- a

- b

- c

- d

- e

- f

- g

- h

- i

- j

- k

- l

- m

- n

- o

- p

- q

- r

- s

- t

- u

- v

- w

- x

- y

- z

- 3

- 7

Peristaltic Pump

Hose pumps belong to the category of peristaltic pumps. The peristaltic pump is a type of rotor-type volumetric pump, named for its working principle similar to the digestive tract to transport gas, solid and liquid three-phase media in a peristaltic manner.

Designers and users of hose pumps are primarily concerned with their ability to handle highly abrasive media. It has no valve, no seal, the only part in contact with the medium is the inner cavity of the rubber hose, and the rotor of the compression hose is completely independent of the medium.The uniqueness of the hose pump: No other pump has better self-priming ability than the hose pump, which can almost generate a perfect vacuum to suck liquid; transport gas-containing liquid and foam liquid without air resistance; transport high-viscosity, Shear-sensitive media are also strong points; fixed displacement per revolution independent of outlet pressure, inherently metering pumps.

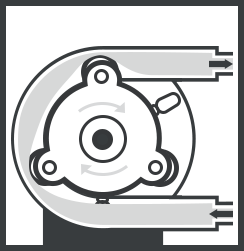

Peristaltic Pump Working Principle

The peristaltic pump working principle depends on transporting a product throughout a hose, by reducing and increasing. The pump shoes can be connected onto the rotor of the pump to push the liquid throughout the pump. The principle is related to how the human body supplies blood, oxygen, and nutrition.

Peristaltic Pump is great for clean with hygienic where pollution with exposed pump mechanism cannot happen. These are significant pumps while isolating a liquid from the atmosphere, as well as the atmosphere from the liquid. These pumps can be found in an extensive range of industrial applications where harsh & viscous fluids are used.

Types of Peristaltic Pump

The peristaltic pumps are classified into two types namely hose pumps as well as tube pumps.

Hose pumps

The hose pumps are ideal for supplying extremely hard content.

Higher pressure peristaltic hose pumps which can typically operate against up to 16 bar (230 psi) in continuous service, use shoes (rollers only used on low-pressure types) and have casings filled with lubricant to prevent abrasion of the exterior of the pump tube and to aid in the dissipation of heat, and use reinforced tubes, often called "hoses". This class of pump is often called a "hose pump".

The biggest advantage with the hose pumps over the roller pumps is the high operating pressure of up to 16 bar. With rollers, max pressure can arrive up to 12 bar (170 psi) without any problem. If the high operating pressure is not required, a tubing pump is a better option than a hose pump if the pumped medium is not abrasive.

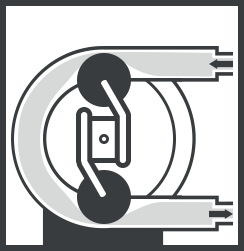

Tube pumps

Tube pumps are ideal for low supply rates, and these are completely programmable with the choice of numerous heads.

Lower pressure peristaltic pumps typically have dry casings and use rollers along with non-reinforced, extruded tubing. This class of pump is sometimes called a "tube pump" or "tubing pump". These pumps employ rollers to squeeze the tube. Except for the 360° eccentric pump design as described below, these pumps have a minimum of 2 rollers 180° apart and may have as many as 8, or even 12 rollers. Increasing the number of rollers increases the pressure pulse frequency of the pumped fluid at the outlet, thereby decreasing the amplitude of pulsing. The downside to increasing the number of rollers it that it proportionately increases the number of squeezes, or occlusions, on the tubing for a given cumulative flow through that tube, thereby reducing the tubing life.

Features of Peristaltic Pump

These pumps offer excellent pumping solutions, particularly whenever the product being pushed is mainly rough, acidic otherwise thick. These are inexpensive for maintaining because of the lack of seals, valves, & glands but the only maintenance thing is the tube otherwise hose. These pumps are also having a moderate pumping act, perfect for shear responsive polymers & delicate cell cultures. Finally, the only element of the pump is in contact through the liquid being pumped inside of the pump otherwise hose. Assembling and purifying of surfaces in the pump is simple.

Design is seal-less

Low protection costs

Self-priming & dry running

Gentle pushing act

High suction pick up

Scratch resistant

Solids managing

ReversibleNo fall

Precise dosing

Clean

Applications of Peristaltic Pumps

The applications of these pumps include in a different range of areas wherever liquids are required to flow within fresh as well as germ-free circumstances. The applications mainly include in daily applications also.

Infusion pumps

Analytical chemistry testing

Aquariums

Pharmaceutical production

Open heart bypass pump equipment

Auto Analyzers

Beverage supply equipment

Exclusion of dirt

Decorative waterfalls & fountains

Industrial dishwasher clean aid machines

Dialysis equipment

Carbon Monoxide observers

Food manufacturing

Chemical handling

Water & Wastewater

Engineering & manufacturing

Peristaltic pumps, due to their design, are ideal for all applications where the fluid needs to be dosed with precision and any possibility of contamination must be excluded, such as for food, medical, and analytical applications.In the medical field, peristaltic pumps are perfect thanks to their compatibility with fluids of different natures and viscosities. Thus, when using corrosive or chemical liquids, the risks of leakage or damage to the pump are limited. On the contrary, resorting to the peristaltic principle, it is possible to obtain excellent results in this field.Thanks to the precision and complete separation between the liquid and the pump, peristaltic pumps find widespread use even in those fields that operate in close contact with inks, enamels, glues, and paints.For water treatment-related applications, peristaltic pumps are useful because they're suitable not only with chemical substances used in these treatments but also with liquids that are dense or contain suspended solids, without any risk of damage.

Finally, the food and beverage field also resorts to the peristaltic principle of these pumps for product pumping, transferring, and dosing purposes (such as with several beverages).