Valves are indispensable components in various industries and applications, serving the crucial role of regulating the flow of fluids or gases. With a myriad of valve types available, each designed to fulfill specific functions and requirements, understanding their differences and applications is essential.

In this comprehensive guide, we will explore the diverse world of valves, examining different types, their constructions, operations, applications, and advantages.

Before delving into the types of valves, let’s first learn more about valves basics.

1. What are Valves and How Do They Work?

Valves are mechanical devices designed to control the flow of fluids or gases by opening, closing, or partially obstructing passageways within a system. They consist of a movable element, such as a disc, ball or plug, which can be manipulated to regulate the flow of the fluid. Valves operate based on different principles, including linear motion, rotary motion, and diaphragm action, depending on their design and construction.

The basic operation of a valve involves controlling the flow of fluid by adjusting the position of the movable element. When the valve is open, the fluid can flow freely through the passageway, while closing the valve restricts or stops the flow altogether. Valves can be actuated manually, such as through a handwheel or lever, automatically, or actuated by using pneumatic, hydraulic, or electric actuators.

The key components of a valve include the body, which houses the internal mechanism and provides connections for piping, the closure element, which controls the flow, and the actuator, which is responsible for operating the valve. Additionally, valves may feature ancillary components such as seals, gaskets, and packing materials to ensure leak-tightness and proper functioning.

2. 8 Different Types of Valves and Their Applications

1. Most valves fall within two categories:

●Rotary Valves (also referred to as “quarter-turn” valves): such as butterfly valves, plug valves and ball valves.

●Linear Valves (including rising stem (multi-turn) and axial valves): such as globe valves, gate valves and needle valves

2. According to different actuation methods, valves can be divided into three categories:

●Automatic Valves: such as pressure reducing valves, relief valves, safety valves, check valves and steam traps.

●Actuated Valves: including electric valves driven by electricity (electric motor), pneumatic valves driven by compressed air, hydraulic valves driven by the pressure of liquid such as oil, and solenoid valves driven by a solenoid coil (electromagnet).

In addition, there are electro-hydraulic valves which are actuated by solenoids and liquid pressure.

●Manual Valves: Typically adjusted by hand, these valves use handwheels, hand levels, gear wheels, or chains to actuate.

The following introduces the detailed information about common types of valves.

2.1 Ball Valves

Ball valves are commonly used for on/off control in applications where tight shut-off is required. They consist of a spherical closure element (the ball) with a hole, which is rotated to control the flow. When the hole is aligned with the flow direction, the valve is open, and when it is perpendicular, the valve is closed.

Ball valves are versatile, durable, and suitable for a wide range of applications, including water supply, gas pipelines, and chemical processing.

2.2 Gate Valves

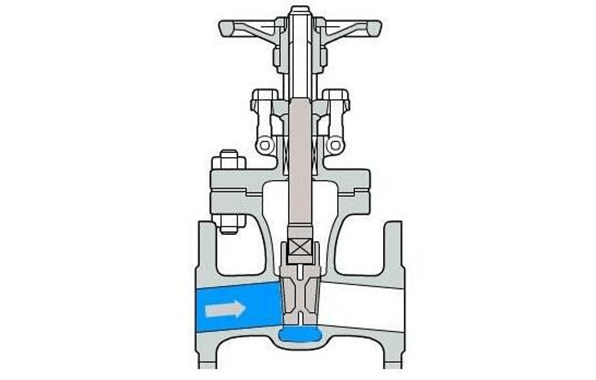

Gate valves are designed for full flow or no flow applications, where a straight-line flow of fluid with minimum restriction is desired. They feature a gate-like closure element that is raised and lowered to control the flow.

Gate valves provide excellent shut-off capabilities but are not ideal for throttling or regulating flow due to their design. They are commonly used in industries such as oil and gas, wastewater treatment, and power generation.

2.3 Globe Valves

Globe valves are characterized by their spherical body shape and a movable disk-like element (the plug) that regulates flow. The plug is connected to a stem, which is controlled by a handwheel or actuator.

Globe valves offer precise control over flow rate and are often used for throttling applications where flow regulation is critical. They are prevalent in industries such as HVAC, steam systems, and chemical processing.

