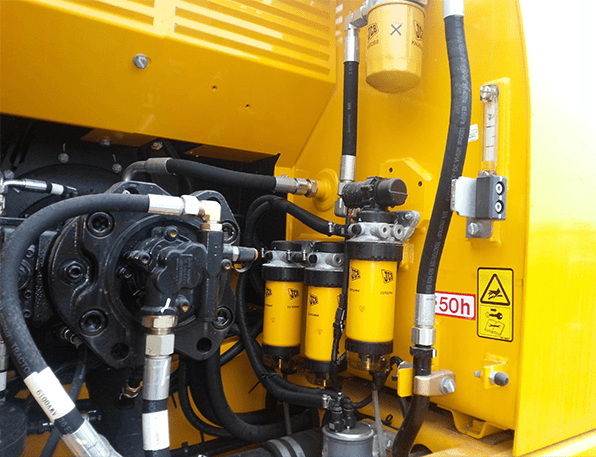

The hydraulic system is composed of various hydraulic components, which are organically connected by pipes, joints, oil pipes and other components.

Before installing the hydraulic device, preparations should be made in accordance with relevant technical data.

1. Preparations before Installing the Excavator Hydraulic System

Preparation of drawings and technical data:

Hydraulic system schematic diagram, pipeline layout, component list, pipe fittings list, and relevant samples.

Material preparation:

(I) Check the quality of hydraulic components

Whether the performance of the hydraulic components used meets the requirements is directly related to the reliability and stability of the system. Therefore, maintenance personnel must strictly control the quality.

(II) Contents to be checked

1. The models and specifications of various hydraulic components used must be consistent with the component list.

2. Check whether the storage period is too long. If it is too long, be sure to pay attention to whether the seals are aging.

3. The adjusting screws, handwheels, locking nuts, etc. on each component must be intact.

4. Check whether the quality of the attached seals meets the requirements. If there are any abnormalities, they must not be used and must be replaced.

5. Open the plugs of each oil port and check whether the interior is clean.

6. The valve solenoid must not have any abnormalities, and the valve matching accessories must be complete.

1.1 Disassembly and Testing of Hydraulic Components

1. Disassembly and Cleaning

When disassembling and cleaning hydraulic components, you must first be familiar with the structure, function and principle of the components, and carefully disassemble and assemble them.

● Do not damage or lose parts during disassembly and cleaning.

● Do not use fibers such as cotton cloth to wipe the parts. After cleaning, all oil ports must be sealed with plastic plugs.

● Assemble according to the drawings, and do not install the parts or seals incorrectly.

● When tightening the screws, apply torque evenly and never hit them with a hammer.

2. Testing

The test is to conduct reliability tests on the disassembled and cleaned hydraulic components or new components. If conditions permit, they must be tested before installation. Each tested component must meet the main indicators specified by the product. Those that do not meet the requirements cannot be installed in the equipment. At the same time, the tested parts must be sealed and protected.

2. Installation Requirements for Excavator Hydraulic Systems

For the automatic lines of large equipment, the hydraulic system is relatively complex, with many components and pipes, and the pipes are long and crossed. Therefore, the installation requirements of the hydraulic system are very strict.

Hydraulic pipeline installation is a major project of hydraulic equipment. The quality of pipeline installation is one of the keys to whether the working performance of the hydraulic system can be normal for each hydraulic component. There are certain requirements for each hydraulic component and each related part and pipeline.

2.1 Pipeline Installation Requirements

1. Ensure that all pipes are clean before installation.

2. The number of crosswise installed pipes should be minimized, and the distance between pipes and pipes, and between pipes and equipment should be more than 10mm. At the same time, pipe clamps should be installed at a certain distance to prevent mutual interference and knocking caused by vibration.

3. It is not allowed to use right-angle joints made of pipes. Each joint must be tightly sealed and no leakage is allowed.

4. The pipes should be neatly, tightly arranged, easy to disassemble and repair.

2.2 Joint and Flange Cover Installation Requirements

First, clean, and tighten them evenly with sufficient tightening torque, etc.

2.3 Hose Installation Requirements

1. Install according to the requirements specified in the design drawings.

2. The hose has a -4% to +2% extension and contraction change under pressure changes, and it is not allowed to be in a tensioned state.

3. Twisting state is not allowed.

4. Add protective devices (drag chains, steel wire wrapping, etc.) to places with friction.

2.4 Suction Pipe Installation Requirements

1. The connection between the suction pipe and the hydraulic pump should be tightly sealed. The pump suction height is not more than 500mm.

2. Install a filter on the suction pipe.

3. Check the Installation Quality

If there is any error in the installation process, it should be eliminated before testing. The contents to be checked for installation quality are as follows:

1. All parts must be clean. No dirt is allowed to be left on the moving surfaces.

2. The connection of each pipe and joint must be correct, firm and reliable.

3. The pressure gauge switch should be closed, and the installation position of each component is in accordance with the schematic diagram.

4. Some hose protection devices should be installed.

4. Cleaning System

For newly manufactured or repaired hydraulic equipment, after the hydraulic system is installed, to ensure the normal operation of the system, the pipeline, oil channel, oil tank, etc. must be cleaned circularly before the test run.

Cleaning method:

1. Use a special cleaning oil with low viscosity for cleaning, and heat it to above 50 degrees.

2. The cleaning work is mainly based on the main pipeline system.

3. During the cleaning process, tap the pipe frequently and gently, and remove the oil filter to clean the filter element.

4. The cleaning oil must be drained after cleaning. Prevent it from mixing with the hydraulic oil.

5. Finally, add oil according to the oil specified in the equipment manual. And make preparations for the test run.

5. Hydraulic System Testing

Purpose and content

1. The purpose of testing is to verify whether the designed and installed hydraulic system is qualified. Operation testing and adjustment is to adjust the hydraulic system to the best operating state under the premise of meeting the process requirements.

2. Content: The following must be within the values required by the process: the force, torque, speed, acceleration, start, brake, starting and end points of the stroke of each action that constitutes the working cycle, the time occupied by each action, and the total time required for the entire automatic cycle.

Precautions

1. First, perform idling, remove the air in the hydraulic system, check the liquid level in the oil tank, and check the indication value of the instrument.

2. During the testing and adjusting process, if a fault occurs, the first thing to do is to carefully analyze the cause, determine the cause through simple experiments, and take correct elimination measures. Do not dismantle and disassemble without thinking, and do not use intuition to find the cause of the fault.

3. If a fault is difficult to eliminate immediately, you can consider bypassing it and continue with the certain testing and adjusting sequence, leaving the fault to be solved last. This will help shorten the testing and adjusting time.