As a speed type air compressor, centrifugal compressor can generate air flow moving in radial direction.

Centrifugal air compressors are used by a large number of companies today because of their high-pressure tightness. Therefore, common faults in the operation have become one of the most concerned issues for users.

This article will discuss causes of centrifugal compressor failures and give corresponding maintenance measures.

At the end, OKmarts has listed the problems and solutions in detail for your quick reference.

1. Common Reasons of Centrifugal Compressor Problems

1.1 Increase of Bearing Temperature

The operating temperature of centrifugal compressor bearing is generally of 45~50℃, and it should not exceed 65℃. Generally, when it is 65°C, the alarm rings, and when it’s 75°C , the device will chain stop.

Reasons for the increase of bearing temperature are as listed.

* If the clearance between the bearing shell and the journal is too small, it should be adjusted by scraping the shell.

* Small bearing lubricant inlet will lead into insufficient oil intake, so the aperture of the throttle ring should be appropriately enlarged.

* The temperature of oil is too high. Adjust the amount of cooling water in the oil cooler.

* The oil is contaminated by water, or becomes dirty and deteriorated, which will affect the lubrication effect. The oil cooler should be checked to prevent water leakage or replace the oil.

* Dirt enters the bearing and wears out the bearing shell. The bearing and lubricating oil pipeline should be cleaned, and the shell should be scrapped.

* If the bearing shell is damaged, it should be recast.

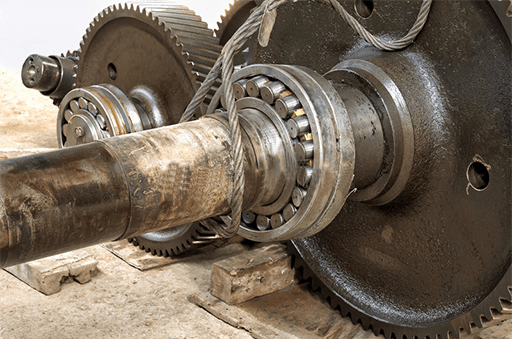

Figure 1: A close-range photograph of centrifugal compressor bearing.

1.2 Surge

Surge is a kind of abnormal vibration that occurs when the flow rate of the turbo compressor is reduced to a certain extent. Centrifugal compressor is a type of turbo compressor which will be seriously damaged by surge.

When the centrifugal compressor surges, typical phenomena include:

* The outlet pressure of the compressor rises, and then drops sharply, and fluctuates cyclically.

* The flow rate of the compressor drops sharply and fluctuates sharply. In severe cases, air may even flow back into the suction pipe.

* The current and power meter indication of the motor driving the compressor is unstable and fluctuates greatly.

* The device strongly vibrates, and at the same time it emits abnormal airflow noise.

Figure 2: A damaged centrifugal compressor caused by surge

1.3 Factors Affecting Exhaust Gas Volume

There are many factors affecting gas volume of centrifugal compressor. In addition to design, manufacturing, and installation, we will expound other factors as below.

* The air filter is clogged or the resistance increases.

At this time, the compressor suction pressure decreases. The outlet pressure remains unchanged, so the pressure ratio is increased. According to the compressor performance curve, when the pressure ratio increases, the displacement decreases.

* The air separation equipment is blocked, the resistance increases or the valve fails.

At this time, the compressor suction pressure increases. If the suction pressure remains unchanged, the pressure ratio increases, resulting in a decrease in the exhaust volume.

* Blocked intercooler or increased resistance

At this time, the exhaust volume is reduced. However, the situation of blockage in different sides is not the same.

If the air-side resistance increases, only the internal resistance of the machine will be increased, which will reduce the efficiency of compressor and the displacement. If the water-side resistance increases, the circulating cooling water will be reduced, which will lead to bad cooling of gas. Later it affects the next stage of suction, so that the compressor exhaust volume is reduced.

* Gas leakage caused by poor sealing

(1)Internal leakage:

If there is internal leakage with compressor, the compressed gas is returned and compressed twice. This will affect the working conditions of each stage, increase the pressure ratio of low-pressure stage, and decrease that of high-pressure stage. As a result, the compressor is far away from the design working condition and the displacement decreases.

(2)External leakage:

That is, air leakage from the shaft end seal to the outside of the casing.

If there is external leakage with compressor, the suction volume is constant, but part of the compressed gas leaks, causing the exhaust volume to decrease.

* Cooler leakage

If it is the first stage of leakage, the water side pressure is higher than the air side pressure, so the cooling water will enter the air side channel and be further entrained by the airflow into the impeller and diffuser.

