How to distinguish the quality of the wire?

How to distinguish the quality of the wire?

Good strong wires are the basic level of home circuit engineering, so how do consumers judge which strong wires are good wires?

The strong current part generally refers to AC 380/220V power supply lines, such as sockets, lighting, air conditioners, heaters, kitchen utensils, etc. In the home decoration process, the quality of the strong wires is very important. This point does not need to be explained too much. However, many owners, because they did not pay attention to the choice of wire, chose the wrong wire, which brought various inconveniences to life.

So, how to judge the quality of strong wires?

Commonly used wires in a house

In the home decoration process, BV lines are generally used. There are many types of wires. Commonly used wires are represented by BV, BVR, BVVB, and RVV. The differences are as follows:

How to identify BV wires

❶ Length identification

It can be said that basically all the wires on the market are less than 100 meters, and it is already considered a conscientious manufacturer to meet the requirements of more than 98 meters.

But if you want to take a ruler to measure the length, it is not only very troublesome, but also allows the store to see that you are Xiaobai at a glance. So, is there a way to calculate the length of the wire without understanding it?

Yes, the current industry-recognized measurement method has an error within 1 meter, as follows:

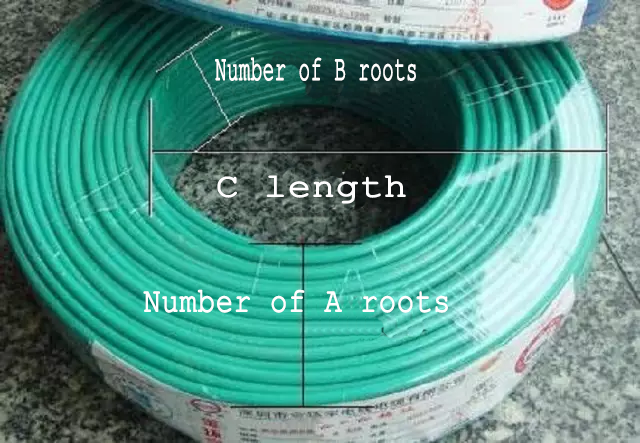

A number: the number of wires on the horizontal plane

B number: the number of wires on the vertical surface

C length: the length from any outer edge of the wire reel to the farthest inner edge of the inner reel

The calculation formula is: number of wires in meters = number of wires A × number of wires B × length of C × 3.14

For example, a wire of BV2.5, after preliminary measurement, the number of A: 12; the number of B: 16; the length of C: 16.5 cm, or 0.165 meters, based on this, the length of the wire can be calculated as: 12×16×0.165×3.14=99.47 meters.

This method is also applicable to 4 square and 6 square wires.

❷ Wire diameter identification

We often say that the 2.5 square BV wire, commonly known as copper single, refers to a wire of copper wire, that is, the cross-sectional area of the copper wire of the BV2.5 wire is 2.5 square millimeters. Then, according to the area formula of the circle, the copper wire The diameter should be about 1.78mm, which is the national standard.

How to measure? Use a micrometer or vernier caliper to:

From the figure, we can see that the diameter of the copper wire of this BV2.5 wire is 1.772mm. Because the country allows certain errors, this size is qualified by default.

Some friends said, should I bring a caliper when I buy wires? Of course not. If the seller doesn't even have a caliper, would he still dare to mix in the building materials market? Haha.

In addition, it should be specially reminded that when measuring, if you measure from both ends of the wire reel, even if the wire diameter is sufficient, it does not necessarily mean that the entire wire is of sufficient wire diameter. Because many fake and inferior products are no problem within three meters from the beginning, but after three meters, they start to become thinner, and after the last three meters, they return to their normal diameter. This is because the manufacturer is in the process of production. The copper wire is drawn. So when buying wires, many veterans will ask the boss: "Has the middle been drawn?" If the boss is afraid to say no, at this time, he must be highly vigilant.

❸ Identification of copper materials

The main cost of the wire is the metal conductor. The national standard plastic copper wire uses oxygen-free copper as the conductor, that is, oxygen-free copper (a kind of red copper). Non-standard wires will use metals with lower copper content as conductors, such as brass, galvanized copper, copper-clad copper (brass is coated with a layer of copper), or even copper-clad aluminum, copper-clad steel, etc. Electric wires have much higher resistance than copper, and when used, they will generate a lot of heat and cause accidents.

How to judge it? Generally speaking, the yellower the color, the lower the copper content. Brass is pure yellow, and copper is a bit reddish. Cut it with pliers and look at the cross section to see if the color is the same. At least it is easy to judge whether it is copper-clad aluminum or the like. Some netizens say that someone has bought a cement-like wire in the middle, which is not conductive at all. I was refreshed again:

❹ Insulator identification

First look at the thickness of the wire skin (insulator). The national standard oxygen-free copper wire 1.5-6 square wire requires a skin thickness (insulation thickness) of 0.7mm. If it is too thick, it is suspected of cutting corners, because the inner core diameter is not enough. ; And then judge the quality of the insulator, fake and inferior products, the wire skin will be easy to crack if it is pulled by hand.

❺Weight identification

Good quality wires are generally within the specified weight range. For example, the commonly used BV1.5 wire weighs 1.8-1.9kg per 100m; the BV2.5 wire weighs 3-3.1kg per 100m; the BV4.0 wire weighs 4.4-4.6kg per 100m. Poor quality wires have insufficient weight, either the length is not enough, or the copper core of the wire is too much impurity.

In addition, there are other identification methods, such as eccentricity, flame resistance, electrical resistivity, pressure resistance, high temperature impact resistance, low temperature winding performance, and acid and alkali resistance. They are more complicated and generally require instrument assistance. I’m not going to talk about it here, as ordinary consumers can only make simple judgments based on the five points mentioned above.