Video: Hot Air Circulation Tunnel Dryers: Structure, Working Principle, Features and Application

Figure 1: Tunnel dryer fan.

Tunnel dryer is a common drying equipment. It is widely used in food, medicine, chemical and other industries. It uses hot air circulation to transfer heat and evaporate the moisture in the product, thereby achieving a drying effect. Let's take a closer look at the structure and working principle of the tunnel dryer.

1. Tunnel Dryer Structure and Components

Tunnel dryers generally consist of an inlet and outlet, a hot air circulation system, a temperature control system, an air discharge system, etc.

1.1 Inlet and Outlet

The inlet and outlet are the entrance and exit of the tunnel dryer. Items that need to be dried can be put in through the entrance, and the dried items can be transferred to the exit using conveyor belts and other mechanisms. At the same time, the inlet and outlet can be flexibly adjusted to accommodate items of different sizes.

1.2 Hot Air Circulation System

The hot air circulation system includes fans, heaters, filters, etc. Its function is to heat, filter and purify the air and send it into the tunnel dryer inside to achieve heat transfer and moisture evaporation of items.

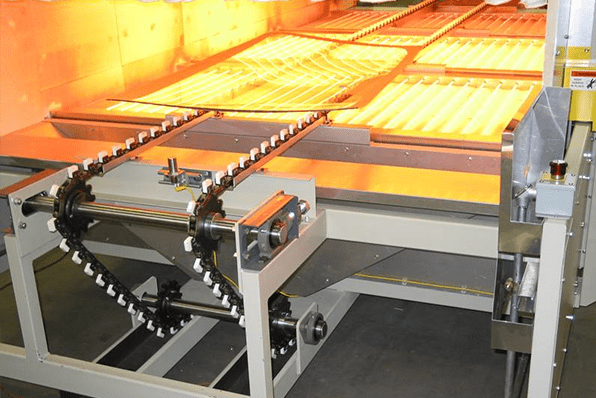

Figure 2: Tunnel dryer fan and motor.

1.3 Temperature Control System

The temperature control system is used to monitor the temperature and humidity in the oven and control the operation of the heater. Temperature controllers are generally used for real-time monitoring and control. At the same time, corresponding temperature and humidity alarm systems can also be set up to ensure personnel safety.

1.4 Air Discharge System

The air discharge system of the tunnel dryer mainly discharges hot air through the exhaust pipe to ensure the stability of the internal environment of the tunnel dryer. The exhaust system generally includes fans, dehumidifiers, regulating mechanisms and other parts.

2. Working Principle of Tunnel Dryer

Tunnel dryers work by circulating hot air to evaporate moisture from items. The specific process is as follows:

1. Place Items

Place the items at the entrance and they are slowly sent into the tunnel dryer by conveyor belts and other

mechanisms.

2. Create Hot Air

The air is heated by the heater to form high-temperature air.

3. Air Enters the Tunnel

The hot air enters the tunnel dryer through the circulating fan. During the drying process, hot air transfers heat

to the items being dried.

4. Evaporate Water

The moisture in the items is affected by heat. As the temperature rises, the water gradually evaporates, reducing

the moisture content in the items.

5. Discharge Hot Air

The evaporated moisture and hot air are discharged from the tunnel dryer through the fan after being processed by

the dehumidifier.

In short, the tunnel dryer heats items to make moisture evaporate by circulating hot air, drying items with high

moisture content. While drying, temperature and humidity control can also be used to ensure the stability of the

drying effect and the quality of the product.

Figure 3: Tunnel dryer machine.

3. Tunnel Dryer Features and Application

3.1 Advantages of Using Hot Air Circulation Tunnel Dryer to Dry Materials

Compared with the traditional natural air drying method, the hot air circulation has the following significant

advantages:

1. Stable temperature and humidity control: The hot air circulation tunnel dryer can accurately

adjust the temperature and humidity to ensure the quality and drying effect of the material during the drying

process and avoid over-drying or insufficient moisture.

2. Forced convection drying by circulating fan: The hot air circulation tunnel dryer uses a

circulating fan for forced convection drying to ensure that the surface of the material is evenly heated and avoids

uneven drying or caking problems that may occur in the traditional natural air drying method.

3. Fast and efficient drying effect: Due to the controllable temperature and humidity, the hot air

circulation tunnel dryer can achieve the ideal drying degree of materials in a short period of time and improve

production efficiency.

4. Safety, environmental protection and pollution-free: The inner and outer shell of the hot air

circulation tunnel dryer is usually made of food-grade 304 stainless steel, which is corrosion-resistant,

high-temperature resistant and does not cause any pollution to materials. At the same time, the material is easy to

clean, ensuring safety and environmental protection during use.

5. Meet the drying needs of different materials: Whether the materials are granular, flaky or

powdery, the hot air circulation tunnel dryer can adjust the drying time and temperature to the needed level to

achieve efficient and uniform drying.

Figure 4: Tunnel dryer machine.

Hot air circulation tunnel dryer, as an efficient and uniform drying equipment, is widely used in various industries. Its stable temperature and humidity control, forced convection drying, fast and efficient drying effect, and safety, environmental protection and pollution-free characteristics make it the first choice equipment for material drying.

3.2 Tunnel Dryer Application

There are many types of tunnel dryers, and the most commonly used type in industrial production is the air

circulation tunnel dryer. This kind of dryer is mainly composed of a fan and a heater, and uses air to do heat treat

for items.

Tunnel dryers are widely used in many industries. The following are some of the main applications of tunnel dryers.

Figure 5: Tunnel dryer machine on working.

1. Food Industry

Tunnel dryers are used in the food industry to dry noodles, instant noodles and other products. These products often

need to be dried and moisture removed in order to be stored and sold. A large amount of hot air flows during the

drying process to maintain the thermal effect and drying effect.

2. Textile Industry

In the textile industry, tunnel dryers are mainly used to dry printed and dyed fabrics. When fabric is printed and

dyed, moisture is added to the fibers. Drying printed and dyed fabrics improves their quality and reliability.

3.Pharmaceutical Industry

In the pharmaceutical industry, tunnel dryers are commonly used to dry pharmaceutical products. Pharmaceuticals need

to be stored in a dry environment to maintain their specific chemical properties. Complete removal of moisture from

the pharmaceutical product is key to achieving this.

4. Paper Industry

In the paper industry, tunnel dryers are mainly used to dry paper products. The papermaking process requires water

to be removed from the pulp, and tunnel dryers dry the paper, increasing production efficiency and reducing waste.

Overall, tunnel ovens play a key role in many industries, making drying items more efficient. If you are considering

using a tunnel dryer in your production, you should consider the drying speed your materials require and the size of

the items to choose the appropriate one.