How to use common refrigeration tools

1. Pressure gauge operation method:

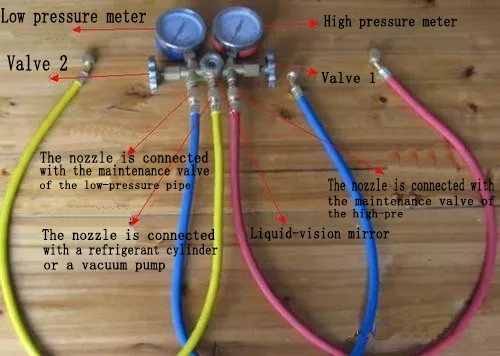

Generally, in the refrigeration industry nowadays, a compound double meter is used to measure the pressure of the refrigeration system, charge refrigerant, and vacuum, etc. It is widely used. The connection of this meter is shown in the figure below.

Pressure unit value conversion:

For the convenience of calculation in engineering technology, the atmospheric pressure value is used as 1kg/㎝². In refrigeration technology, megapascals (Mpa) are often used as the unit. There are two circles on the dial of our pressure gauge. Numerical scale value indicates two pressure values. One is the English system (expressed in psi), and the other is the international system of units (expressed in 1kg/㎝²).

The relationship between them is: 1kg/㎝²=9.8×10Pa=0.1 Mpa ≈ 1Kg ≈14psi

2. The air conditioning pressure test and the process of adding refrigerant.

(1) Air conditioning pressure test:

The air conditioner has two process ports for testing pressure, high and low pressure. These two process ports correspond to the high and low pressure gauge ports of the pressure gauge. {The pressure gauge blue gauge tube (low pressure gauge/vacuum gauge) is connected to the large pipe process port of the air conditioner (Low pressure pipe); the red gauge pipe (high pressure gauge) of the pressure gauge is connected to the small pipe process port of the air conditioner (high pressure pipe)}, after the connection is completed, wait for the air conditioner compressor to start, check the pressure change of the pressure gauge, the low pressure pressure is 5~6kg ( 70~85psi) The high pressure is normal at 16~20kg (225~285 psi). If the pressure is too low, it means there is less refrigerant, and if the pressure is too high, it means the refrigerant is overcharged. (2) The process of adding refrigerant:

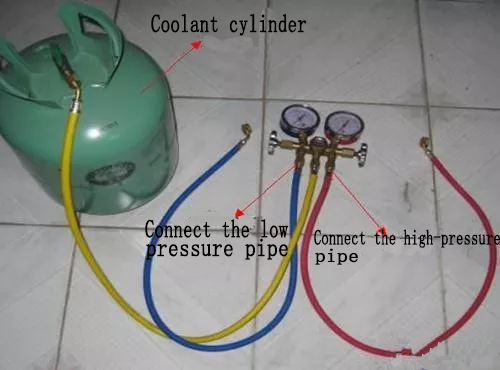

When the air conditioner is charged with refrigerant, connect the high and low pressure ports of the pressure gauge to the high and low pressure process ports of the air conditioner, and connect a fluoride tube to the refrigerant cylinder at the middle nozzle of the pressure gauge; then open the high and low pressure valve of the pressure gauge and twist slightly Loosen the valve of the refrigerant cylinder and use the cylinder's own refrigerant pressure to discharge the air in the pressure gauge tube. After the air-conditioning compressor is started, close the high-pressure valve (valve 1) of the pressure gauge and open the low-pressure valve (valve 2), and then fully open the valve of the cylinder, the refrigerant will be sucked into the air-conditioning refrigeration system as the compressor absorbs the pressure; Pay attention to the observation, when the low pressure reaches the normal value (normal value: 5~6kg (70~85psi), turn off the low pressure valve, and also close the switch of the refrigerant tank. Observe the pressure change and the cooling effect of the air conditioner for 30 minutes. Within the normal value, the air conditioner refrigeration is normal, and the filling of refrigerant is completed; finally shut down, quickly twist out the high and low pressure port of the pressure gauge, and tighten the high and low pressure process port of the air conditioner with a screw cap. Please see the picture

3.How to connect pipes to vacuum the refrigeration system?

As shown in the figure, the connection nozzle in the middle of the table is connected to the vacuum pump.

There are three ways to vacuum:

(1) Vacuum on one side of the low pressure, directly connect the blue gauge tube (low pressure gauge/vacuum gauge) of the pressure gauge to the large pipe process port (low pressure pipe) of the air conditioner, and then close the high pressure valve of the red gauge tube (high pressure gauge) ( Valve 1), then start the vacuum pump, then open the low-pressure valve (valve 2) for vacuuming, pay attention to the change of the pointer of the low-pressure pressure gauge,

(2) Generally, pump for 30 minutes or the pointer is at -0.06Mpa, close the valve of the low pressure meter, and cut off the power supply of the vacuum pump.

(3) High and low pressure double-sided vacuuming is to connect pipes to the process ports on the high and low pressure pipes of the air conditioner and then vacuum.

