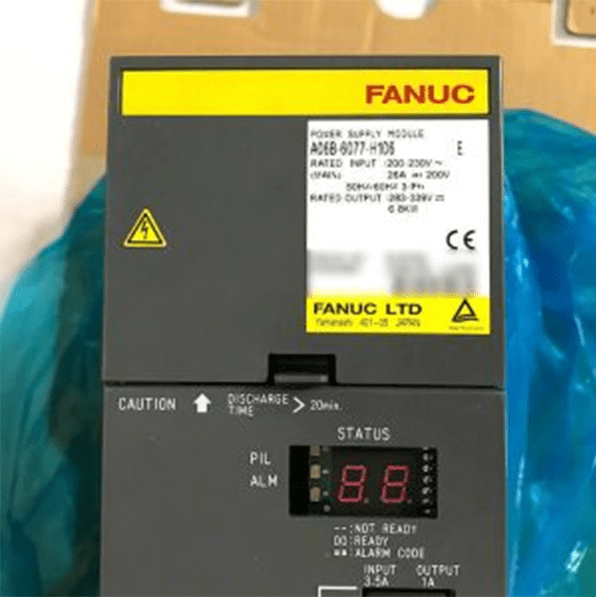

Figure 1: Fanuc S-Series Spindle Amplifier Module.

When faults occur, there will be various alarm codes on the Spindle amplifier, each representing different faults. This article will introduce some common codes, what they stand for and how to deal with the faults.

1. SP9001 Motor Overheating

Code: 01

Fault: The software detects that the spindle motor is overheated.

Troubleshoot:

1) Check the spindle motor temperature. If the temperature is normal, check the temperature sensor.

2) Check whether the cooling fan is abnormal.

3) Check whether the spindle is under high load (exceeding the rated value) for a long time.

2. SP9002 The Speed Deviation is Too Large.

Code: 02

Cause: The feedback speed of the spindle cannot follow the command speed of the spindle.

Troubleshoot:

1) Determine whether the load is too large. It will make the spindle unable to follow the commanded speed.

2) Check whether the initialization parameters of the spindle motor are abnormal.

3) Check whether the spindle motor amplifier and spindle motor are abnormal.

4) Modify parameter P4082.

Figure 2: Alarm code display on a spindle amplifier.

3. SP9003 Fuse Blown

Code: 03

Cause: The DC link fuse inside the spindle amplifier is blown.

Troubleshoot: Check for hardware damage.

1) Check the peripheral wiring circuit, especially the power cord.

2) Replace the spindle motor amplifier.

3) Check the motor insulation state.

4. SP9004 Power Supply Phase Loss/Fuse Blown

Code: 04

Cause: Phase loss of common power supply is detected.

Troubleshoot:

1) Confirm the condition of the input interface of the power wire.

2) Check the wiring of the CX48 interface.

3) As for high and low winding motors, check for the winding switch.

Figure 3: Different types of fuses.

5. SP9006 Thermal Relay Disconnected

Code: 06

Cause: The motor temperature sensor is disconnected.

Troubleshoot:

1) Re-initialize the spindle motor parameters, pay attention to the encoder parameters.

2) Check the spindle motor feedback line.

3) Check the spindle motor temperature sensor.

6. SP9007 Overspeed

Code: 07

Cause: The motor speed exceeds 115% of the rotary speed.

Troubleshoot:

1) Check the initialization parameters of the spindle motor.

2) Check the phase sequence of the spindle power line.

3) Check the spindle motor amplifier.

7. SP9009 Main Circuit Overheating

Code: 09

Cause: The temperature of the heat sink for cooling power semiconductors has risen abnormally.

Troubleshoot:

1) Improve the cooling capacity of the cooling device.

2) Check the external radiator cooling fan.

3) Replace the spindle amplifier.

Figure 4: Overheat circuit board.

8. SP9010 Low Input Power Supply Voltage

Code: 10

Cause: The input power supply voltage of the spindle amplifier is low.

Troubleshoot:

1) Check amplifier input supply voltage.

2) Replace the power input cable and replace the amplifier.

9. SP9011 DC LINK Overvoltage

Code: 11

Cause: When the spindle motor rotates at high speed, the inertia is large. Therefore, when the power supply of the motor is cut off, the regenerative braking function of the spindle does not work, so that the spindle motor cannot stop immediately, but coasts at stall until it stops.

Troubleshoot:

1) The overvoltage of the DC LINK part was detected on the common power supply (common power supply alarm display 7). Check the input voltage.

2) If the selection of the common power supply is wrong (exceeds the maximum output specification of the common power supply), contact the maintenance personnel to recalculate whether the selection of the power module is correct.

3) Confirm whether the spindle initialization parameters are normal, and try to modify the parameter P4672 at the same time.

4) Replace the amplifier.

Related Info

The Differences between Solenoid Valves and Motorized ValvesChoose the Right Solenoid Valve

What is a Variable Valve Timing Solenoid?

How does Variable Valve Timing Work?

What is Variable Valve Timing?