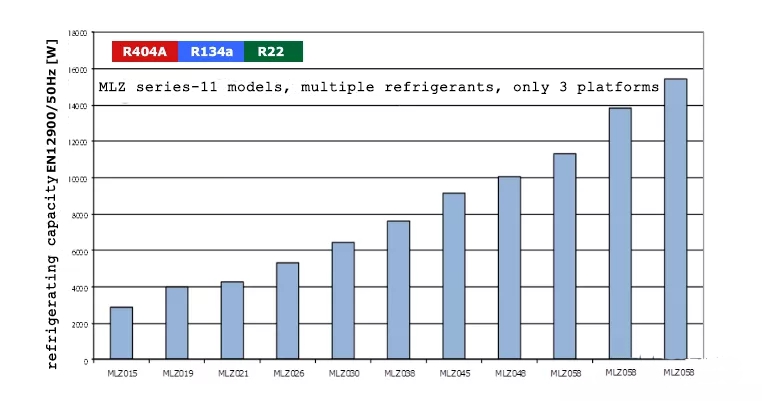

Danfoss expert analysis! Causes and troubleshooting of compressor start-up with liquid 1. Liquid back: When the refrigerant returned to the compressor is not a pure gas state, but contains liquid, the influence of the liquid refrigerant on the compressor is negative. If there is too much liquid, it may even cause liquid shock, even if there is no liquid shock, it will happen. Wet compression causes oil to run away. There is also an impact on lubrication. There is a great possibility that some of the refrigerant liquid will run into the lubricating oil sump of the compressor. Different compressors will have different amounts of liquid refrigerant returning to the oil sump according to the design of the internal refrigerant channel. All friction The difference in the material of the force acting surface and the magnitude of the acting force also have different requirements for lubrication, and the final ability to resist liquid back is different. As shown in the figure below, they are the cross-sectional views of Danfoss' 10Hp refrigeration scroll compressor and 15Hp refrigeration scroll compressor. The internal structure of the two types of compressors is very different, and the ability to resist liquid back is also different.

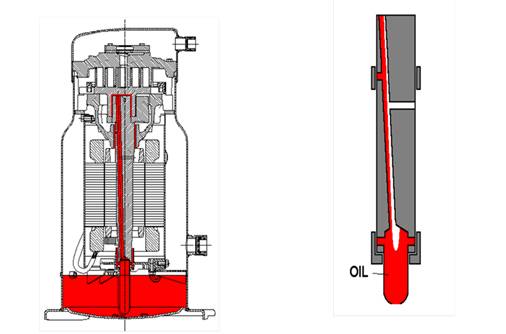

Figure 1-4. Cross-sectional view of 10Hp and 15Hp refrigeration scroll compressors The suction port of the 10Hp compressor is located on the upper part of the stator coil of the motor. When the refrigerant sucked into the compressor in the form of gas-liquid mixture, part of the liquid directly enters the compression chamber with the gas. A small part of the liquid does not have time to complete the gasification, which will cause liquid compression, but the compressor is a flexible design that can be separated between the scroll disks and bypass the liquid to form a self-protection to prevent the liquid compression from destroying the vortex Disk wall surface. The other part of the liquid will be separated from the gas and run down the gap between the electronic rotor, stator and housing. During the process, the liquid will be evaporated into gas by the heat of the motor, and the oil will drip into the oil sump and start again. New cycle. The position of the suction port of the 15Hp compressor is different, but after the refrigerant is sucked into the compressor, it cannot be directly sucked into the compression chamber. No matter what the phase state of the sucked refrigerant is, it will run downward, passing through the surface of the oil sump, from the motor stator and rotor The gap between them is upward, and finally enters the compression chamber through the bearing bracket; in this process, the gas, liquid, and oil in the refrigerant will have a separation effect, the liquid will be evaporated, and the oil will drip into the oil sump and restart cycle. Only gas will enter the compression chamber upwards. Regardless of the 10Hp or 15Hp refrigeration scroll compressor, no matter how reasonable the structural design, there will be a possibility that the liquid in the drawn refrigerant enters the oil sump, dissolves with the lubricating oil, dilutes the lubricating oil, and eventually causes the lubricating oil The dynamic viscosity of the compressor is reduced, and the lubrication effect is greatly affected. This will cause the main bearing of the compressor to wear due to the reduction of the lubrication effect, which may eventually cause the shaft to hold or even the motor to burn out. The design of the Danfoss compressor has avoided this as far as possible. The path of the refrigerant to the oil pond has been specially designed to separate and evaporate the liquid. At the same time, the most important thing is that the bearing material has been updated. Of the refrigeration scroll compressors use lead-free Teflon bearings or carbon bearings, which can withstand boundary lubrication conditions or even dry lubrication. In the cold storage industry, for liquid return, the prevention measures are mainly in the system design, which can have the following aspects: 1. Install the gas-liquid separator and design the oil return hole reasonably 2. Effective and timely defrosting. 3. Reasonably match the heat exchange capacity of the evaporator, especially for the capacity of the cooling fan and the exhaust pipe in the cold storage. 4. Reasonable selection of thermal expansion valve, especially in applications with large fluctuations in load. 2. Start with liquid: 1. First, let's define what is called liquid start. When the refrigeration unit is stopped, there is refrigerant liquid in the compressor casing. The next time the compressor is started, the refrigerant liquid will damage the lubrication of the compressor. Starting the compressor with refrigerant liquid Called to start with liquid. 2. Then let's take a look at the process of destroying the compressor with liquid start: When refrigerant liquid appears in the compressor casing, the liquid tends to stay at the bottom of the compressor and is mixed with the lubricating oil. The lubricating oil and the refrigerant are generally soluble in each other. The solubility and temperature, additives and other conditions are related. Lubrication After the oil and refrigerant are mixed, the characteristics of the lubricating oil will change. The most obvious is that the dynamic viscosity will decrease, which will directly affect the lubrication effect. When the compressor is started again, the motor of the scroll compressor is generally It is directly driven by three-phase power supply, and soft starter will not be installed in most cases. In this way, the pressure in the compressor casing drops sharply in an instant, and it is below the saturation pressure of the refrigerant at the current temperature. This will cause the refrigerant liquid in the lubricating oil to evaporate rapidly, boiling, and a large amount of foam. If you look at the oil sight glass of the compressor, as shown below.