2.4 Butterfly Valves

Butterfly valves feature a circular disc (the butterfly) that rotates around a central axis to control flow. When the disc is parallel to the flow direction, the valve is fully open, and when it is perpendicular, the valve is closed.

Butterfly valves are lightweight, compact, and offer quick operation, making them suitable for large-diameter applications where space is limited. They are commonly used in HVAC systems, water treatment plants, and irrigation systems.

2.5 Check Valves

Check valves, also known as non-return or one-way valves, allow fluid to flow in only one direction, preventing backflow. They feature a hinged or spring-loaded disc that opens to allow forward flow and closes to prevent reverse flow.

Check valves are essential for maintaining system integrity and preventing damage caused by backflow. They are found in various applications, including pumps, compressors, and plumbing systems.

2.6 Needle Valves

Needle valves are precision valves designed for fine control of flow rate in low-pressure systems. They feature a long, tapered needle-like stem that fits into a conical seat, allowing for precise adjustment of flow by rotating the stem.

Needle valves are commonly used in instruments, laboratories, and hydraulic systems where precise flow control is required.

2.7 Diaphragm Valves

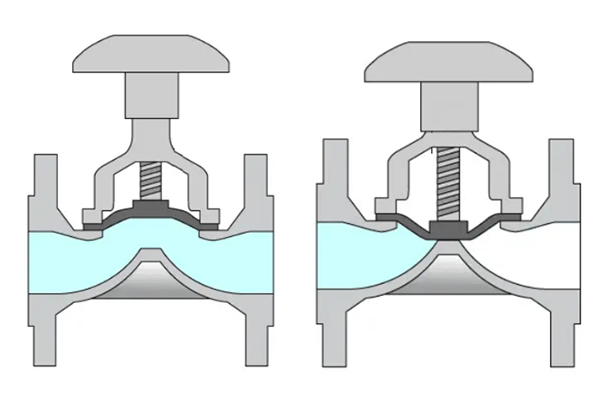

Diaphragm valves utilize a flexible diaphragm as the closure element to control flow. The diaphragm is raised or lowered by a stem, which is actuated manually or pneumatically.

Diaphragm valves are ideal for handling corrosive or abrasive fluids, as the diaphragm isolates the fluid from the valve body. They are commonly used in pharmaceutical, chemical, and wastewater treatment industries.

2.8 Solenoid Valves

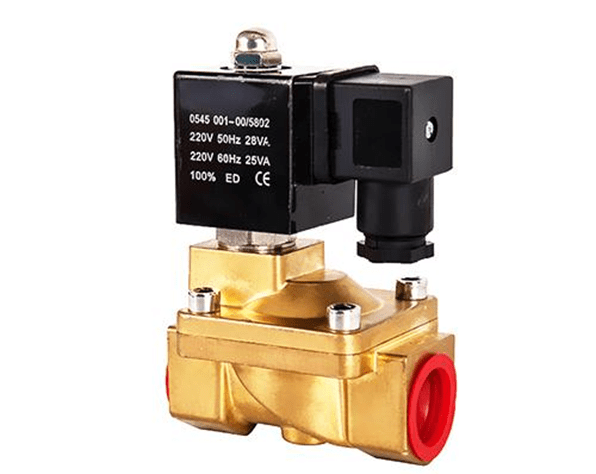

Solenoid valves are electromechanical devices that use an electric current to control the flow of fluids or gases. They consist of a solenoid coil, plunger, and valve body, with the plunger acting as the closure element.

Solenoid valves are available in various configurations, including direct-acting, pilot-operated, and 3-way/4-way valves, making them versatile for a wide range of applications, including irrigation systems, pneumatic circuits, and refrigeration systems.

3. Conclusion

The world of valves is vast and diverse, with each type offering unique features and benefits suited to specific applications. Whether it's controlling the flow of water in a plumbing system, regulating steam in an industrial process, or preventing backflow in a pipeline, selecting the right type of valve is crucial for ensuring optimal performance and system integrity.

By understanding the characteristics, operations, and applications of different types of valves, engineers and professionals can make informed decisions when choosing the most appropriate valve for their specific needs.