Figure 1: An EdP differential pressure transmitter mounted across a pump.

In order to prolong the service life of the pressure transmitter and reduce the error, regular inspection and maintenance are recommended, such as weekly inspection. The specific maintenance methods are as follows:

1. Keep it Dry

While the transmitter's circuitry is designed to withstand harsh extrusion processing environments, most transmitters are not completely waterproof. Wet conditions are harmful to normal operation. Therefore, it is necessary to ensure that the water in the water cooling device of the extruder barrel does not leak, or it will adversely affect the transmitter. If the transmitter has to be exposed to water or moisture, choose a special transmitter that is extremely waterproof.

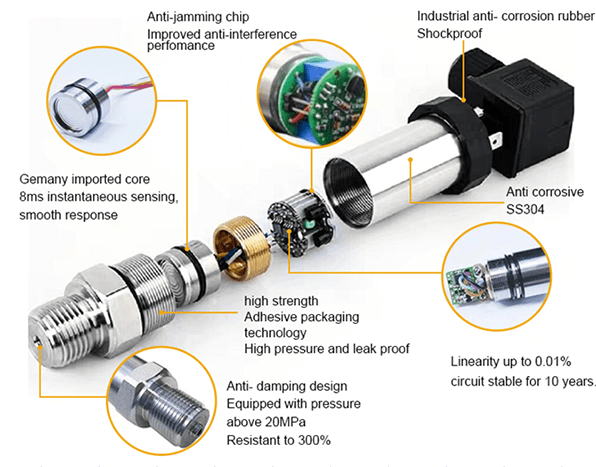

Figure 2: Components of the Meokon OEM 4-20mA anti-damping and -corrosion pressure transmitter.

2. Keep the Mounting Holes Clean

Keeping the mounting holes clean and preventing melt clogging are very important to ensure the normal operation of the equipment. Before the extruder is cleaned, all pressure transmitters should be removed from the barrel to avoid damage. When removing the transmitter, it is possible for melt residues to flow into the mounting holes and harden, which can cause damage to the top of the transmitter when the it is re-installed.

Cleaning kits can remove these melt residues. However, repeated cleaning processes have the potential to deepen damage to the transmitter from the mounting holes. If this happens, the transmitter should be raised in the mounting hole.

3. Choose the Right Location

When the pressure transmitter is installed too close to the upstream of the production line, unmelted material can wear down the top of the transmitter.

If the transmitter is mounted too far back, a stagnant zone of molten material may be created between the transmitter and the screw stroke, where the molten material may degrade and the pressure signal may be transmitted distorted.

If the transmitter is too deep into the barrel, it is possible for the screw to touch the top of the transmitter during rotation and damage it.

Generally, the transmitter can be located on the barrel in front of the filter screen, before and after the melt pump, or in the mold.

4. Clean Carefully

All transmitters should be removed before cleaning the extruder barrel with a wire brush or special compound, as both cleaning methods may damage the transmitter's diaphragm. When the barrel is heated, the transmitter should also be removed and the top of it should be wiped with a soft, non-abrasive cloth. At the same time, the hole of the transmitter also needs to be cleaned with a clean drill and guide bush.

Figure 3: A sample of an extruder barrel.

Related Info

The Differences between Solenoid Valves and Motorized ValvesChoose the Right Solenoid Valve

How to Deal with Spindle Amplifier Alarm Codes?

What is a Pressure Transmitter?

10 Things to Consider when Choosing a Pressure Transmitter