Figure 1-5 Compressor oil pool sight glass when the unit starts with liquid A The operating channel of the lubricating oil in the compressor is shown in the following figure. There are generally four parts inside the compressor that need oil lubrication, the lower bearing, the main bearing, the upper bearing and the scroll. The three bearings are matched with the rotating crankshaft to ensure coaxiality, while relative displacement occurs, friction occurs, and oil lubrication is required. The lower bearing is very close to the oil sump, and even the lower bearing of some compressors is designed to be immersed in the oil sump (such as the Danfoss Pfima H and M series compressors), so in general, the lower bearing is the easiest to get There is no need to worry about lubrication problems in the oil parts; The oil of the main bearing and the upper bearing is thrown up by the centrifugal force generated by the eccentric hole inside the crankshaft when the crankshaft is running. If a large amount of foam is generated, the foam will block the eccentric hole of the lubricating oil and at the same time The oil film is cleaned, and the friction surface is rubbed without sufficient lubrication conditions, which will lead to wear. Seriously, it will cause the cylinder to hold the shaft. The most affected by liquid start is the uppermost part of the shaft and the dynamic bearing. Because this part is the highest position, It is the most difficult to obtain lubricating oil, so it will be worn first and cause the compressor to break down.

Figure 2. Cross-sectional view of an air-conditioning scroll compressor A 3. Let's analyze the cause of the start with liquid In a normally operating system, there should be no refrigerant liquid in the compressor, but immediately after shutdown, the compressor housing is the lowest pressure point of the entire system, the high pressure side is still high pressure, the system pressure needs to be balanced, and a lot of refrigeration The refrigerant liquid will continue to flow under the effect of the pressure difference. After the evaporator of the system also stops working, no heat is input, and the refrigerant will migrate to the compressor casing in the form of liquid. On the other hand, after shutdown, the refrigerant in the unit must be in a state of gas-liquid mixing, and the liquid will migrate to a lower position. In a closed environment, the liquid is also likely to gather in a place with a low temperature. The location of the temperature is often not high, and the location is also low, which also increases the possibility of liquid refrigerant accumulation. 4. Let's take another look at the measures to prevent the start of the liquid with the refrigerant migration. Danfoss has the following three suggestions: 1. Install the liquid pipe solenoid valve. After the unit is shut down, close the solenoid valve at the same time to trap most of the refrigerant liquid on the high pressure side, which greatly reduces the possibility of starting with liquid. 2. Install the electric heating belt of the compressor. After the compressor stops, the electric heating belt is powered on to heat the oil sump, maintain the heat input, maintain the high temperature of the oil sump, and evaporate the refrigerant liquid in the oil sump to avoid the next time. The effect of starting liquid foam. 3. The design of the return air line is inverted U-shaped to prevent the liquid in the evaporator from migrating to the compressor due to the self-weight due to the height difference between the evaporator and the compressor after the shutdown. The evaporator advances in the next start Operation, to evaporate liquid into gas, can ensure safety. 4. Install the gas-liquid separator. 3. Liquid strike: Liquid shock occurs inside the compressor, which means that there is enough refrigerant liquid to enter, and the liquid compression occurs, resulting in hard damage to the compression components, such as the scroll disk or the cross ring broken or even broken. The debris of these mechanical parts entering the motor will also cause the motor to burn out. There are several reasons for the liquid blow:

At the installation site of the unit, due to the lack of experience of the installer, after the evacuation is completed, the refrigerant is directly charged at the suction and exhaust ports of the compressor (the general cold storage unit has an angle valve here), and it is directly started after the charging Cause liquid hammer. During the commissioning phase and even the stable operation phase of the unit, due to the problems of terminal matching, valve selection, and abnormalities on the evaporation side, etc., the unit returned a large amount of liquid in a short period of time, resulting in liquid shock. When the unit is shut down, the refrigerant transfers too much, and finally the compressor cavity in the compressor is also filled with refrigerant liquid, and liquid shock occurs at the next start. The measures to prevent liquid hammering are completely formulated according to the reasons, including the operation instructions of the installation procedures of the unit, the early selection of the system and the matching of on-site commissioning, and various measures to prevent the migration of refrigerant. Danfoss' refrigeration scroll compressors used in cold storage are 2~10Hp, which adopts flexible sealing technology, and the movable scroll disk is flexible fixed. The centrifugal force and the force generated by the gas pressure difference are used to maintain the seal. When liquid compression occurs, the scroll disk can If detachment occurs, the liquid will be bypassed and discharged, which will not cause hard damage to the scroll, and can prevent a certain degree of liquid impact.