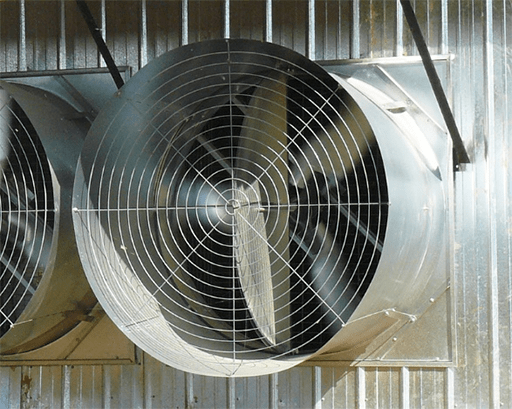

Figure 1: Galvanized Tunnel Fans.

Industrial fans can effectively control the air circulation in industrial production workshops. However, industrial fans can also fail due to improper use and prolonged use. This article will introduce the common failures, fault diagnosis methods and maintenance methods of industrial fans.

Common Industrial Fan Failures

To prevent and fix industrial fan failures, it is necessary to learn about some common types of failures:

1. According to the causes:

Deterioration failures: the parts will experience irreversible changes such as wear, fatigue, corrosion under the influence of various factors during use.

Artificial failures: due to poor management. For example, the power supply being cut off suddenly, the fan stops working.

2. According to the nature of the failures:

Intermittent failures: some functions are lost in a short time, and can be recovered after a little repair, such as control box code error, overload, etc.

Permanent failures: some parts are damaged and need to be replaced or repaired. For example, if the motor burns out, it needs to be replaced or repaired before use.

3. According to the law of failure occurrence:

Random failures: irregular and unpredictable failures

Regular failures: industrial fan failures occur at predictable intervals.

How to Judge the Failure Types?

Figure 2: Adjusting an industrial fan by hand.

Industrial fan failures vary widely. It is necessary to use fault diagnosis technology to monitor and diagnose the fan, i.e., to judge whether the mechanical equipment is running abnormally according to various information generated during the operation of the equipment. There are roughly two ways:

1. By experience:

Maintenance personnel can judge the failure of the fan by sight, hearing or touch according to their own experience. Fans generate noise and vibration during operation. By analyzing noise and vibration, the status of the fan can be effectively identified. The wear state of parts, such as bearings, can also be judged based on wear residues.

2. With the help of instruments

This is a more scientific method of judgment. It can be done with the help of sensors and computers. With the sensor as the input element and the computer as the output element for processing and analysis, a complete system is formed to detect whether each component is in good condition.

How to Fix the Failures?

There are different maintenance methods for different failures:

1. Overhaul

It is a complete maintenance of the entire fan. This requires disassembly, cleaning and inspection of all or most parts of the equipment and repairment of reference parts. After inspection, faulty parts and severely worn parts such as motor assembly, fan blade assembly, etc., will all be replaced, so that the performance can reach the standard of factory setting or normal working.

2. Item Repair

To repair a certain part of the fan to restore the original performance of the equipment, such as replacing a single fan blade.

3. Minor repairs

To replace the wearing parts and faulty parts that have reached the maintenance interval, clean the transmission system, replace the lubricating oil, and clean the lubrication system, etc.

4. Emergency repair

A small part of the large industrial fan is damaged, making the equipment to halt, which requires timely maintenance. For example, after the control box alarm is activated, the speed is detected as overload and needs to be adjusted to restore the normal operation of the fan.

5. Equipment modification

The original equipment is improved with new technology, new structure and new material. The original deficiencies are overcome, with new functions added and accuracy and reliability improved. For example, one-key control and monitoring of all fans in large logistics bases are carried out to install intelligent control components and programs.

Figure 3: Clean the industrial fan: to maintain it.

In all, correct operation and fixing, regular maintenance and proper modification can make the industrial fan to function better.

Related Info

How to Make an Industrial Fan Quiet?Comparisons between the Electronic Expansion Valve and the Capillary Tube

6 Common Electric Motor Failures and Solutions

What is an Industrial Fan?

How to Install an Industrial Exhaust Fan?