1. Refrigerant Leakage

[Fault analysis] After the refrigerant leaks in the system, the cooling capacity is insufficient, the suction and discharge pressures are low, and a much larger intermittent "squeaking" airflow sound can be heard at the expansion valve than usual. The evaporator does not frost or a small amount of frost is formed on it. If the expansion valve opening degree is adjusted, the suction pressure still does not change much. After shutdown, the balance pressure in the system is generally lower than the saturation pressure corresponding to the same ambient temperature.

[Troubleshooting method] After the refrigerant leaks, do not rush to fill the system with refrigerant, but immediately find and repair the leakage point and then refill the system.

2. Too Much Refrigerant Is Filled after Maintenance

[Fault analysis] If the amount of refrigerant filled in the refrigeration system after maintenance exceeds the capacity of the system, the refrigerant will occupy a certain volume of the condenser, which will reduce the heat dissipation area, reduce the refrigeration efficiency of the system, and cause the suction and exhaust pressures to be generally higher than the normal pressure value.

[Troubleshooting method] According to the operating procedure, the excess refrigerant must be discharged at the high-pressure stop valve after the machine is shut down for a few minutes. At this time, the residual air in the system can also be released.

3. There Is Air in the Refrigeration System

[Fault analysis] If there is air in the system, the discharge pressure will be too high, the discharge temperature will be high, the discharge pipe will be hot, the cooling effect will be poor, and the discharge pressure will exceed the normal value after the refrigeration compressor has been running for a short time.

[Troubleshooting method] The air can be discharged from the high-pressure stop valve several times in a row after stopping the machine for a few minutes, and some refrigerant can also be appropriately filled in the system according to the actual situation.

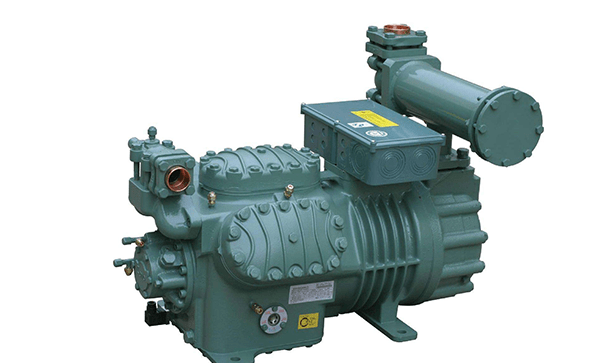

4. Low Efficiency of the Refrigeration Compressor

[Fault analysis] The low efficiency of the refrigeration compressor means that the actual discharge volume decreases under the same working conditions, resulting in a corresponding decrease in the cooling capacity. This phenomenon often occurs on compressors that have been used for a long time, with large wear, large clearance between components, and reduced sealing performance of the air valve, resulting in a decrease in the actual discharge volume.

[Troubleshooting method] Check whether the sealing gasket is damaged to cause leakage; check whether the high and low pressure discharge valve plates are not closed tightly; check the clearance between the piston and the cylinder.

5. Too Thick Frost on the Evaporator Surface

[Fault analysis] The cold storage evaporator used for a long time needs to be defrosted regularly. If it is not defrosted, the frost layer on the evaporator pipeline will become thicker and thicker. When the frost covering the entire pipeline becomes a transparent ice layer, it will seriously affect the heat transfer, causing the temperature in the warehouse to not fall to the required range.

[Troubleshooting method] Stop the machine for defrosting, open the door to allow air circulation, or use a fan to accelerate the circulation to reduce the defrosting time.

6. There Is Refrigeration Oil in the Evaporator Pipeline

[Fault analysis] During the refrigeration cycle, some refrigeration oil remains in the evaporator pipeline. After a long period of use, when there is more residual oil in the evaporator, it will seriously affect its heat transfer effect and cause poor refrigeration.

[Troubleshooting method] Clear the refrigeration oil in the evaporator. Remove the evaporator, purge it and then dry it. If it is not easy to remove, you can use an air compressor to inflate the evaporator inlet, and then dry it with a blowtorch.

7. Blocked Refrigeration System

[Fault analysis] Due to the poor cleaning of the refrigeration system, after a period of use, dirt gradually accumulates in the filter, and some meshes are blocked, resulting in a reduction in the refrigerant flow rate to affect the refrigeration effect. The filter screens at the expansion valve and the compressor gas intake in the system are also slightly blocked.

[Troubleshooting method] The slightly blocked parts can be removed, cleaned, and dried before being installed.

8. Blocked Filter

[Fault analysis] The desiccant has been used for a long time and has become a paste that blocks the filter, or dirt gradually accumulates in the filter and causes blockage.

