For a hydraulic system, which uses hydraulic oil as the medium to transmit power and energy, oil leakage may occur during its work process. Once this problem is not properly handled, it will not only affect the working performance of the system and damage the hydraulic components, but also waste resources and cause a certain degree of pollution to the environment. In serious cases, it may cause accidental injury to the operator.

For this reason, it is very important for operators of hydraulic system-related equipment to master certain leakage repair skills. This article will analyze the causes and solutions of hydraulic system oil leakage to help readers better understand and deal with this problem.

1. Oil Leakage in Hydraulic Systems

Oil leakage in the hydraulic system can be divided into internal leakage and external leakage.

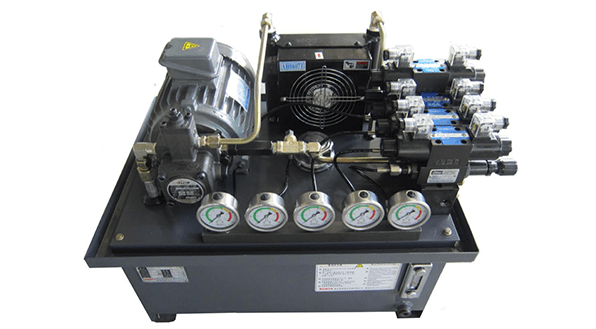

External leakage mainly refers to the leakage of hydraulic oil from the system into the environment, which occurs outside the hydraulic pipelines, hydraulic valves (hydraulic solenoid valves), hydraulic cylinders and hydraulic pumps (hydraulic motors) of the hydraulic system.

Internal leakage refers to the hydraulic oil flow from the high-pressure side to the low-pressure side within the system due to the existence of the pressure difference between the two sides and the failure of seals. For example, in the hydraulic system, oil leaks from the high-pressure chamber to the low-pressure chamber, or from the pressure channel in the directional control solenoid valve to the oil return channel, etc.

2. Four Major Hazards of Oil Leakage in Hydraulic Systems

(1) Equipment efficiency drops significantly and energy loss gradually increases;

(2) The reliability of equipment operation decreases;

(3) It will cause related products (especially light textiles and food) and environmental pollution;

(4) Due to poor sealing, external contaminants are more likely to invade, causing a vicious cycle, and early wear and tear of system components. In severe cases, the entire machine may be paralyzed.

3. Causes of Hydraulic System Oil Leaks

The reasons for oil leakage in hydraulic systems are various and complex. The following is mainly analyzed from the aspects of seal leakage, contaminated hydraulic oil , component tolerance, oil temperature rise, and hydraulic shock.

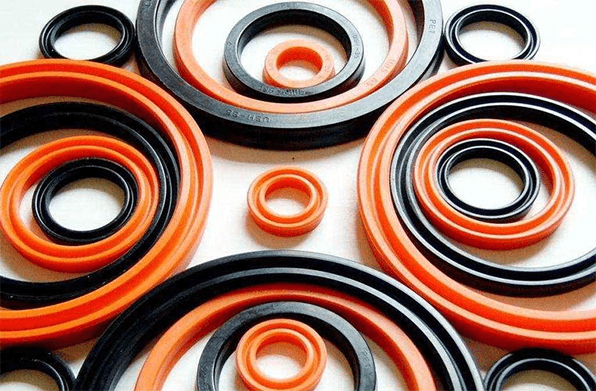

3.1 Seal Leakage

In hydraulic systems, seals are the first thing that comes to mind when leaks happen. The main reasons for seal leakage are as follows:

① Problem with the quality of the seal. The material of the seal is of inferior quality, its manufacturing process and precision do not meet the requirements.

② Unreasonable selection of seals. The selected seal cannot meet the requirements of working pressure, working speed and temperature, or the selected seal type is improper.

③ The installation groove of the seal is improperly designed, the temperature and humidity of the seal are improper during storage, and it is corroded and deteriorated by oxygen and ozone.

3.2 Contaminated Oil

Oil contamination is mainly caused by gas, water invasion, etc.

① Gas invasion: Under atmospheric pressure, about 10% of air can be dissolved in hydraulic oil. In hydraulic systems under high pressure, more air or gas will be dissolved in the oil. In addition, if the surface of the hydraulic system components is dented or damaged, it is very easy to cause cavitation, which will cause the surface of the hydraulic components to wear and cause leakage.

②Water invasion: Due to the influence of factors such as humid working environment, water may enter the hydraulic systems. It will react with the hydraulic oil to form acidic substances and sludge, which will reduce the lubrication performance of the hydraulic oil and accelerate the wear of components. It can also cause the stem of the control valve to stick, making it difficult to operate the control valve, scratching the seal and causing leakage.

