- a

- b

- c

- d

- e

- f

- g

- h

- i

- j

- k

- l

- m

- n

- o

- p

- q

- r

- s

- t

- u

- v

- w

- x

- y

- z

- 3

- 7

Vane Pump

When the vane pump rotor rotates, the tip of the vane clings to the inner surface of the stator under the action of centrifugal force and pressure oil. In this way, the working volume formed by the two blades, the rotor and the inner surface of the stator first absorbs oil from small to large and then discharges oil from large to small. When the blades rotate one circle, oil absorption and oil discharge are completed once.

Working principle

When the vane pump rotor rotates, the tip of the vane clings to the inner surface of the stator under the action of centrifugal force and pressure oil. In this way, the working volume formed by the two blades, the rotor and the inner surface of the stator first absorbs oil from small to large and then discharges oil from large to small. When the blades rotate one circle, oil absorption and oil discharge are completed once.

Types of Vane pump

There are mainly three types of vane pumps, each type has its own set of benefits.

Unbalanced Vane Pumps

Unbalanced vane pumps are made up of a cylindrical rotor that is offset inside a circular housing. It signifies that the centers of the cylindrical rotor and the shell do not coincide. The casing’s center and the rotor’s center are some distance apart. No leakage exists between the housing and the vane tip. Due to pressure variations between the intake and exhaust ports, a side thrust is formed on the rotor shaft. The bearing life is reduced due to the lateral force on the shaft. These types of vane pumps are known as an “imbalanced vane pumps” because of pressure fluctuations between the input and exhaust ports. There is no side force on the rotor shaft in a balanced vane pump.

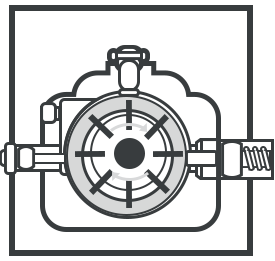

Balanced Vane Pumps

The balanced rotary vane pump has an elliptical casing. The elliptical casing and rotor have the same center. There isn’t any offset. These types of vane pumps are designed to be adaptable and are commonly used in mobile and industrial applications. Because these pumps have two inlets and two outlet, there is no pressure differential between the inlets and outputs. The two entrance ports are on opposing sides of the machine. Similarly, the outlet ports are on opposing sides as well. The intake and outlet port assembly balance equal and opposing thrust forces so that the rotor shaft is not subjected to lateral thrust forces. This balancing pump provides superior performance and long service life in a variety of applications. Balance vane pumps have a service life of more than 24,000 hours in industrial applications. The size of the cavity between two vanes decreases from intake to exit. The pump draws fluid in through the intake port and discharges it through the output port. The rotor is under high pressure in the exit area, and the forces in the two outlet zones are equal but opposing. As a result, there is no net load on the shaft’s bearings.

Variable Displacement Vane Pumps

Variable displacement vane pumps allow you to alter the size of the pocket; the delivery rate changes as a result of the varied sizes of the pump pocket. The vanes on these types of vane pumps do not come into direct contact with the pump housing. A ring separates the vane from the casing in this rotary vane pump. The response ring is the name given to this ring. One end of this ring is attached to the spring, while the other end is attached to the adjusting screw. The adjustment screws modify the size of the pump pocket. As the adjustment screw begins to rotate, the response ring travels up and down. The offset between the rotor center and the response ring center changes as the reaction ring swings up and down. As the offset varies, the size of the pocket changes, affecting the pump’s delivery flow rate.

Applications of Vane pump

Typical applications in which vane pumps are used are:

Transfer of LPG

Fuel loading and transmission in automotive and aviation systems

Refrigeration coolants: ammonia, freons

Chemical industry: transfer of acids, solvents, aqueous solutions

Solvents, aqueous solutions

Drinks dispensers

What are the advantages of a vane pump?

Vane pumps are ideal for pumping low to medium viscosity liquids, including those with entrained gases, and can give an accurate, smooth, low pulsation output. With a varying feed pressure, a vane pump will continue to provide a constant flow. They are especially noted for their dry priming, ease of maintenance, and good suction characteristics over the lifetime of the pump. There is no internal metal-to-metal contact and the pumps self-compensate for wear through vane extension. Vane pumps can handle thin liquids at relatively high pressures and can run dry for short periods. They are also reversible so can be used to load and unload a vessel and also ensure liquid is fully recovered from delivery hoses.

How To Choose Vane Pump Parameter Specifications?

1 Rated pressure selection. The rated pressure of the vane pump products is 7MPa, 1OMPa, 16MPa, 2lMPa, 25MPa, 28MPa and 30MPa. The same vane pump products use different working media and different rotational speeds, and their rated pressures are also different from each other. Select the appropriate vane pump for working medium, speed and working pressure.

2 The principle of selection of nominal displacement, speed, drive power and multi-pump parameters is the same as that of gear pumps.

3 Selection considerations. Low-noise vane pump products, such as sub-vane pump and pin vane pump, should be used indoors and in applications where environmental noise is required. In general, the noise of a double-acting vane pump is lower than that of a single-acting vane pump, but some single-acting vane pumps that take some measures technically do not have much noise. The life and price factors of the vane pump should be considered comprehensively. Especially when selecting the variable vane pump or the double-acting vane pump, it is necessary to compare the energy saving effect and cost.