[Troubleshooting method] Remove the filter, clean and dry it. Replace the desiccant, and then install the filter in the system.

9. Refrigerant-Like Substance Leaks in the Expansion Valve Sensing Bulb

[Fault analysis] After the refrigerant-like substance in the expansion valve temperature sensing bulb leaks, the two forces under the diaphragm push the diaphragm upward, closing the valve, and the refrigerant in the system cannot pass through, resulting in no refrigeration. At this time, the expansion valve does not frost, and no airflow sound can be heard in the evaporator.

[Troubleshooting method] Shut down the machine, close the stop valve, and remove the expansion valve to check whether the filter is blocked. If not, blow the expansion valve inlet with your mouth to see if it is ventilated. You can also visually inspect or disassemble it for inspection, and replace it if it is damaged.

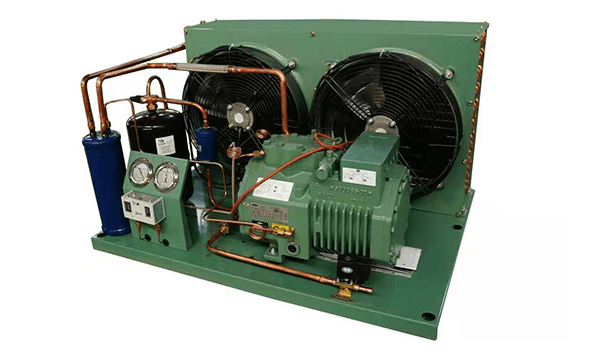

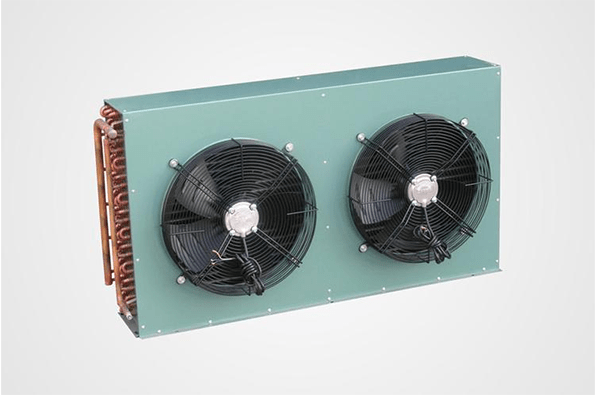

10. The Air-Cooled Condenser in a Cold Storage Has Poor Heat Dissipation Effect

[Fault analysis]

① The fan is not turned on.

② The fan motor is damaged.

③ The rotation direction of the fan is reversed.

④ The ambient temperature is high (above 40°C).

⑤ The condenser fins are blocked by oil and dust, causing the surrounding air to stagnate.

[Troubleshooting method] Use a brush to remove surface dust, or rinse it.

11. The Water-Cooled Condenser in a Cold Storage Has Poor Heat Dissipation Effect

[Fault analysis]

① The cooling water valve is not opened or opened too small, and the water inlet pressure is too low.

② The water flow regulating valve fails.

③ The scale on the condenser tube wall is thick.

[Troubleshooting method] Check the cooling water flow, and remove the scale.

12. Too Much Refrigerant Is Charged into the System

[Fault analysis] Excessive refrigerant causes the discharge pressure to rise significantly, exceeding the normal value.

[Troubleshooting method] Shut down the machine and discharge the excess refrigerant out of the system through the high-pressure exhaust hole.

13. Motor Overload

[Fault analysis]

1. Too much or excessive food is put into the warehouse during use;

2. The power supply is abnormal.

[Troubleshooting method] Reduce the heat load and pay attention to the change of power supply voltage.

15. Temperature Controller out of Control

[Fault analysis] The temperature controller adjustment fails or the temperature sensing bulb is improperly installed.

[Troubleshooting method] Remove the temperature controller to inspect its contacts, adjust it, and adjust the position of the temperature sensing bulb. If needed, replace the temperature controller.

14. Shutdown Caused by Too Low Suction Pressure

[Fault analysis] When the suction pressure in the system is lower than the set value of the pressure relay, its contacts act and cut off the power supply.

[Troubleshooting method] Check the cause and eliminate it: refrigerant leakage or blockage in the system.

16. Sudden Shutdown Caused by Other Reasons

[Fault analysis] During use and maintenance, it is often necessary to open and close the stop valves of discharge, suction, and liquid storage. Sometimes the stop valve is not opened due to negligence, causing a sudden increase in discharge pressure.

[Troubleshooting method] Shut down the machine immediately to prevent danger.