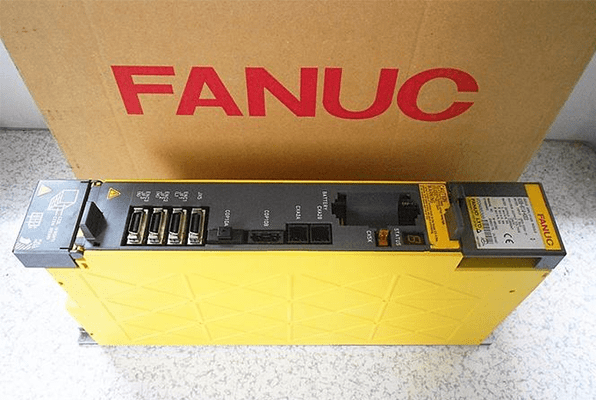

Relying on its strong R&D capabilities and rigorous work style, FANUC continues to develop epoch-making products, making the FANUC CNC system one of the most widely used and recognized systems on the market today.

The powerful fault self-diagnosis function of the FANUC system provides a strong guarantee for users to use the FANUC system more safely and reliably. When you encounter a system failure alarm, in addition to consulting FANUC after-sales service immediately, you can also make a rough judgment on most faults based on the system's self-diagnostic alarm codes.

Below we will introduce you to the meanings and solutions of common alarm codes in the FANUC servo amplifier in 3 articles, so that you can better use FANUC products.

1. FANUC Servo Amplifier Alarm Codes and Troubleshooting Methods

1.1 SV0401 Servo Amplifier READY Signal (DRDY) Went Off

Reasons for alarm:

This alarm occurs when the servo amplifier READY signal has not been turned ON, or when it is turned OFF during operation.

Solutions:

1) Check the diagnosis number 358 and confirm that the emergency stop related wiring should be checked first.

2) The servo amplifier or axis control card hardware may be damaged, and replace the hardware.

1.2 SV0403 Hardware/Software Mismatch

Reasons for alarm:

The combination of Fanuc axis control card and servo software is incorrect. Possible reasons are:

1) The correct axis control card is not provided;

2) The correct servo software is not installed in the flash memory.

Solutions: If the software or hardware is abnormal, please contact the FANUC maintenance department directly.

1.3 SV0404 Servo READY Signal Is Always On

Reason for alarm:

This alarm occurs when the servo READY signal of the servo amplifier is always ON.

Solutions:

1) In some special cases, you can use parameter P1800#1=1 for shielding;

2) If the amplifier or axis control card is damaged, replace the amplifier or axis control card.

1.4 SV0409 Torque Abnormality

Reason for alarm:

After the system turns on the abnormal torque load alarm function, it detects abnormal load.

Solutions:

1) If you do not use abnormal load detection function, please set parameter P2016#0=0;

2) If you use the abnormal load detection function, please confirm whether there is any abnormal load phenomenon, such as machine abnormally stuck or abnormal processing status;

3) If the abnormal load detection function is used and at the same time the processing status is normal, please readjust the relevant parameters of this function.

1.5 SV0410 Too Large Position Deviation Value When the n–th Axis Stopping

Reason for alarm: The alarm is caused by excessive error when the servo axis stops.

Solutions:

1) Check whether the power line and feedback line are connected incorrectly;

2) Check whether the servo motor initialization parameters are incorrect;

3) Correctly set the error alarm level parameters P1829, P5312, etc. when the servo axis stops in different states;

4) If the servo motor vibrates during use, please check the jitter problem first. At this time SV0410 is an additional alarm;

5) If this problem occurs during Cs axis control, please check the relevant parameters of the spindle encoder.

1.6 SV0413 n–th Axis - LSI Overflow

Reason for alarm:The position deviation counter overflows.

Under normal circumstances, the command value and feedback value are basically the same, and the value in the error register is generated by subtracting the command value from feedback value, which is close to zero.

However, if the direction of the command value and the feedback value are opposite or only the command/feedback end continues to change, it will cause the value in the error register to become larger and larger until it exceeds the threshold value and an alarm occurs.

Solutions:

1) If the machine tool is running normally, there are commands and feedback, and the feedback distance is normal, it is confirmed that the command and feedback directions are opposite. At this time, please switch 3706#6#7, switch M03, M04 and G70.5, G70.4, or try to change the programming method.

2) If the machine tool only has command output but no actual feedback, please confirm the machine tool operating status, functions or peripheral hardware.

3) If the machine tool has actual feedback but no command output, such as vertical lathe CF axis control mode, please use the control axis removal function.

1.7 SV0415 n–th Axis – Excess Shift

Reason for alarm: A set speed is exceeding the movement speed limit.

Solutions:

1) Reduce the command speed.

2) For gear processing under FSC+PMC+CS control mode, you can try the following solutions:

① Modify parameter P2068=0;

② Modify parameter P8003#3=1;

③Set parameters P8005#4 and P8007#2 according to the actual situation.

1.8 SV0417 Illegal DGTL Parameter

Reason for alarm: The parameter setting value for digital servo is abnormal.

Solutions: See Diagnosis N203#4.

1) Diagnose N203#4=0.

Illegal parameters were detected through the CNC software. This may be due to the following reasons (See diagnostic message No. 280):

①The motor model in parameter (No. 2020) is set to a value outside the specified range;

②The correct value (111 or -111) has not been set in the motor rotation direction of parameter (No. 2022);

③The number of speed feedback pulses per motor revolution in parameter (No. 2023) is set to an incorrect value such as 0 or below;

④The number of position feedback pulses per motor revolution in parameter (No. 2024) is set to an incorrect value such as 0 or less.

2) Diagnose N203#4=1.

Refer to the specific values in diagnosis N352 and check the table to find the problem. For specific tables, please refer to the FANUC system maintenance instructions.

1.9 SV0420 Too Large Synchronous Torque Difference

Reason for alarm: During the synchronous operation of the feed axis synchronous control, the torque difference between the master axis and the slave axis exceeds the set value.

Solutions:

1) Confirm whether the torque difference is too large, and find the torque balance position of the mechanical master and slave axes, etc.;

2) Confirm whether the two-axis parameter settings, axis initialization parameters, etc. are correct;

3) Modify the alarm threshold, parameter P2031.

1.10 5SV0421 n Axis Excess ER (Semi-Closed Loop)

Reason for alarm: The fully closed-loop feedback data and semi-closed-loop calculation data exceed the setting value of parameter P2118.

Solutions:

1) Check whether the flexible gear ratio and dual position feedback conversion coefficient settings are correct;

2) Modify the grating ruler detection direction, parameter P2018#0;

3) Check whether there is poor hardware installation or hardware damage.

1.11 SV0422 Overspeed in Torque Control

Reason for alarm: The speed has exceeded the allowable speed specified in torque control.

Solutions: Please check the torque setting value and speed limit value in the torque control command.

1.12 SV0423 Too Large Torque Control Error

Reason for alarm: In torque control, the parameter–set allowable cumulative travel distance has been exceeded.

Solutions:

1) Shield this alarm: P1803#4=0, P1805#1=1;

2) Adjust the error threshold parameter P1885;

3) Check the actual situation and reduce the error.