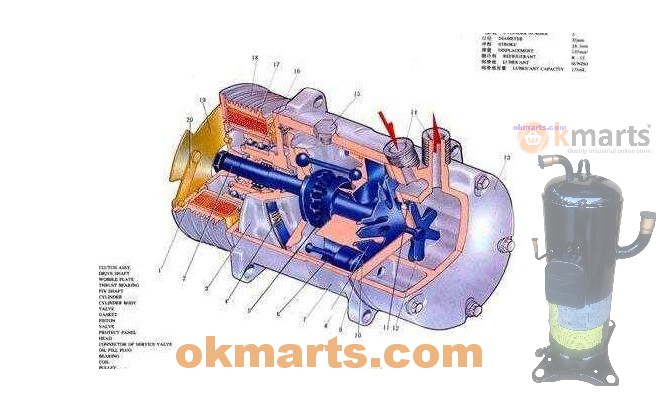

Analysis of common faults and solutions of air-conditioning compressors The air conditioning compressor is the heart of the refrigeration system and the power source for the refrigerant to circulate in the system. The basic working principle of the refrigeration system mainly includes the four processes of compression, condensation, throttling and evaporation. The compressor compresses the low-temperature and low-pressure refrigerant into a high-temperature and high-pressure gas refrigerant, turns the refrigerant into a medium-temperature and high-pressure liquid refrigerant through a condenser, then turns into a low-temperature and low-pressure liquid refrigerant through a throttle expansion device, and finally turns into a low temperature through an evaporator Low-pressure gas refrigerant. After evaporating and absorbing a large amount of surrounding heat, low-temperature and low-pressure refrigerant is sucked into the air-conditioning compressor for the next refrigeration cycle to achieve the cooling effect

Common failure phenomena of air conditioner compressor 1. The winding short circuit, open circuit and winding touch the chassis ground: this type of fault is caused by the motor part of the compressor. The power supply is normal when the circuit is open, and the compressor does not work; the protector acts after the short circuit and the shell are energized, or burn Fuse; if there is a slight short circuit between the turns of the winding, the compressor can still work, but the temperature of the compressor is very high, the working current is very large, and the thermal protector will act shortly after working. Generally, a multimeter can be used to check that the winding is open and the winding touches the chassis ground; the winding is slightly short-circuited and it is not easy to judge, and it should be judged according to the measured current. 2. Vibration and noise of the compressor: This situation often occurs during maintenance. Generally, the cooling performance is not much affected, but the user feels abnormal, mainly due to the collision between the pipe and the casing, the shock-absorbing block falling off, and the compressor fixing Loose bolts, etc. 3. The compressor suction and exhaust valves are not closed tightly: if the compressor suction and exhaust valves are damaged, even if the refrigerant is sufficient, the system cannot establish high or low pressure or it is difficult to establish a qualified high and low pressure, the system is not cooled or the cooling effect is very poor . 4. Compressor holding shaft and jammed cylinder: The failure is mainly due to oil loss or foreign matter entering. The compressor does not run after power on, and the protector acts. 5.The thermal protector is damaged: Generally, the operating temperature becomes smaller or breaks. Open circuit will cause the compressor to not work; the smaller operating temperature point will cause the compressor to stop after a period of time and repeat this, which is easily confused with a slight short circuit between winding turns, and the working current is normal when the thermal protector is damaged, the winding To distinguish when the short circuit current is too large.

Basic solution 1. Percussion Generally choose a wooden hammer or select available objects on site. When the air conditioner compressor starts, the hammer strikes three solder joints on its body. But pay attention, don't knock out the deformation. Lightly knock on the compressor casing to loosen the stuck part slightly. Sometimes it can start running or increase the power supply voltage by 10%, and start the shock multiple times. This method can solve the phenomenon of insufficient lubrication of the cylinder. The compressor is particularly effective. 2. Strong lift Connect a plug, L is directly connected to the C end, N is connected to the M end, and another is connected to the branch line N1, and the power is turned on so that N1 point touches the start end S of the compressor. 3. Capacitive start method Increasing the capacitance is one of the most common methods. Simply put, it is to add a capacitor to the original capacitor or change a larger capacitor to increase the starting torque to make the air conditioner compressor easier to run. Note: The compressor shuts down immediately after starting two or three seconds. 4. Pressure relief method (also called decompression method) Put Freon off to reduce the pressure, and then use the above method for comprehensive utilization. 5. Air pressure impact method Disassemble the air-conditioning compressor separately, and use nitrogen gas from the high-pressure pipe to give the compressor a reaction force of 0.1MPA. Loose shaft holding parts. Take a breath for 5 minutes. Then use the above method. 6. Three-phase power start method If none of the above work, you can use the three-phase power start method. The connection method is that N is connected to C. R and S are connected to different phases of live wire. Plug in within a short time of 6 seconds. 7. Lubrication Usually there are scales inside the air-conditioning compressor, or the stuck cylinder caused by dirty things, the above will not work, remove the compressor, and pour out the oil. Add kerosene, and then pour it out, one time in a row, the purpose is to clean out the dirt inside, after washing, put the compressor upside down for 12 hours, pour out the kerosene, and volatilize. Then add No. 25 refrigeration oil, pick up the compressor and pierce the ground a few times to loosen the machine parts. Only then use the above method to start.