Ford Explorer air conditioner fails to refrigerate troubleshooting

Trouble phenomenon: A 2017 Ford Explorer with a mileage of about 36,000 km and a dual-zone automatic temperature control air-conditioning system. User feedback: The air conditioner has insufficient cooling during the use of the car. That is, after pressing the A/C switch and turning the air conditioner control panel to the cooling state at the same time, the cooling effect is poor, and the air outlet temperature is not much different from when the A/C switch is not turned on.

Fault diagnosis: first verify the fault phenomenon, start the vehicle and turn on the air conditioner A/C and adjust the temperature to the lowest. After a period of time, the air from the indoor air outlet is only a little cool, and the cooling effect is indeed poor. Open the cover and check that the electromagnetic clutch of the air conditioner compressor is repeatedly engaged and disconnected in a short time. From the failure phenomenon and the analysis of the usual maintenance experience, it can be basically judged that the reason for the non-cooling of this car is due to the repeated engagement and disconnection of the electromagnetic clutch of the compressor, and insufficient refrigerant circulation. What causes the electromagnetic clutch of the compressor to repeatedly engage and disconnect in a short time? Before detecting and finding fault points, we need to understand the working principle of this car's air conditioning system. The working principle diagram of this car's air conditioning system is shown in Figure 1.

This car is equipped with a dual-zone automatic temperature control system, which can be controlled in one or more positions. When the multi-function display (FDIM) touch screen or voice command is used and A/C is selected, the touch screen signal or voice signal is first transmitted to the SYNC module, and the SYNC module sends a request message to the gateway GWM through HS-CAN3. The gateway GWM then sends a request to the PCM via HS-CAN1. PCM controls the operation of the A/C clutch relay. At the same time, the gateway GWM will also send a request to the HVAC control module via MS-CAN. When the central control panel control module (FCIM) is used to turn on the air conditioner, FCIM sends this request signal to the PCM via the HS1-CAN through the gateway module GWM. The PCM controls the on and off of the air conditioner compressor clutch according to the input signals of various sensors. At the same time, the variable displacement solenoid valve is controlled by the duty cycle to achieve the purpose of controlling the displacement of the compressor to adapt to the refrigeration demand (this air conditioning system is equipped with a variable displacement compressor, and the PCM can control the compressor. The variable displacement solenoid valve works to complete the variable displacement of the compressor). PCM monitors the pressure of the high-pressure pipeline through the air-conditioning pressure sensor. When the pressure is too high or too low, the PCM will disconnect the compressor. After the PCM receives the request signal to turn on the air conditioner, if all the following conditions are met at the same time, the PCM will engage the compressor electromagnetic clutch: ①The PCM does not detect that the air conditioner pressure sensor value is too high or too low; ②The environmental visibility is higher than 0℃; ③

The evaporator temperature is higher than 1°C; ④The water temperature is lower than 118°C; ⑤There are no conditions such as full throttle opening. At the same time, PCM will send PWM signals to the compressor variable displacement adjustment solenoid valve according to the following input signals to control the variable displacement of the compressor: ①evaporator temperature; ②outdoor temperature; ③engine speed; ④vehicle speed; ⑤air-conditioning high-pressure pipeline Pressure; ⑥ intake air temperature, etc. In order to confirm the specific reasons for the repeated engagement and disconnection of the clutch, first check the vehicle systems with IDS, and there is no related fault code. At the same time, the outdoor temperature value displayed by the meter matches the current ambient temperature, and there is no abnormality. Then read the pressure value of the air-conditioning system as 0.75MPa without starting the compressor, and at the same time, the reading and the value of the data measured by the sweeping orometer are basically the same. Start the vehicle and turn on the air conditioner. When the compressor is disconnected, it is detected that the maximum pressure of the air conditioning system is only about 1.45MPa, as shown in Figure 2. After the above inspection, the problem of insufficient refrigerant in the system has been ruled out. At the same time, the reason why the PCM is repeatedly connected and disconnected due to the low or high pressure of the air-conditioning system has been eliminated.

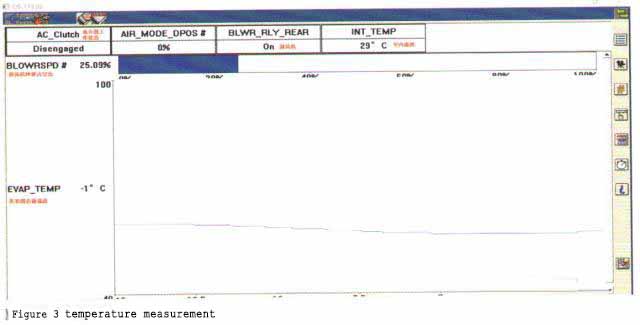

By reading the data of the engine, the engine water temperature is normal, and the throttle switch and engine load are consistent with the idling conditions. The possibility that the PCM cuts off the compressor due to excessive water temperature and excessive load is eliminated. Last read

The evaporator surface temperature sensor data is shown in Figure 3. From the data read,

The value of the evaporator surface temperature sensor has been rapidly changing back and forth from 5°C to -4°C, and the compressor clutch is also repeatedly engaged or disconnected.

That is, when the evaporator temperature sensor approaches 0°C, the compressor electromagnetic clutch is disengaged. When the temperature of the evaporator surface temperature sensor rises to about 4°C, the electromagnetic clutch is re-engaged, and the evaporator surface temperature value changes repeatedly in a short time. In order to find out whether the evaporator surface temperature sensor itself is faulty or the line is faulty or the air conditioning control panel is faulty, the evaporator surface temperature sensor plug is located at the upper right of the accelerator pedal. Query the circuit of the evaporator surface temperature sensor according to the circuit diagram, as shown in Figure 4. Check that there is no abnormality in the related circuit. Finally, use a multimeter to detect the resistance of the evaporator surface temperature sensor. During the inspection, it is found that this resistance will change rapidly. From the disconnection of the plug measurement, the resistance rapidly changes to infinity at 120k Ω as shown in Figure 5. So far, the cause of the fault has been found out, that is, the fault monitoring data of the evaporator surface temperature sensor itself is inaccurate, which causes the PCM to control the compressor electromagnetic clutch to repeatedly engage or disengage, which causes the vehicle to experience insufficient air conditioning and refrigeration. The fault is eliminated after replacing the new evaporator surface temperature sensor.

Fault summary: First of all, the fault of this car is the inaccurate monitoring data of the evaporator surface temperature sensor itself. The data detected by the sensor is -4~5℃, which is seriously inconsistent with the actual situation. The evaporator surface temperature sensor contains a thermistor, and the sensor can change its resistance with temperature. As the temperature rises, the resistance drops. As the temperature drops, the resistance rises. The evaporator surface temperature sensor is the input device of the HVAC control module, and the information is transmitted to the PCM through the MS-CAN. If the evaporator temperature is lower than about 1°C, the PCM will prohibit the compressor from working. PCM is based on the above control logic, so the value of the evaporator surface temperature sensor has been rapidly changing back and forth between -4°C and 5°C. At the same time, PCM also controls the compressor clutch to be repeatedly engaged or disconnected, resulting in insufficient cooling of the vehicle. Secondly, the approximate resistance of the evaporator surface temperature sensor with temperature changes is shown in the table. The values are for reference only, and differ for different models.