After a certain period of time, it will cause fouling and blockage, reducing the air flow. If it is the secondary and tertiary leakage, the compressed air will leak into the cooling water and run away because the air side pressure is higher than the water side, reducing the exhaust volume.

* Frequency or voltage drop of the power

The frequency or voltage drop of the power grid will make the speed of the motor of the compressor drop, and the exhaust volume decrease.

* Increase of suction temperature and decrease of gas density

When the temperature of suction at any stage increases, the density of the gas will decrease, resulting in the suction volume to decrease.

Figure 3: The construction and working principle of centrifugal compressor

1.4 Seal Leakage

Leaks at the wheel cover seal and the inter-stage seal are all internal leakages. Severe internal leakage will increase compressor energy loss, reduce efficiency of the stage and compressor as well as gas volume.

However, the impact mechanism of the two is different too. The leakage of the wheel cover seal makes the compressed gas return to the impeller, and then performs the second stage compression. That mainly increases the total power consumption of the stage. The internal leakage of the interstage seal will increase the pressure ratio of low-pressure stage and decrease that of high-pressure stage.

Although the serious leakage of the balance disc seal has little effect on the performance of the compressor, but it affects the safe operation of compressor a lot.

The external leakage of the shaft seal is from the seal to the outside of the casing. There's no doubt that serious external leakage will directly reduce the compressor exhaust volume.

2. List of Problems and Solutions for Centrifugal Compressors

|

No. |

Problem |

Reason |

Solution |

|

I |

Abnormal Compressor Vibration |

Unit misalignment |

Re-align the unit. Eliminate the influence of external force on the pipeline. Hot inspection is required if necessary. |

|

Unbalanced rotor |

Check the curvature of the rotor and whether it is fouled or damaged. If necessary, readjust the balance of the rotor. |

||

|

Abnormal bearing |

Inspect and repair the bearing to eliminate the half-speed whirl factor. |

||

|

Coupling failure or unbalance |

Repair or replace the coupling and balance it. |

||

|

The static and dynamic parts are rubbed, the foundation sinks unevenly or the base is deformed. |

Adjust the installation gap or replace the out-of-tolerance parts, eliminate the deformation of the machine base, and strengthen the foundation. |

||

|

Unusual oil pressure and temperature |

Check the oil pressure and temperature, and working conditions of the oil system at each lubrication point. Find out the cause of the abnormality and try to solve it. |

||

|

Compressor surge |

* Inspect whether the compressor is running far away from the surge point, the anti-surge margin is correct, and the gas purity is reduced. * According to the operation manual, eliminate the surge depending on the reasons. |

||

|

Gas brings liquid or impurity exists. |

Eliminate spare liquid and impurity. |

||

|

Excessive mechanical and electrical runout of the vibration measuring part of the journal |

Eliminate the mechanical and electromagnetic deviation of the shaft neck position. |

||

|

Thermal-caused bending of rotor |

Repair or replace the rotor. |

||

|

The rotor is cracked. |

Repair or replace the rotor. |

||

|

II |

Unusual Vibration of Compressor Pipeline |

Excessive piping stress |

Remove the piping stress. |

|

Air flow excitation |

Adjust process parameters. |

||

|

Improper design of pipeline support |

Re-check it. |

||

|

III |

Excessive Axial Thrust and Increasing Shaft Displacement |

The inter-stage seal is damaged or worn, causing the seal gap to increase. |

Replace the seal. |

|

Gear or diaphragm coupling tooth surface is worn. |

Repair or replace the coupling and other parts. |

||

|

Compressor surge or unstable air flow |

Adjust the process parameters to make the compressor run stably. |

||

|

Thrust end face runout of the thrust disc and seriously deformed bearing seat |

Replace the thrust disc or bearing seat |

||

|

Incorrect zero position of shaft displacement probe and poor probe characteristics |

Check the probe and re-calibrate the zero position of the probe. |

||

|

Fluctuation of oil temperature and pressure |

Adjust it accordingly. |

||

|

Thrust bearing is damaged. |

Replace the thrust bearing. |

||

|

IV |

Rising Compressor Bearing Temperature |

Improper installation of thermometer or damaged thermocouple |

* Examine the installation of the temperature measuring sleeve. * Calibrate the thermometer, replace or repair the thermocouple and other temperature measuring components. |

|

The oil supply temperature is high or the oil quality does not meet the requirements. |

