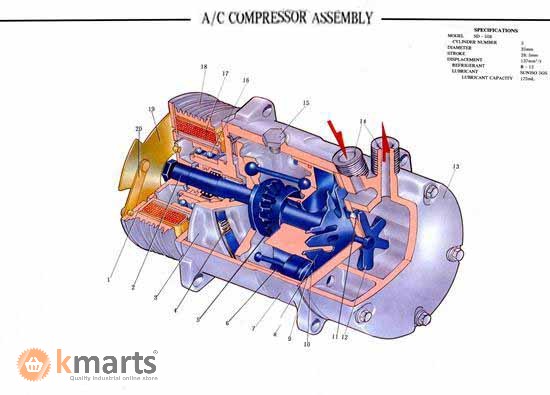

Can the car compressor be repaired Car air conditioner compressor disassembly diagram

Many people ask whether car air-conditioning compressors can be repaired. In fact, car air-conditioning compressors can be repaired. However, car air-conditioning compressors are usually repaired by special maintenance organizations. Auto repair shops only check and diagnose car air-conditioning failures, that is, car air-conditioning Compressors are rarely disassembled. The following editor will show you the inspection of automobile air-conditioning compressor failures and the dismantling diagram of automobile air-conditioning compressors. Interested friends will find out together.

Common failures and failure reasons of automobile air-conditioning compressors are as follows:

(1) The compressor has abnormal noise, the possible reasons are:

① The compressor suction valve or discharge valve is damaged;

②The bearing is worn and its clearance is too large;

③The internal connecting rod bolts are loose;

④The pulley bearing is damaged;

⑤The clutch lock nut is loose;

⑥The clutch driven disc is deformed.

(2) The compressor does not function as a pump or the pump capacity is insufficient. The reasons for the failure are:

①The valve plate gasket is broken;

②Broken intake valve or exhaust valve;

③The piston and cylinder wall are worn and the gap is too large;

④The electromagnetic clutch cannot be engaged or slipped

2. Disassembly of the compressor

If it is determined that the compressor itself is faulty, the compressor needs to be removed for maintenance or replacement. The disassembly method of the compressor is as follows:

(1) Disconnect the connecting wire of the compressor electromagnetic clutch.

(2) Discharge the refrigerant.

(3) Remove the alternator and loosen the drive belt.

(4) Remove the fastening nut and disconnect the suction and discharge pipelines from the compressor. After disconnecting the pipeline, immediately plug or cover the pipeline interface to prevent moisture and dust from polluting the system.

(5) After loosening the fastening bolts, remove the compressor.

(6) Discharge the oil in the compressor, measure and record the amount of oil discharged with a measuring cup, and check whether the discharged oil has metal particles, discoloration or dirt.

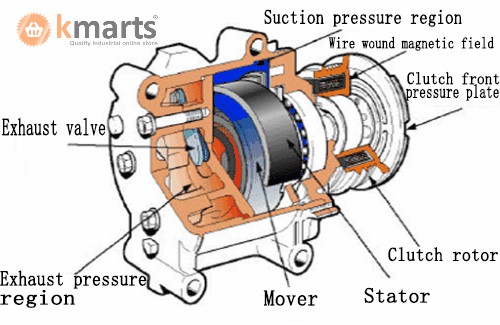

(7) Remove the compressor electromagnetic clutch fasteners and remove the electromagnetic clutch.

3. Troubleshooting of compressor and clutch

(1) Overhaul the compressor. The general auto repair shop does not disassemble the compressor. If it is confirmed that the compressor cannot be pumped or the noise during the operation of the air conditioner is caused by the compressor itself, the compressor needs to be replaced.

(2) Check the compressor clutch. The method is as follows:

① Check whether the plated parts of the compressor clutch pressure plate are discolored, peeled or damaged. If so, replace the clutch assembly;

② Turn the pulley by hand to check the compressor pulley bearing If there are noises, gaps or excessive blocking during rotation, replace the clutch assembly;

③Check the resistance of the clutch solenoid coil, the two ends of the compressor clutch solenoid coil should be a path

4. Installation of compressor

The installation of the compressor is carried out in the reverse order of disassembly. When installing the compressor, pay attention to:

(1) A new O-ring should be replaced at each joint, and a little frozen lubricating oil should be applied during installation, and an O-shaped groove suitable for the refrigerant must be used;

(2) Do not pour the used refrigerating lubricating oil back into the container to avoid pollution, and it should not be mixed with other refrigerating lubricating oil.

5. Check after installation

The following inspections should be made after the compressor is installed:

(1) Check for leaks and add refrigerant.

(2) Check that the tension of the compressor transmission belt should be 250N·m with a tension tester. If the tension is not enough, adjust it.

(3) Check the oil level of the compressor and insert the compressor dipstick from the filler plug. If the dipstick cannot be fully inserted (the dipstick is inserted until its curved bottom surface is flush with the surface of the filler port), the compressor clutch drive disc must be turned Then insert the dipstick to check the oil level.

(4) Check whether the compressor clutch works normally, apply battery voltage to the electromagnetic clutch, and the compressor should work; as soon as the electromagnetic clutch is disconnected from the power supply, the compressor will stop working immediately.

(5) Test the performance of the air conditioning system.