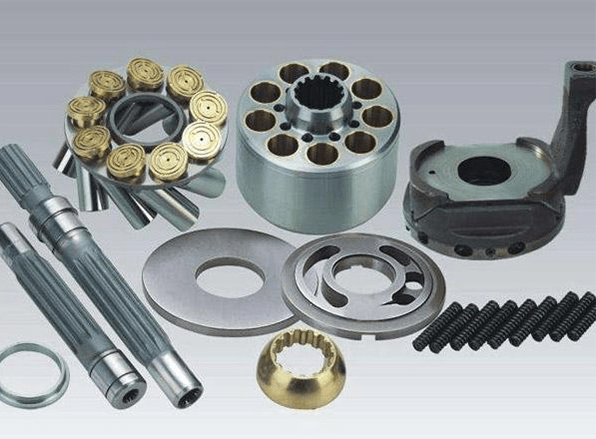

3.3 Component Manufacturing and Assembly Accuracy is Out of Tolerance

All hydraulic components have strict dimensional tolerances, geometric tolerances and other requirements. If they are out of tolerance during the manufacturing process, the seals will be deformed, scratched, etc. and lose their sealing function.

All these will lead to system leakage, including rough system assembly, lack of vibration reduction and isolation measures, over-pressure use of the system, failure to perform timely inspections of the system as required, and failure to replace consumable parts in time when their life span has expired.

3.4 Too High Oil Temperature Rise

When the hydraulic system is working, the oil temperature must be controlled. If it is too high, the following phenomena will occur:

① In most cases, when the oil temperature often exceeds 60°C, the oil viscosity drops significantly, the lubricating oil film becomes thinner, the friction increases, and the wear increases. Besides, the sealing ring may expand, age, and fail, eventually causing leakage in the hydraulic system.

② After the oil temperature rises, the volume expands and the pressure rises. The oil leakage increases as the pressure increases, thereby increasing the leakage.

3.5 Hydraulic Shock

Due to frequent direction changes in the hydraulic system, sudden starting of the oil pump or closing of the valve under relatively high pressure, and rapid movements of the cylinder body will cause instantaneous peak pressures up to several times the working pressure. Sometimes it is enough to damage sealing devices, pipes or other hydraulic components and cause leakage.

4. Solutions for Hydraulic System Oil Leakage

The factors causing the oil leakage of the hydraulic system of construction machinery are the result of the comprehensive influence of many aspects. With the existing technology and materials, it is difficult to fundamentally troubleshoot it.

Only based on the above factors that affect hydraulic system leakage, reasonable measures can be taken to minimize the leakage.

(1) In the design and processing steps, important factors affecting leakage should be fully considered, such as the design and processing of seals. In addition, the selection of seals is also very important. If the influencing factors of leakage are not fully considered initially, it will cause immeasurable losses in future production.

(2) In terms of hydraulic oil contamination control, we must find the source first, strengthen the control of it, and take effective filtering measures and conduct regular inspections of oil quality.

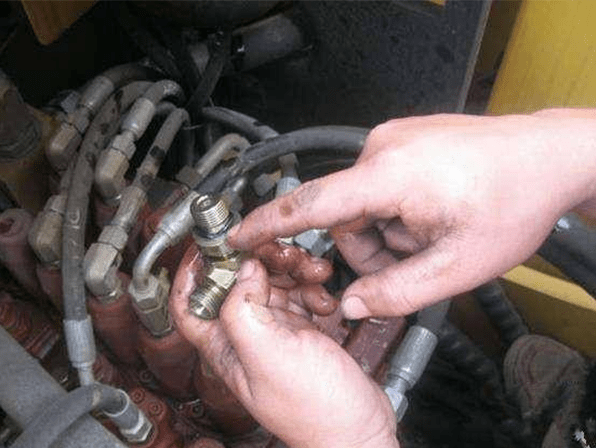

(3) Before assembling the hydraulic system, test the pressure resistance of the components, and check the contact surfaces of the components for leakage. If leakage occurs, take corresponding measures. When assembling hydraulic components and hydraulic systems, they must be strictly cleaned, deburred, and welded slag removed, and necessary anti-corrosion treatments must be carried out. They must be assembled in strict accordance with the assembly process requirements to eliminate gap distortion caused by assembly and gap abrasives formed by burrs, welding slag and rust.

(4) To reduce hydraulic shock, the commonly used methods are:

① Reduce the starting, stopping and direction change frequency of the system as much as possible;

② For hydraulic systems that require frequent direction changes, use a direction control valve with a damper as much as possible;

③ Set up an accumulator in front of the control valve to reduce the distance of shock wave propagation, thereby slowing down the hydraulic shock;

④ Increase the diameter of the pipe, shorten the length of it as much as possible or use rubber hose;

⑤ Setting up a safety valve can release the system pressure and reduce the pressure impact when it increases.