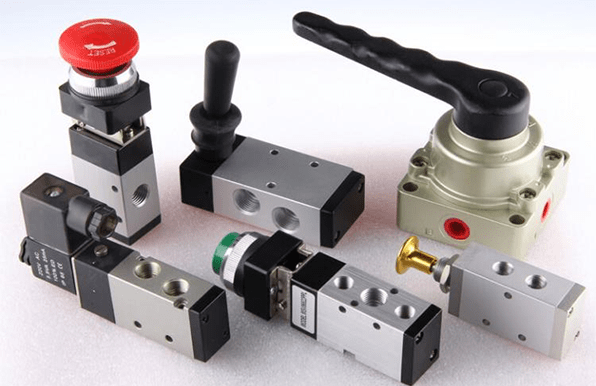

Figure 1: Directional control valves of different models.

Hydraulic solenoid valves are used to control the flow direction or adjust the flow and pressure of liquids (oil, water, or air) in hydraulic systems. As a type of hydraulic valve, the directional control valve uses the change of the flow path to control the flow direction of the oil.

The main function of the spring in the check valve is to help the valve close quickly when there is no oil flow through or backflow of oil. But it also increases the resistance when the valve opens and becomes the main part of the pressure loss when the oil flows through the check valve. The spring should be made softer without affecting the sensitivity and reliability of the valve. Generally, the opening pressure of the check valve is 0.035-0.05MPa, and the pressure loss when the whole flow passes through is about 0.1-0.3MPa.

The types of directional control valves include check valve, hydraulic control check valve, reversing valve, deceleration valve, prefill valve, shuttle valve, etc. According to its use, it can be divided into two categories: check valve and reversing valve.

Since directional control valves can be further divided into plenty of subcategories, each of which has their own characteristics, structures and working principles, the following will introduce them in terms of their different classifications.

1. Check Valves

Figure 2: A check valve in sectional view.

A check valve, also known as non-return valve or one-way valve, functions to make the fluid to flow in only one way.

According to the different spool structures, check valves can be divided into two types: ball valve and poppet valve. The ball valve spool has a simple structure, but is very likely to have poor sealing due to friction, and is only used in low pressure conditions. The poppet valve type has more applications and better sealing performance.

According to the channel in the valve, it can be divided into straight-through type and right-angle type. The resistance of liquid flow in straight-through valve is small, and the replacement of the spring is also more convenient. It is generally connected by pipes. The right-angle type can be connected by pipes, plates or flanges.

2. Reversing Valves

The main difference between a check valve and a reversing valve is that the check valve only controls the opening and closing of the oil circuit, and does not change the direction. The reversing valve, in contrast, can change the flow direction of the liquid through the movement of the spool, thereby controlling the working direction of the actuator.

The function of the reversing valve is to use the relative movement of the spool and the valve body to connect, close the oil circuit or change the flow direction of the oil to the actuator, so that the actuator can start, stop or change the direction of movement.

According to the structure, the reversing valve can be divided into rotary valve type and slide valve type. According to the number of working positions of the spool, there are two-position, three-position and multi-position, etc. According to the number of inlet and outlet channels, there are two-way, three-way, four-way and five-way pass and so on. According to the operation and control methods, it is divided into manual, motorized, electric, hydraulic and electro-hydraulic valves. According to the installation method, there are pipe, plate and flange connections.

The following is a brief introduction to the two types of reversing valves. They are classified in terms of the structures and "position" and "way".

2.1 According to the Structures

(1) Rotary Control Valves

The rotary control valve changes the flow direction of the oil by using the rotation of the valve core relative to the valve body. The rotary valve has poor sealing performance and unbalanced radial force, so it is generally used in low-pressure, small-flow systems.

(2) Slide Control Valves

The slide control valve changes the flow direction of the oil by using the axial displacement of the valve core relative to the valve body. The reversing valve changes the left and right positions, i.e., the direction of movement of the actuator.

2.2 According to Positions and Ways

Figure 3: Directional control valve of different numbers of positions and ways.

Positions: the number of working positions that the valve stays relative to the valve body.

Ways: the number of the ports connecting the valve to the main oil circuit.

Related Info

Tips for Solenoid Coil WindingHow to Improve the Quality Factor of the Solenoid Coil?

What is a Color Coded Inductor Coil?

What is a Refrigeration Solenoid Valve?

5 Refrigeration Solenoid Valve Failures and the Solutions