1. Cause Analysis of Heat Pump Cooling Failures

1.1 Insufficient Cooling Capacity - there Is Cold Air but the Room Is Not Cold Enough

a. The room is too large or the doors and windows are open. Please close the doors and windows tightly.

b. There are too many people in the room or there is a heat source. Please remove the heat source.

c. The outdoor unit is not installed in a good position suffering e.g. sun exposure and poor ventilation, causing poor heat dissipation. Please reinstall.

d. The indoor unit is not installed in a good position, causing poor air circulation. Please reinstall.

e. The filter is dirty and blocked. Please clean it.

f. The system is blocked. Check the capillary tube, filter, condenser and evaporator, etc, and clear the blockage or replace the related parts.

g. The condenser and evaporator are dirty. Please clean them.

h. Obstacles at the air inlet and outlet. Please remove them.

i. There is too much refrigerant in the system. Please release an appropriate amount of refrigerant.

j. Air is mixed in the system. Release the refrigerant in the system, and then evacuate the system and recharge the refrigerant.

k. The outdoor temperature is too high.

l. Check whether the high and low pressures are normal. If the low pressure is too high, there may be air in the system. If the low pressure is too low there may be refrigerant leakage and the system lacks refrigerant.

m. If frost forms at the capillary tube, it may be due to water mixed in the system, causing ice blockage, or it may be due to dirt blockage.

n. The compressor itself is inefficient.

o. The valve is not fully opened.

1.2 Insufficient Cooling Capacity - the Compressor Can Operate, but the Air Supply is Not Cold Enough

a. The outdoor ambient temperature is too high and the heat pump has limited capacity, it cannot cool to the desired comfortable temperature.

b. There is too much dust on the condenser, with unsmooth ventilation and poor heat dissipation effect, resulting in a decrease in the cooling capacity of the heat pump.

c. The installation location is not suitable. The outdoor unit is exposed to the sun; the position of the indoor unit is too high, too low, or at an angle, resulting in poor cold air circulation.

d. The refrigeration cycle system is blocked. When the capillary tube or the dry filter is blocked, the liquid refrigerant flowing into the evaporator is reduced, and the cooling capacity decreases.

e. Faults in the electromagnetic four-way reversing valve, the reversing valve solenoid coil, and the hot and cold switch result in poor cooling effect or no cooling.

1.3 The Compressor Stops Once It Starts

a. The outdoor unit is exposed to the sun, ventilation is blocked, etc., causing the compressor to stop due to poor condensation effect and too high discharge pressure. Please remove the obstacles.

b. Abnormally high or low voltage causes the compressor not to start. Or the overload protector is activated due to too large current and the compressor shuts down.

c. Wiring error.

d. Insufficient grid capacity, large line voltage drop, and excessive current cause the overload protector to activate and the compressor to shut down.

e. The outdoor temperature is too high. Then the condensing pressure rises, the compressor is overloaded, and the protector automatically cuts off the power supply, and finally the compressor shuts down. If the heat pump is running normally, the wind speed can be set to the medium cooling or low cooling gear to reduce the cooling load and keep the heat pump running.

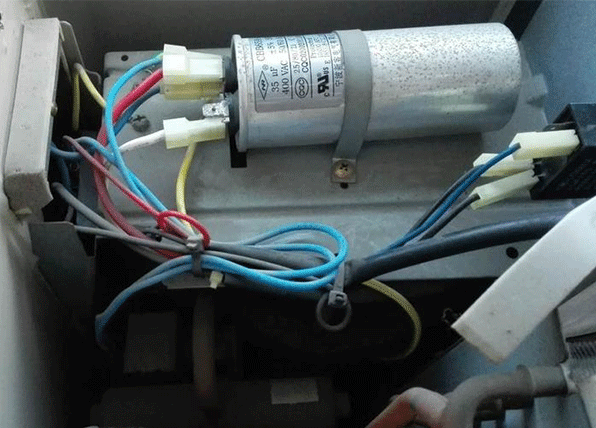

f. The capacitor has poor contact or is damaged, so that the compressor cannot operate normally.

1.4 The Heat Pump Can Operate, but It Does Not Cool and There Is No Cold Air Blowing Out

Check whether the compressor is started. If not, please do the following checks.

a. Check whether the compressor overload protector, overcurrent protector and high-voltage protection switch are disconnected.

b. Check whether the indoor temperature sensor is disconnected in the cooling state, or the temperature sensor is short-circuited in the heating state.

c. Use a multimeter to check whether the compressor relay is energized.

d. If the compressor has been started, check the system pressure. If the low pressure is too low and the connecting pipe is frosted, the refrigerant needs to be added. If the connecting pipe is not cold, it means that the refrigerant is leaking. In this case, the compressor cannot be operated for a long time, otherwise it will burn out.