Check the pressure and flow of the cooling water. Use the spare cooler or replace with new oil. |

||

|

Reduced amount of lubricating oil or low oil pressure |

* Examine the oil viscosity, water content and demulsibility, etc. * Check the oil level of the oil tank and the working condition of the pump. * Examine the pressure difference of lubricating oil filter, use the spare filter or clean it. * Check the valve opening degree and oil leakage of the oil system. |

||

|

Bearing damage |

Repair or replace the bearing. |

||

|

Increased axial thrust or improper assembly of thrust bearing |

* Inspect the compressor rotor and sealing conditions. * Adjust the gap, examine the thrust bearing, eliminate defects and the phenomenon of compressed gas bring liquid. |

||

|

Compressor air seal leaks |

Adjust the air seal gap or replace the air seal. |

||

|

V |

Compressor Radial Bearing Failure |

Unusual lubrication |

Lubricant must be qualified. |

|

Compressor misalignment |

Check the alignment and adjust it if necessary. |

||

|

Incorrect bearing clearance |

Inspect the clearance, adjust or replace the bearing if necessary. |

||

|

Unbalance of compressor or coupling |

Examine the rotor assembly and coupling to see if there is dirt attached or rotor missing. If necessary, re-balance the rotor. |

||

|

VI |

Compressor Thrust Bearing Failure |

Excessive axial thrust |

* Check the thrust bearing clearance. * Examine the gas inlet and outlet pressure difference. If necessary, check whether the internal sealing ring gap data exceeds the standard. * Inspect if the gap of the balance disc seal ring between the segments exceeds the standard. |

|

Abnormal lubrication |

Check the following items: * Oil pump, filter and cooler * Oil temperature, pressure and quantity. * Quality of the oil |

||

|

VII |

Compressor Surge |

The operating point falls into the surge zone or is too close to the surge boundary. |

* Examine the position of the operating point on the compressor characteristic line. * If it is close to the surge boundary or falls into the surge zone, the operating conditions should be adjusted. |

|

Improper setting of anti-surge margin |

Change the setting value of the automatic control system. |

||

|

Insufficient suction flow |

* Check the opening degree of the intake valve and eliminate the blockage of the passage. Put in anti-surge automatic control. * Stop the compressor when the flow is too low. |

||

|

Compressor outlet pressure is too high. |

* When the compressor is decelerated and stopped, the gas is not vented or returned. * The outlet check valve is malfunctioning or not tight, and the gas is backfilled. Identify the causes. |

||

|

When the working conditions change, the vent valve and the return valve are not opened in time. |

When the inlet flow decreases or the speed changes, the anti-surge vent valve or return valve should be opened in time. |

||

|

The anti-surge device is not turned on automatically. |

The anti-surge device should be turned on automatically during normal operation. |

||

|

Inaccurate or malfunction of anti-surge device or mechanism |

* Regularly examine the working condition of the anti-surge device. * If it is out of order, inaccurate or jammed, or delayed in action, solve the problem at once. |

||

|

Increase the speed and pressure too fast. |

Slowly and evenly increase the speed and pressure. |

||

|

Decrease speed without lowering the pressure |

The pressure should be lowered before the speed is decreased. |

||

|

Serious changes in gas properties or state |

Adjust the process parameters within the scope of design requirements. |

||

|

Interstage leakage increases |

Replace the interstage seal. |

||

|

The molecular weight of the gas changes. |

Modify the mixed gas ratio to the required range. |

||

|

VIII |

Compressor Shaft End and Sealing Surface Leakage |

Damaged shaft end comb air seal |

Repair or replace the comb air seal. |

|

Damaged sealing ring of the cylinder body |

Replace the sealing ring. |

||

|

Excessive oil pressure |

Adjust the oil pressure to the required range. |

||

|

Damaged oil seal |

Replace the oil seal. |

||

|

Increased leakage in the compressor |

Replace or repair the interstage gas seal. |

||

|

Insufficient sealing ring accuracy |

Check the sealing ring, repair or replace it if necessary. |

||

|

Sealing oil quality and oil temperature do not meet the requirements. |

Examine the quality of sealing oil and replace it if the index is not consistent. Check and adjust the temperature of sealing oil. |

||

|

The oil and gas pressure differential system is not working well. |

Check the sealing gas pressure and circuit, and adjust to the specified value. Inspect the working condition of each component in the differential pressure system. |

||

|

Worn or damaged seal |

Remove the seal and then adjust the clearance. Repair or replace it according with requirement. |

||

|

The end surface of the floating ring seat is notched or worn. |

Avoid damage, reduce wear, and replace new parts if necessary. |

||

|

The floating ring seat is worn unevenly. |

Grind, correct the contact surface or replace with new spare parts. |

||

|

Broken or damaged sealing ring |

* It may be damaged during assembly. Pay attention to the assembly. * Non-load operation should be avoided as far as possible. It should be replaced when it cannot be repaired. |

