How to prevent the oil-free scroll air compressor from overheating in hot summer days

The high temperatures in the hot summer days are particularly prone to machine shutdowns and even spontaneous combustion. Compressed air is an indispensable part of the daily operations of many companies. Once the air compressor is shut down, it may cause great losses to the company. At the same time, if the air compressor is overheated, it needs to be repaired or replaced in time, which will also have a significant impact on production. There are many reasons for air compressor overheating, but we can take necessary measures to avoid compressor overheating.

1. Ambient temperature

The most common cause of overheating of an air compressor is its surrounding temperature and environment. For example: In the hot summer, is your air compressor placed in a location exposed to solar energy? Are there other overheated equipment next to the air compressor? Is the air compressor placed in a high ambient temperature or enclosed computer room?

These are all preventable problems. In order to prevent the air compressor from overheating, it is necessary to ensure that the ambient temperature around the air compressor is not too high. The hot summer is coming. If the air compressor is placed in a location exposed to solar energy or in a high temperature environment, it is necessary Make adjustments as soon as possible to improve the ambient temperature of the equipment room, and the ambient temperature should not exceed 40°C.

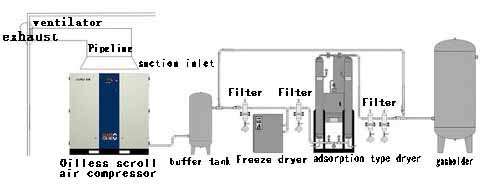

In addition to paying attention to the ambient temperature around the air compressor, it is also necessary to pay attention to the normal ventilation of the air compressor. If the chassis vent is blocked, the compressor will overheat after a long time of operation. During the installation process, it is necessary to ensure that the air compressor is installed in a suitable position, and the vents of the air compressor should be cleaned regularly to keep the air compressor case clean and well ventilated

2.Ventilation