2. Cause Analysis of Heat Pump Heating Failures

2.1 Insufficient Heating - there Is Hot Air, but the Room Is Not Warm

a. Improper installation position and poor air flow. Please adjust or reinstall the heat pump.

b. The filter is dirty.

c. The system is blocked. Check the capillary tube, filter, evaporator, condenser, etc.

d. The doors and windows are not closed tightly.

e. The room is too large.

f. The outdoor temperature is too low.

g. There is too thick frost on the condenser.

h. If the air volume is small, check whether the fan power is small, the capacitor is failed, the fan speed is slow or the fan is broken.

i. Insufficient refrigerant.

2.2 Insufficient Heating - the Compressor Is Running, but the Air Supply Is Not Warm Enough

a. Poor installation location.

b. Due to the low outdoor temperature, and large temperature difference between indoor and outdoor, it is difficult to let the room be warm.

c. Blockage of refrigeration cycle system.

d. Due to refrigerant leakage, the refrigeration cycle system cannot perform normal heating function.

2.3 The Compressor Stops Immediately After It Starts

a. The installation position is not good, the airflow is blocked, the condenser (indoor heat exchanger) does not work well, and the compressor automatically shuts down due to too high discharge pressure.

b. Voltage is too low or too high, and the compressor protector is activated.

c. Insufficient power capacity, large line voltage drop, and excessive compressor current cause the compressor protector to activate.

d. Poor contact or damage of the capacitor prevents the compressor from operating normally.

2.4 Outdoor Fan Motor Does Not Rotate

a. The main fault is poor contact of the plug or broken power cord. Please check the power cord and the plug.

b. It may be caused by poor electrical contact or faulty thermostat. Find out the cause and repair or replace components.

c. The capacitor has poor contact or is damaged and needs to be repaired.

d. Parts are disconnected or the fan motor loses power. Find out the cause and repair them.

e. Check whether the fan blades are stuck and whether the fan motor windings are damaged. If damaged, they should be replaced.

2.5 No Heating - the Outdoor Fan Motor Can Rotate, but the Compressor Does Not Work

a. The voltage is too low or too high, and the current is large, causing the compressor protector to operate.

b. The power supply capacity is too small, the voltage drop is large, and the compressor shuts down for protection.

c. There is a problem with the electrical circuit and the compressor cannot operate.

d. The compressor itself is faulty and needs to be replaced.

2.6 The Compressor Can Work, but There Is No Hot Air Indoors

a. The refrigeration cycle system is leaking.

b. The refrigeration cycle system is blocked.

c. The compressor valve is leaking or broken, causing the compressor not to compress gas although it is running.

d. The four-way valve is faulty and does not reverse. Please check the circuit or replace the four-way valve.

3. Cause Analysis of Heat Pump Unit Failures

3.1 No Response When the Heat Pump Is Powered On

1) Check whether the power supply or plug is in poor contact. If normal, check the wiring board.

2) Check if the fuse is blown, if the varistor is burnt out, and if the transformer voltage output is normal.

3) If the transformer is normal, check if the voltage regulator has 12V and 6V outputs.

4) If the voltage regulator is normal, check if the main chip has 5V input and if there is 2.2V voltage at both ends of the crystal oscillator. If not, it is a chip problem.

5) Check whether the L line and the COMP line are plugged in reverse.

6) Check whether there is a wiring problem between the internal and external units.

3.2 The Heat Pump Is Noisy

1) The internal fan or fan blades are not installed properly.

2) The external fan blades collide with the shell.

3) The shell screws are loose.

4) The pipeline collides with the compressor or shell.

5) There is air mixed in the system.

6) Compressor failure.

7) If it is caused by liquid slugging, release excess refrigerant.

8) The sheet metal parts vibrate greatly, and damping blocks need to be added to the vibration area.

3.3 The Heat Pump Is Frequently Turned On and Off

1) If the voltage is abnormal, please improve the power supply conditions and use a voltage regulator.

2) The condenser has poor heat dissipation and poor ventilation. Please clean the dust on the condenser and remove obstacles from the air outlet.

3) Excessive refrigerant filling.

4) The outdoor temperature is too high.