The four screw pump suctions fluid into the suction port, which is then divided evenly and sent to both ends of the pump. The two-fluid streams run through the pump to the center and then rejoin before entering the discharge outlet. The four-screw pump, like the twin-screw pump, uses timing gears to drive the second rotor. Four screw pumps are commonly utilized in multi-phase applications and oil transfer pipes. Four screw pumps are commonly used in multi-phase and oil pipeline applications.

Five Screw Pump

All four screws are driven by a single driving rotor.

The operation of these types of screw pumps is quite similar to that of a three-screw pump. However, instead of three screws, it employs five. These pumps, like three-screw pumps, have a single diving rotor that drives all of the remaining screws. These pumps are widely utilized in a variety of applications, including hydraulic and pipe oil.

Applications of Screw Pump

There are several lubricating and hydraulic machines on the premises. To provide oil to huge equipment, utilize screw pumps.

Screw pumps are better for pumping heavier oils. They can even pump liquids with higher viscosity and higher flow rates.

These pumps are capable of pumping both liquid and gas at the same time. As a result, these pumps are used in a variety of pumping businesses.

The oil and gas, mining, and industrial industries all employ this pump.Ceramics, paint, food, chemicals, and paper industries all employ these pumps.

Advantages and Disadvantages of Screw Pumps

The following are the benefits and drawbacks of a screw pump:

Advantages of Screw Pump

Compared to centrifugal pumps, screw pumps have some benefits. First, there is no turbulence as the pumped liquid flows axially. This prevents bubbles from forming in thick liquids.

Screw Pumps can be used for all fluids

These pumps have easy maintenance.

It has a compact construction

It can run dry

These have a quiet operation

These pumps provide a steady, non-pulsing flow of fluid.

This pump has higher volumetric efficiency.

High reliability

It needs very low maintenance

High robustness

Self-priming ability

It is very resistant to dust particles and water vapors.

The contamination of the fluid is not pumped by a screw pump.

You can also pump a high viscous liquid with screw pumps without losing the flow.

It has a frictionless rotation

It pumps the fluid at a very high speed

It has very high efficiency

Low pulsations

Disadvantages of Screw Pump

High cost for installation.

A gas ballast must needed for transmitting the light gas.

The pumping speed and pressure will be a little slower without a gas ballast when transmit the light gas.