How to protect the refrigeration compressor, you must master the following knowledge! How to protect the refrigeration compressor, you must master the following knowledge! Why should the compressor be protected? ? When the compressor is running, some abnormal conditions may occur, such as: exhaust pressure is too high, suction pressure is too low, oil pressure is insufficient, motor is overheated, excess liquid enters the cylinder, etc. In the event of an abnormal situation, the compressor will be damaged if there is no protective measure. The protective measures taken on compressors can be divided into four categories: 1. Prevent liquid shock; 2. Pressure protection; 3. Protection of built-in motor; 4.Temperature protection.

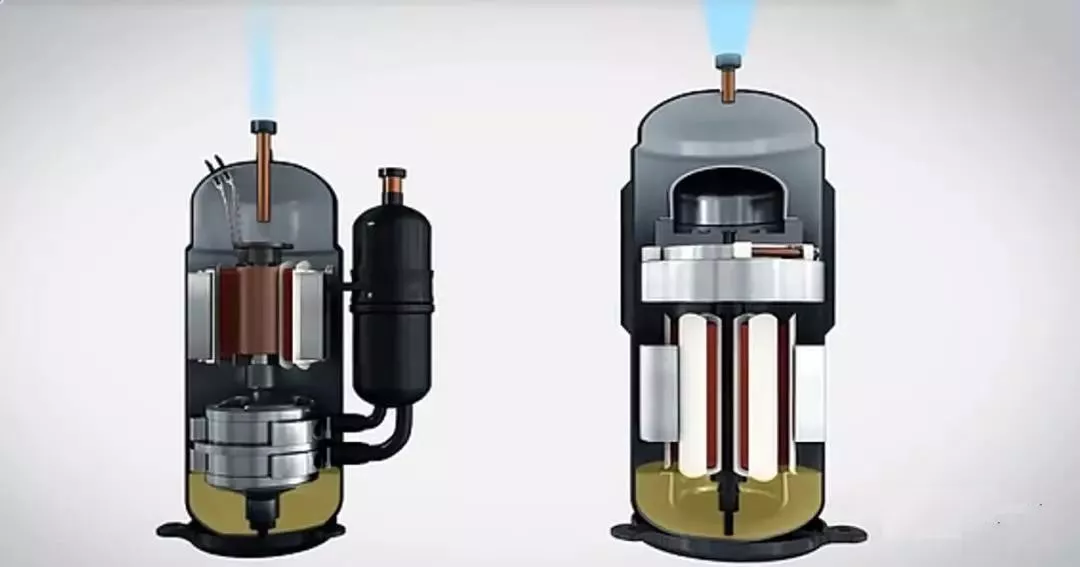

Prevent liquid shock When too much liquid enters the cylinder to be discharged from the exhaust valve, liquid hammer will occur in the cylinder. The high pressure generated during the liquid hammer damages the cylinder, piston, connecting rod, etc., so it is necessary to take measures Series of protection measures. 1. Fake cover The air valve assembly is tightly pressed on the end of the cylinder with a spring to form a false cover. When the pressure in the cylinder is too high, the exhaust valve is lifted, the liquid is discharged, and the pressure in the cylinder drops rapidly. 2. Oil heater The lubricating oil in the crankcase has refrigerant dissolved in it, and the dissolved amount increases when the ambient temperature is low. When the compressor starts, the pressure in the crankcase suddenly drops, a large amount of refrigerant vaporizes, and the lubricating oil is foamed and sucked into the cylinder, causing liquid shock. Using an oil heater to heat the lubricating oil before starting to reduce the amount of refrigerant dissolved in the lubricating oil is an effective measure to avoid liquid hammer. 3. Gas-liquid separator The gas-liquid separator shown is also called a liquid reservoir. The gas-liquid mixture from the evaporator is separated in the gas-liquid separator, and the gas enters from the upper part of the outlet pipe and flows out from the lower part. The separated liquid volume is stored at the bottom of the separator, the liquid refrigerant in it is heated and vaporized into the upper part of the outlet pipe, and the lubricating oil that cannot be vaporized flows into the outlet pipe from the return hole and then enters the compressor. Pressure protection 1. Control of suction and exhaust pressure When the compressor is running, due to the system or the compressor itself, the discharge pressure may be too high or the suction pressure may be too low. For this reason, it is necessary to control the suction and discharge pressure. Common controllers are not high and low pressure controllers, which are composed of a high pressure control part and a low pressure control part. When the discharge pressure exceeds a given value, the high-pressure control part will act to cut off the compressor power supply and stop it; when the suction pressure is lower than the given value, the low-pressure control part will act and cut off the compressor power supply and stop it. The compressor shuts down; an audible and visual alarm signal will be issued at the same time. 2. Safety valve To prevent the refrigerant from leaking to the atmosphere, a closed safety valve is adopted. The upper side of the valve disc bears the exhaust pressure, and the lower side bears the suction pressure and the elastic force of the spring. When the exhaust pressure is too high, the valve disc moves downward to open the side hole at the lower part of the valve seat, and the high-pressure gas flows into the suction chamber through this side hole and the side hole on the valve body. When the exhaust pressure is lower than the specified value, the valve disc will move upward under the action of the suction pressure and the elastic force of the spring to close the exhaust pipe. The opening pressure of the safety valve is adjusted with bolts. 3. Safety film Install a safety diaphragm between the suction and exhaust cavities. When the suction and discharge pressure difference exceeds the specified value, the diaphragm ruptures and the discharge pressure drops. The filter screen is used to capture the broken diaphragm to protect the compressor. 