||

|

The sealing surface, seals, and O-rings are corroded. |

* Analyze the nature of the gas. * Change the material of the parts or replace with new ones. |

||

|

The sealing part freezes due to the operation of the low temperature part. |

Eliminate icing, or clean and seal the atmosphere with dry nitrogen. |

||

|

Working error of measuring instrument |

Check the measuring instruments of the system and repair or replace them if they are found to be inaccurate. |

||

|

IX |

Leakage of Inlet and Outlet Flanges |

Damaged inlet flange pad |

Replace the pad. |

|

Damaged outlet flange pad |

Replace the pad. |

||

|

Worn inlet sealing surface |

Repair the sealing surface. |

||

|

Worn outlet sealing surface |

Repair the sealing surface. |

||

|

Excessive inlet piping stress, flange deformation |

Eliminate piping stress. |

||

|

Excessive outlet piping stress, flange deformation |

Eliminate piping stress. |

||

|

X |

Oil Seal Leaks |

Oil seal clearance exceeds standard |

Replace the oil seal. |

|

Blocked oil return hole of oil seal |

Unblock the oil return hole. |

||

|

Worn oil seal comb |

Repair the sealing part or change the axial sealing position. |

||

|

The upper and lower oil seals are not concentric |

Reassemble the oil seal. |

||

|

Incorrect assembly |

Reassemble it in the correct way. |

||

|

Excessive oil pressure |

Other operations |

||

|

Misalignment and vibration |

Eliminate |

||

|

Operation failure of oil exhaust fan |

Check the operation of the oil exhaust fan and clean the filter element of the oil mist separator |

||

|

XI |

Motor Overload |

Electrical problem |

Examine the operation of the circuit breaker; check whether the voltage is reduced and whether the current difference of each phase is within 3%. |

|

The surface of the diffuser adjacent to the impeller is corroded and the degree of diffusion is reduced. |

Check flow channels of the diffuser. If there is corrosion, improve the material or increase the surface hardness. Clean the surface to make the surface smooth. If the impeller and the diffuser collide or the diffuser is deformed, repair or replace it as appropriate. |

||

|

Deformation of impeller or diffuser |

Repair or replace them. |

||

|

The rotating part collides with the stationary part |

Examine the gap of each part. If it does not meet the requirements, it must be adjusted and replaced. |

||

|

High suction pressure |

Compare with design data, find out the problem, and solve it. |

||

|

XII |

Lubricant Discoloration |

Lubricating oil emulsification |

Change the lubricating oil |

|

Oil temperature is too high |

* Strengthen the cooling effect. * Improve lubrication methods. * The assembly clearance of the oil pump is incorrect. |

||

|

Excessive mechanical impurities |

* Replace lubricating oil. * Check the bearing system and replace worn parts. |

||

|

Wrong lubricating oil |

Change the lubricating oil. |

||

|

XIII |

Abnormal Lubricating Oil Pressure |

Leakage at the connection |

Eliminate the leakage. |

|

Damaged pressure regulator |

Replace the pressure regulator. |

||

|

The oil pump fails to raise pressure. |

Repair the oil pump. |

||

|

Oil filter is blocked. |

Replace or clean the oil filter. |

||

|

Inaccurate pressure gauge display |

Replace the pressure gauge. |

||

|

Poor oil return |

Check and unblock the oil return pipeline. |

||

|

Facet leakage in the bearing seat |

Eliminate the leakage. |

||

|

XIV |

Compressor Coupling Failure |

Damaged diaphragm |

Replace the diaphragm. |

|

Loose and worn connecting bolts |

Fasten the connection or replace it. |

||

|

Coupling guard collision |

Adjust the guard position. |

||

|

Lubricating oil has deteriorated or become less |

Replace or add it. |

||

|

Coupling guard collision |

Adjust the guard position. |

||

|

Oil leakage in the cover of the coupling guard |

Repaint the sealant or replace the sealing strip. |

||

|

XV |

Interstage Cooler Leakage |

Corrosive and worn cooler |

Check the cooling water quality to see if it is contaminated and if inappropriate water is used. |

|

Broken cooler |

* Examine whether the tube is securely fixed, whether the fixed part is damaged. Replace it in time. * Check if the cooling water pressure is within the design range and adjust it in time. |

||

|

Improper installation |

* Inspect whether the inner tube is tight. * Check if the flange surface is flat and the connection is normal. * Examine whether the gasket material is qualified. If it is broken, replace it in time. |