Video: Air-Cooled Chiller Cooling Fan Problems and Solutions

Figure 1: Air cooled chiller units.

Air-cooled chillers are one of the very important equipment in modern life, which is widely used in industrial,

commercial and domestic environments to reduce and control temperatures in production and life. The cooling fan is one of the important components of a chiller. If there is a problem with the fan, it

will affect the effective operation of the system.

First, let's understand the role of a chiller fan. The chiller removes heat by circulating coolant fluid to achieve

cooling effect. The fan plays a key role in this process. It blows air across the surface of the chiller condenser,

taking away heat and improving the cooling effect of the system. Therefore, if the fan is not running, the chiller

cannot cool down effectively.

1. Air-Cooled Chiller Fan Not Spinning: Reasons and Solutions

Sometimes you may encounter the problem of the chiller fan not running, which may affect the normal operation of the chiller. The following will discuss ways to fix the chiller fan not running.

1.1 Check Power Supply and Wire Connections

If the chiller fan is not running, the first thing you should check is that the power supply and wiring connections are normal. Make sure the chiller is properly connected to the electrical outlet and there are no broken or damaged wires. If there are any problems, the wires should be repaired or replaced, and make sure the plug is tightly connected to the outlet.

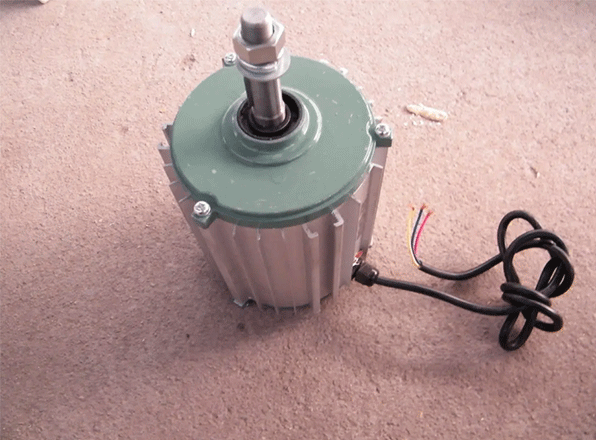

Figure 2: Chiller fan.

1.2 Check Control Panel

The control panel may be malfunctioning, preventing the fan from starting properly. In this case, control panel inspection and repair is required.

1.3 Clean the Fan

The fan may not be able to spin freely due to accumulation of dust and dirt. Clean the fan regularly, using a soft brush or hair dryer to remove dust and dirt. Make sure to disconnect the power supply during the cleaning process and wait for the fan to dry completely before reconnecting power.

1.4 Check Controls and Switches

The chiller's controls and switches may become damaged or fail, preventing the fan from working. Check the operating condition of controls and switches and repair or replace them if necessary. Make sure controls and switches are set up correctly and operate properly.

1.5 Check the Motor

Motor overheating may cause damage to motor components

and prevent the fan from working properly. At this time, you need to check whether the motor is overheated. If so,

you need to stop it to cool down and replace the damaged parts.

If the chiller has been used for a long time, the motor components may have aged excessively, causing the fan to

fail to work properly. At this time, the motor parts or the entire motor need to be replaced.

Figure 3: Chiller fan motor.

1.6 Check for Drive System Problems

A loose or broken drive belt can cause the fan to run sluggish or not (if the fan is driven by a belt). It is

necessary to check whether the belt is loose or damaged, and if any problem is found, it needs to be replaced in

time.

Damaged drive bearings may also prevent the fan from running. This problem requires replacement or repair.

1.7 Air Duct Blocked

Blockage of the air duct may also cause the fan to fail to operate normally. It is necessary to check whether the air duct is blocked and clear it in time.