(4) Duplex vacuuming is to vacuum the entire refrigeration system more than twice to obtain the ideal vacuum. After a vacuum, a certain degree of vacuum is maintained in the refrigeration system. At this time, close the valves of the high and low pressure meters, remove the vacuum pump and connect the refrigerant cylinder to fill the system with refrigerant (generally 1~2Kg is sufficient); start the compressor to run for a few minutes to make the remaining gas in the system and refrigerate Mix the agent, and then turn on the vacuum pump for a second vacuum. The evacuation time is at least 30 minutes. This can further reduce the gas in the system to achieve the specified vacuum. This method is better than single-sided vacuuming, but it will consume a certain amount of refrigerant and time. 4. Foreman tools and methods of use:

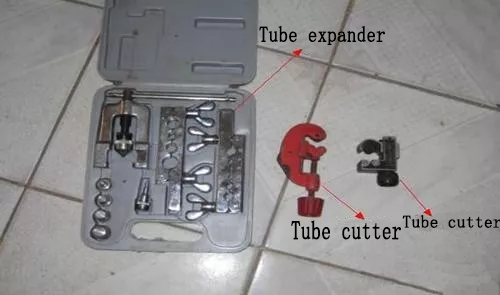

(1) Pipe cutter

The pipe cutter is also called a pipe cutter, which is a tool for cutting metal pipes such as copper pipes and aluminum pipes.

How to use the tube cutter: Place the copper tube between the roller and the cutting wheel, the side wall of the copper tube is close to the middle position of the two rollers, and the cut of the cutting wheel is clamped perpendicular to the copper tube. Then turn the adjusting handle to make the cutting edge of the cutter cut into the wall of the copper tube and then evenly rotate the cutter around the copper tube as a whole. As shown below:

(2) Expander

The tube expander is also called the tube expander. It is mainly used to make the bell mouth and cylindrical mouth of the copper pipe. The clamp of the expander is divided into two symmetrical halves. One end of the clamp is connected with a pin, and the other end is fastened with a fastening nut and bolt. The holes formed after the two halves are aligned are made into threaded shapes according to different pipe diameters, in order to facilitate tighter clamping of the copper pipe.

How to use the pipe expander: When expanding the pipe, first flatten the flared end of the copper pipe with a file, then place the copper pipe in the fixture hole of the corresponding pipe diameter, and tighten the fastening nut on the fixture to secure the copper pipe Clamped, the specific flaring operation method is as follows:

5. Brazing (oxygen welding)

Brazing is also called oxygen welding, and the welding tool required is a welding gun (torch). The welding equipment required includes oxygen cylinders, acetylene gas cylinders (or liquefied petroleum gas cylinders), connecting hoses and decompression gauges, etc. The solder used is copper-phosphorus alloy electrode (copper electrode). For the welding of refrigeration pipes, we generally use brazing, which means that the high temperature flame generated when combustible gas (liquefied petroleum gas) and combustion-supporting gas (acetylene) are mixed in the torch is used to heat the material to be welded and melt the solder to make it It becomes the filler metal of the gap and connects the weldments. This welding method is called brazing.

Operating method of welding gun:

First turn on the valve switch of the acetylene cylinder, then open the valve switch of the oxygen cylinder, then slowly loosen the acetylene valve at the welding torch so that acetylene gas is discharged from the welding nozzle (note: remember not to open too large), and then use a lighter to light the welding The nozzle makes the acetylene gas burn, then slowly open the oxygen valve of the welding torch (valve 1 or valve 2 is fine), adjust the flame! Before welding, clean the welding joint and preheat the welding joint or pipeline. When the color of the copper pipe is dark red, immediately place the welding rod on the welding place and continue heating until the welding rod is fully melted and flows to the gap and is firmly attached When on the pipe, remove the flame and the welding is complete. Then first close the oxygen valve of the welding torch, then close the acetylene valve, and finally close the oxygen and acetylene cylinder valves. Pay special attention to the preheating time when welding the interface between the capillary and the filter drier. The shorter the welding time, the better to prevent the capillary from overheating and melting. The oxygen bridge is a tool provided when a large bottle of oxygen is added to a small bottle.

6. Multimeter:

Multimeter is also called multimeter or universal meter. It is a kind of direct-reading instrument with multiple uses and multiple ranges that is extremely widely used. It is divided into pointer multimeter and digital multimeter.

A general multimeter can measure DC current, DC voltage, AC voltage and resistance. At present, the most widely used digital multimeter is the advantages of high measurement accuracy, high input impedance, intuitive display, accurate reading, complete functions, small size and easy to carry. In terms of display sensitivity, digital multimeters are divided into four digits and five digits.

Digital multimeters can measure power: DC voltage, DC current, AC voltage, AC current, resistance, capacitance, diode forward voltage drop, transistor DC amplification, etc. Some meters also have AC and DC high current (10A) measurements. The first gear also has the functions of automatic zero adjustment and polarity display, over-range and low battery voltage display functions.

Clamp ammeter:

Clamp-on ammeter is also called card meter, used to measure AC current.

Precautions for using clamp ammeter:

1) In order to make the reading accurate, the two surfaces of the jaws should be tightly closed

2) When performing current measurement, the position of the current-carrying wire under test should be placed in the middle of the jaws to avoid errors.

3) Before measurement, you should estimate the value range of the current to be measured, select a suitable range, or select a larger range for measurement, and then select an appropriate range based on the current.

4) If you want to measure a small current, you can wind the wire around the clamp-shaped iron core a few times. At this time, the pointer stays at the value of the larger current. Dividing the measured current value by the number of turns of the wire wound on the clamp core is the current value of the wire.

Picture: Clamp-on Ammeter)

Use a multimeter to measure the resistance of the three function leg coils (CS, RS, CR) of the compressor separately. There should be no open circuit or short circuit, and no short circuit to the ground. As shown in the figure below: