Video: Cooling Methods for DC Charging Piles and Selection of Cooling Fans

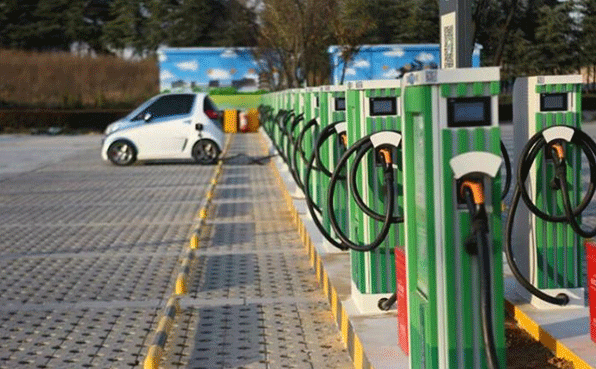

Figure 1: Charging piles.

Compared to other power sources, charging stations (charging piles) have much greater heat dissipation requirements,

making the thermal design of the system extremely strict. The power range of DC charging piles is 30KW, 60KW and

120KW, with efficiency generally around 95%. This means that about 5% of the power is converted into heat loss,

which amounts to 1.5KW, 3KW, and 6KW, respectively. This heat must be discharged from the equipment, otherwise it

will accelerate the aging of the equipment.

Since the harsh operating environment of charging piles, the industry has been continuously seeking breakthroughs in

cooling methods. Four cooling methods, including forced air cooling, independent air duct, liquid cooling, and

natural cooling (mainly relying on heat sinks), are used in different types of DC charging piles.

Due to factors such as volume, cost, reliability, etc., most companies currently use forced air cooling.

1. 4 Cooling Methods for DC Charging Piles

1.1 Forced Air Cooling

Forced air cooling refers to a cooling method that circulates air using a fan. The fan blows or draws air directly against the "heat source

devices" (such as MOS tubes, transformers, inductors, electrolytic capacitors, etc.), and takes away the heat

through forced ventilation. For heat source devices such as MOS tubes, they need to be placed close to the heat sink

to disperse their heat, as they are small in size and heat accumulates rapidly.

Forced air cooling is the most common cooling method used for indoor switch-mode power supply products, such as

server computers and desktop computer power supplies. Compared with natural cooling, forced air cooling dissipates

heat faster and more efficiently.

However, it has its drawbacks, including: low protection level (bringing dust, corrosive gas, moisture, etc.) and

high noise.

In the forced air cooling method, a particular design involves using both a forced air fan and a heat pipe for

cooling. This design method is particularly common in high-power electronic products (such as notebook computers,

high-performance desktop computers, etc.). The use of heat pipes can solve the heat dissipation problem without

adding too much space, and at the same time does not affect product performance and appearance. However, this

cooling method has not been applied in the field of charging modules.

Figure 2: Charging pile cooling fan from ebmpapst.com.

1.2 Independent Air Duct

The independent air duct means completely sealing the PCBA (Printed Circuit Board Assembly), and the heat generated

by heat source components is conducted to the fins of the heat sink through conduction. The fan can take away the

heat generated by the sealed part just by blowing air onto or drawing air away from the heat sink fins.

Using this cooling method, the heat is evenly dispersed across the large-area heat sink. At normal temperature, the

fan can dissipate the heat at a very low speed (4000 rpm), so the noise can be very small. The noise at normal

temperature can be controlled within 45 decibels.

Since the PCBA is sealed, IP6X "dust-free" is guaranteed. Low noise and high protection are the two major advantages

of independent air duct design.

Figure 3: Charging station.

1.3 Liquid Cooling

A complete liquid cooling system includes a water pump, water tank, fluid, radiator, fan, etc.

The PCBA process of the liquid cooling method is similar to that of the independent air duct. It involves completely

sealing the PCBA by sealing the entire die-cast body with grooves and gaskets. The difference is that in liquid

cooling, the heat conducted to the die-cast body is then carried away by the flow of liquid through internal water

channels.

Underneath the PCBA, there is an embedded water channel, with a water inlet and outlet. The heat is carried away by

the flow of the liquid, but how is it ultimately dissipated? The heat ultimately has to be dispersed by the radiator

and taken away by the pressure difference created by the fan.

Figure 4: Charging piles near the residence zone.

1.4 Natural Cooling

Natural cooling is a cooling method that uses the high thermal conductivity of metal materials to take away heat and

dissipate heat into the air. It relies on natural convection between exhaust and intake vents to achieve cooling. In

cases where there are no specific airflow speed requirements, natural convection is employed, and the heat sinks

used are copper-aluminum sheets, aluminum extrusions, heat pipes, machined or alloy castings.

Since natural cooling mainly utilizes natural airflow, the area and layout of heat dissipation need to be planned in

advance during product design, otherwise it will lead to insufficient or uneven heat dissipation.

The amount of heat that can be taken away by natural cooling is limited. In order to take away more heat, the heat

sink must be larger and, accordingly, heavier.

2. What to Consider When Choosing a Cooling Fan for a EV Charging Pile?

Figure 5: Open-air charging piles.

The faster the charging rate, the higher the output power of the charging pile inductor module and the greater the

charging current, which means the greater the heat caused by the inductor module, power module and other components.

Charging pile cooling fans are designed to keep the operating temperature of the charging pile stable and are

usually installed inside or outside the charging pile. When purchasing a charging pile cooling fan, the following

aspects should be payed attention to:

1. Cooling Effect: Choose a fan with good cooling effect, preferably an axial flow fan with high air volume and high

air pressure, to ensure that the charging pile can maintain a stable temperature during long-term high-load

operation.

2. Noise Level: Charging piles are usually installed in public places or residential areas, so fans with low noise

levels should be selected to avoid disturbing residents.

3. Current and Voltage: Choose a fan that meets the current and voltage requirements of the charging pile to avoid

having a negative impact on the charging pile.

4. Durability: Choose a fan with good durability, preferably from a reputable axial flow fan brand, to ensure

long-term stable operation.

5. Installation Method: According to the specific conditions of the charging pile, choose the appropriate

installation method, which can be built-in or plug-in, so as to better adapt to the needs of different scenarios.

6. Waterproof: Charging pile sites are generally outdoors, and the cooling fans must be moisture-proof,

anti-fouling, and anti-corrosion, so choose waterproof cooling fans.

In short, choosing a suitable charging pile cooling fan requires consideration of many aspects, including cooling

effect, noise, current and voltage, durability, etc. It is recommended to understand the features and user reviews

of different brands and models before purchasing to make a more informed choice.