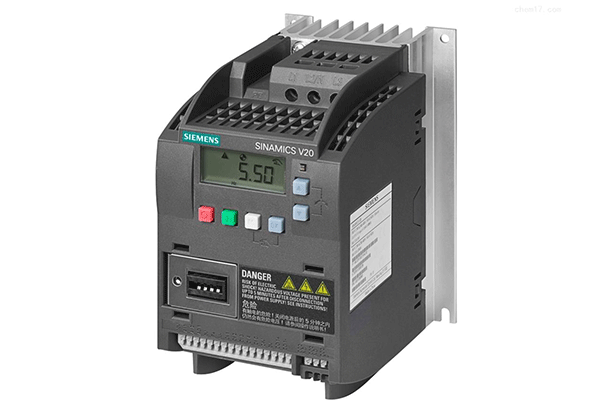

1.8 Frequency Converter Debugging Issues

If the chiller uses an inverter for speed regulation, there may

also be a problem with the inverter setting that causes the fan motor to fail to start or the speed is too slow. At

this time, the frequency converter needs to be debugged.

A component or circuit failure inside the chiller requires experienced technicians to repair it. In this case, it is

recommended to seek professional help.

Figure 4: Frequency converter.

2. Air-Cooled Chiller Fan Noise: Causes and Solutions

Air-cooled chillers are common cooling equipment, but sometimes fan noise occurs during use, which troubles many users.

2.1 Wear of Fan Bearings

The main cause of fan noise is the wear of fan bearings. The fan bearing is a component that connects the fan blades

and the motor. Its function is to provide friction so that the fan blades can rotate.

However, due to long-term operation and environmental influences, fan bearings will suffer from wear, aging,

deformation and other problems, resulting in unstable fan rotation and noise.

Lubricate the fan bearings. Lubrication reduces friction in the fan bearings, allowing them to run more smoothly,

thereby reducing noise.

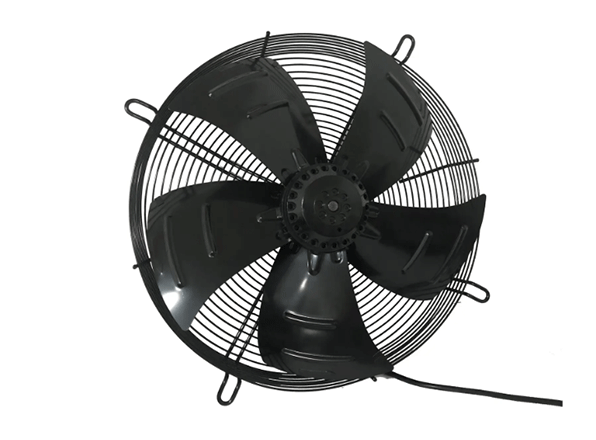

2.2 Imbalance of Fan Blades

In addition, the imbalance of fan blades is also an important factor in fan noise. The fan blades must be balanced

when rotating, otherwise the blades will rub against the casing or support rods, causing noise.

The reason for the imbalance of the fan blades may be that dust, bacteria and other impurities are adhered to the

blades, or the blades are damaged and need to be cleaned and replaced in time.

Clean and replace the fan blades. Cleaning can prevent the blades from becoming unbalanced due to adhering

impurities, and replacement can solve the problem of blade damage.

Figure 5: Chiller fan blades.

2.3 Fan Motor Failure

In addition, motor failure may also cause fan noise. The motor is a key component that drives the fan to rotate. If

there is a problem with the motor, such as winding short circuit, rotor eccentricity, etc., it will affect the

operation of the entire fan and produce noise.

If the noise is caused by motor failure, corresponding maintenance measures need to be taken.

In addition to the above common causes, fan noise may also be related to other factors. For example, excessive

temperature, loose fan blades, deformation of the chassis, etc. may lead to fan noise. Therefore, when

troubleshooting fan noise problems, it is necessary to comprehensively consider various factors and investigate one

by one.