4. Lubricating oil pressure difference controller The difference between the oil pressure at the outlet of the oil pump and the oil pressure in the crankcase. In order to protect the good lubrication of the moving parts of the compressor, and to ensure the normal operation of some compressor air delivery control mechanisms (such as: hydraulic-pull rod control mechanism), the low pressure inlet and high pressure outlet on the controller must be connected. Built-in motor protection 1. Overheating The internal temperature of a well-designed motor that runs under specified conditions will not exceed the allowable value. However, when the motor is running at too high or too low a voltage, or in a high-temperature environment, the internal temperature of the motor exceeds the allowable value and starts frequently When the starting current is too high, the temperature will be too high. In order to overheat the motor, in addition to correct use and maintenance, an overheating relay can also be installed. The overheat relay can be installed inside the winding, called a built-in temperature relay, or installed outside the motor, called an external temperature-current relay. When the internal temperature of the motor exceeds the specified value, the bimetal with the built-in temperature relay deforms and causes the contacts to trip and the motor stops. When the temperature in the motor drops below the specified value, the contact is reset and the circuit is reconnected. External temperature-current relay: a disc-shaped bimetallic piece and a heater are connected in series between the two terminals. When the current in the motor is too large, the heating of the bimetallic sheet by the heater makes it at the position of the dotted line in the figure, the contact jumps and the motor stops rotating. The external temperature-current relay protects the motor and prevents it from overheating due to excessive current. However, in some occasions, the overheating of the motor is not caused by the excessive current, but because the low-temperature gas flowing through the motor is not enough. For example, because the refrigeration system is blocked, the refrigerant circulation is very small, and the motor cooling is extremely poor, resulting in internal overheating. The temperature relay plays the role of protecting the motor at this time. 2. Lack of phase The lack of phase of the three-phase motor will cause the motor to fail to start or overload. In order to protect the motor from being damaged by lack of phase, an overload relay is used, which is composed of a mechanical moving part and an electromagnetic switch part. The mechanical movement part has four terminals, two on the top and two on the bottom. A heater is installed between the upper and lower terminals. When the phase is missing, the overload current of the windings of other phases will flow through the heater. The bimetallic disc is heated and deformed, pushing the pressure plate, and then causing the overload relay contact on the electromagnetic switch to trip. There is no current in the excitation coil and the magnetic contactor is no longer closed. The motor stops rotating. The overload relay is also used for normal three-phase motors to protect the motor when the current is too large. 3. Imbalance between phases Unbalanced voltage between phases causes unbalanced current in three phases. In the phase with the largest current, the increase in temperature rise is approximately twice the square of the voltage imbalance ratio. For example: 3% voltage imbalance produces about 18% temperature rise. The measures to protect the motor from being unbalanced between phases are the same as those taken when the phase is missing. Temperature protection The temperature mentioned here refers to the exhaust temperature and the case temperature. 1. Exhaust temperature Excessive exhaust temperature can cause refrigerant decomposition, aging of insulating materials, carbonization of lubricating oil, damage to air valves, and clogging of capillary tubes and filter driers. The main protection method is to use a thermostat to sense the exhaust temperature. The thermostat should be placed near the exhaust port. When the exhaust temperature is too high, the thermostat will act and cut off the circuit. If the exhaust temperature is too high due to the hot gas bypass, the shutdown method should not be used, and the spray cooling should be used. 2. Case temperature The temperature of the casing will affect the life of the compressor. Excessive temperature of the cabinet may be caused by insufficient heat exchange capacity of the condenser. Therefore, check the scenery or water volume of the condenser and whether the water temperature is appropriate. If air or other non-condensable gases are mixed in the refrigeration system, the condensation pressure will increase. Overheating; if the suction temperature is too high, the casing is prone to overheating. In addition, overheating of the motor will also overheat the casing. To avoid overheating of the cabinet, the fundamental way to protect the compressor is to correctly handle the above-mentioned problems and install a temperature protector on the cabinet. The most commonly used external temperature-current protector of the case temperature protector. Place it in a suitable place on the casing. When the casing temperature is too high, the dish-shaped bimetal will deform due to the temperature, causing the contacts in the circuit to open and the compressor to stop.