Video: EC Fan: Everything You Need to Know

Figure 1: EC fan.

In the realm of modern ventilation and air circulation systems, Electronically Commutated (EC) fans have emerged as a groundbreaking technology. These fans are transforming the way we think about energy efficiency and environmental sustainability. In this comprehensive guide, we will explore the fundamental aspects of EC fans, their advantages, the key distinctions that set them apart from conventional fans, and applications.

1. What is an EC Fan?

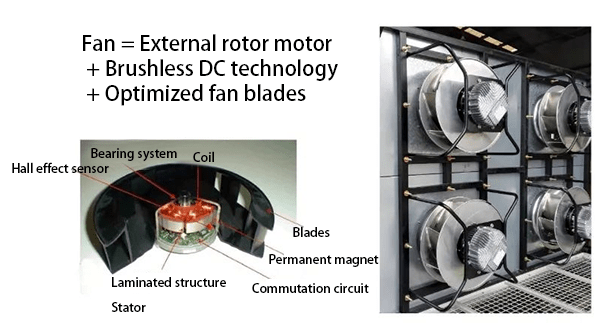

EC fans are also called AEC or ADC fans. EC motors are "electronically commutated". They use built-in electronic circuitry to control the speed and direction of motor rotation, achieving greater energy efficiency and quieter operation compared to traditional DC fans that rely on mechanical brushes for commutation.

The working principle of EC fans is equivalent to DC fans. The difference is the power input of EC fans is AC voltage, which is then converted into DC voltage through a module. And then connect the fan with DC structure (EC fan) to the circuit. This feature makes them easy to be retrofitted and provides better control and greater efficiency.

Figure 2: Components of EC fan.

2. Advantages of EC Fans

Energy Efficiency

The standout advantage of EC fans is their remarkable energy efficiency. The electronic commutation technology allows for dynamic control of the motor speed. This means that the fan can operate at varying speeds, adjusting to the specific needs of the moment. As a result, EC fans are incredibly efficient, consuming only the necessary amount of energy to maintain the desired airflow.

Variable Speed Capabilities

EC fans boast variable speed capabilities, a feature that sets them apart from traditional fans. The ability to modulate the fan speed based on demand makes EC fans exceptionally versatile. In applications like Heating, Ventilation, and Air Conditioning (HVAC) systems, where airflow requirements fluctuate, EC fans excel in providing precise and adaptable solutions.

Quiet Operation

Another noteworthy advantage is the quiet operation of EC fans. The brushless DC motor design not only enhances energy efficiency but also reduces noise levels significantly. This makes EC fans ideal for environments where low noise is crucial, such as offices, residential spaces, or libraries.

Reduced Carbon Footprint

The energy efficiency of EC fans directly translates into a reduced carbon footprint. As industries and businesses strive to meet sustainability goals, the adoption of EC fan technology aligns with environmental conservation efforts.

Compliance with Energy Standards

Many countries and regions have established energy efficiency standards to curb energy consumption and promote sustainable practices. EC fans, meeting and often exceeding these standards, play a vital role in helping businesses comply with regulatory requirements.

Longevity and Maintenance Savings

The durability of EC fans contributes to longer operational lifespans, resulting in reduced replacement frequency and associated material consumption. Lower maintenance requirements further enhance the environmental benefits by decreasing the need for spare parts and repairs.

Figure 3: ebm-papst EC external rotor fan motor.

3. Difference Between EC Fans and Conventional Fans

Motor Technology

The primary distinction lies in motor technology. Conventional fans typically use AC motors, which operate based on the principles of electromagnetic induction. In contrast, EC fans employ brushless DC motors with electronic commutation. The elimination of brushes in EC fans not only enhances efficiency but also contributes to a longer lifespan.

Figure 4: EC fan motor controller.

Energy Consumption

Conventional fans operate at a fixed speed, leading to constant energy consumption, irrespective of the actual demand for airflow. On the other hand, EC fans' ability to modulate speed based on demand results in energy savings. This dynamic control ensures that the fan consumes only the necessary amount of energy, making EC fans a more sustainable and cost-effective choice.

Control and Precision

EC fans offer precise control over the speed and direction of the fan, thanks to the electronic commutation technology. This level of control is not achievable with conventional fans, which operate at a fixed speed. The variable speed capabilities of EC fans make them adaptable to a wide range of applications, providing optimal performance in various scenarios.

Environmental Impact

The energy efficiency of EC fans translates into a reduced environmental impact. With the global emphasis on sustainability, businesses and industries are increasingly turning to EC fans to meet energy efficiency standards and reduce their carbon footprint. Conventional fans, operating at a constant speed, struggle to match the environmental benefits offered by their EC counterparts.

4. Applications of EC Fans

HVAC Systems

EC fans are widely used in Heating, Ventilation, and Air Conditioning (HVAC) systems. Their variable speed capabilities enable HVAC systems to adapt to changing conditions, optimizing energy usage while maintaining a comfortable environment. The efficiency gains in HVAC applications contribute significantly to overall energy savings.

Refrigeration and Cooling Systems

In refrigeration and cooling applications, EC fans offer precise control over airflow, ensuring optimal temperature regulation. Their ability to operate at different speeds allows for efficient heat exchange, leading to improved cooling performance and reduced energy consumption.

Data Centers

The demand for precise temperature control in data centers makes EC fans an excellent choice. These fans can adapt to varying heat loads, providing a cost-effective solution for maintaining optimal operating conditions in server rooms.

Industrial Ventilation

EC fans find applications in various industrial settings where effective ventilation is crucial. Their adaptability and energy efficiency make them suitable for maintaining air quality in manufacturing facilities, warehouses, and other industrial environments.

Figure 5: EC fans with DC brushless external rotor motor.

5. Conclusion

In conclusion, the Electronically Commutated (EC) fan represents a paradigm shift in fan technology. Its energy efficiency, variable speed capabilities, and environmental benefits make it a preferred choice in the quest for sustainable solutions.

As we continue to prioritize efficiency and environmental responsibility, EC fans are poised to play a crucial role in shaping the future of air circulation systems. Whether in HVAC applications, industrial settings, or residential spaces, the advantages of EC fans make them a compelling choice for those seeking optimal performance with a reduced ecological footprint.