3. Noisy Air-Cooled Screw Chiller Fan: Reasons and Solutions

Since the air-cooled screw chiller uses a fan to dissipate heat, its installation and use environment must be in an

open area with good air circulation, which will help improve the working efficiency of the chiller. The fan of the

air-cooled screw chiller is installed on the top. Some customers choose to install it on the side of the chiller if

they have special needs.

Causes and solutions for excessive fan noise in air-cooled screw chillers:

1. Too Fast Rotation Speed: After reducing the rotation speed, check whether the fan noise is still loud. If the

noise is still too loud, you can only replace the fan with a new one.

2. Large Gaps and Worn Parts: Adjust the gap to the appropriate position. Worn parts cannot be repaired and can only

be replaced with new parts.

3. Motor Problems: Check whether there are problems with the motor and power supply, and solve them as soon as

possible.

4. Lubricating Oil: If there is too little lubricating oil, just fill the lubricating oil to the required position.

If there is a lubricating oil quality problem, replace it with regular and qualified lubricating oil.

5. Bearing Fracture: Contact the chiller manufacturer to replace the bearing with a new one.

7. Clogged Fan: Check the air inlet and outlet and clear the blockage.

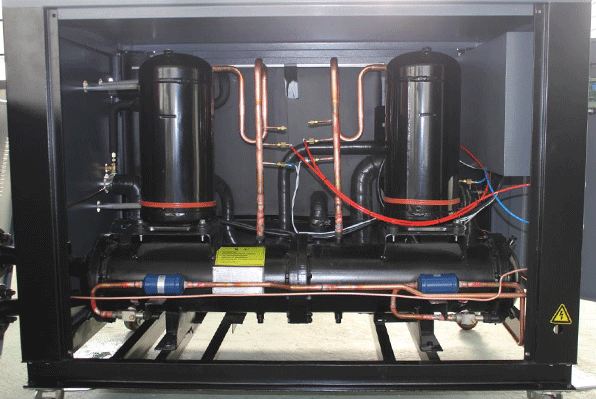

Figure 6: Screw chiller unit.

4. How to Effectively Improve the Cooling Efficiency of Air-Cooled Chillers?

When an air-cooled chiller is operating stably, the environment factor has the greatest impact on its heat

dissipation efficiency. First, the chiller working environment must be with smooth ventilation, and then keep the

machine room clean and tidy. After all, air-cooled chillers mainly rely on electronic fans to dissipate a large

amount of heat through fins.

If there is a lot of dust in the environment, they will adhere to the fan and fins. When the dust on the fins

continues to increase, it will directly affect the cooling effect of the air-cooled chiller, causing the cooling

capacity of the air-cooled chiller to become worse, the energy consumed by the chiller to continue to increase, and

seriously affecting the normal use of the air-cooled chiller.

You can use the following methods to avoid the low cooling effect of fins / fans:

4.1 Provide a Clean Usage Environment

First of all, you should provide a clean environment for air-cooled chillers. A clean usage environment can ensure that the air-cooled chiller is kept away from the hazards of various dusts. Even if you use the air-cooled chiller equipment for a long time, you will not encounter low operating efficiency of the air-cooled chiller due to the dust in the environment.

Figure 7: The inner structure of an air-cooled industrial chiller.

4.2 Clean Regularly

Secondly, the room where the chiller is installed should be cleaned regularly. To keep the environment suitable for

the operation of an air-cooled chiller, after using the air-cooled chiller for a period of time, the environment and

machinery and equipment need to be comprehensively cleaned. Clean most of the dust and oil stains to keep the

environment clean.

Operating air-cooled chiller equipment in a clean and tidy environment can effectively reduce the probability of

air-cooled chiller failure, and improve the safety of enterprises using air-cooled chillers.

5. Conclusion

Chillers are important cooling equipment, and correct maintenance and timely repair of faults are crucial to their long-term normal operation. As a high-quality refrigeration equipment parts supplier, O&Kmarts recommends that users regularly inspect and maintain equipment during use to ensure efficient operation of the equipment, thereby reducing the occurrence of problems.