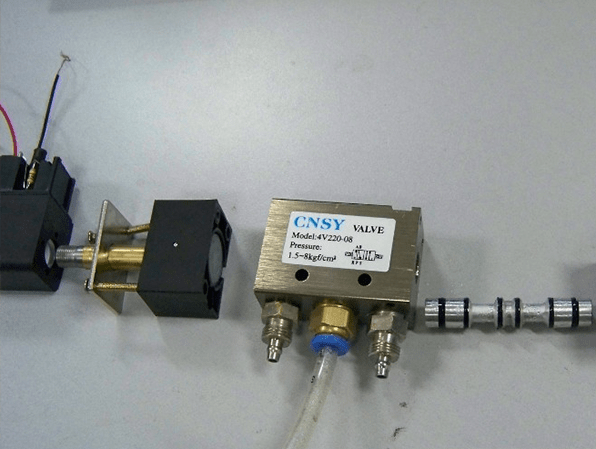

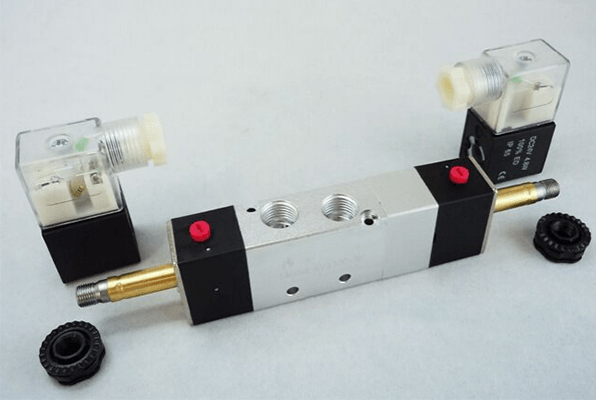

The pneumatic solenoid valve is a widely used control component, and various faults may occur during its practical applications. The following will introduce some common faults and corresponding solutions of pneumatic solenoid valves.

1. Troubleshooting Pneumatic Solenoid Valve Faults: Causes and Solutions

1.1 Air Leakage

Air leakage is one of the common failures of pneumatic solenoid valves, which often manifests as a drop in air pressure or insufficient air pressure.

Causes: Poor or aging sealing, loose connection, blocked air paths, damaged valve seats, etc.

Solutions: Check the air lines, reinstall fasteners, and replace seals or damaged valve seats.

1.2 Solenoid Coil Always Burned

Causes:

1. Poor wiring connection: Insecure wiring, loose connections, etc. will lead to unstable current, which will cause the solenoid valve coil to burn out.

2. Power supply overload: It means that the current/voltage output by the power supply exceeds the rated value. When it exceeds a certain range, it will cause the solenoid valve coil to burn out.

3. Environmental issues: If the solenoid valve coil often works in harsh environments, such as high temperature, humidity, vibration, etc., it will cause damage to its insulation layer and eventually lead to burnout.

Solutions:

1. Replace the solenoid valve coil: If the coil has been burned, the simplest solution is to replace it with a new one. However, it should be noted that when replacing the coil, you must choose the one that matches the brand, model and specification of the original solenoid valve to ensure its compatibility.

2. Check and repair the circuit: If the solenoid coil is not damaged but still does not work properly, then the circuit needs to be checked and repaired. First, you should check the power supply, fuse, wiring, etc. in the circuit to ensure that the circuit is normal. If the problem still cannot be solved, it is recommended to ask an electrical professional for inspection and repair.

1.3 Open Circuit of Solenoid Coil

Causes: The solenoid coil is aged, damaged or has poor contact.

Solutions: Replace the solenoid coil or re-connect the coil connector.

1.4 Stuck or Insensitive Solenoid Valve

Stuck valves are also a common failure in pneumatic solenoid valves. When the solenoid valve receives the signal to operate but the air cylinder does not move, it is often because the solenoid valve is stuck.

Causes: Poor coordination between the valve core and the valve hole, accumulation of dirt, etc.

Solutions:

1. Check the piston / valve core: Check whether the piston / valve core in the pneumatic solenoid valve is damaged, worn or stuck, and replace or repair them in time.

2. Check the quality of the air source: Check whether there is oil, water and other dirty substances in the air source. It is recommended to use a filter in the system for purification. Besides, clean or replace the valve core.

1.5 Too Noisy Pneumatic Solenoid Valve

Causes: It may be related to damage to the mechanical parts of the solenoid valve itself.

Solutions:

1. Check the air supply pressure: Check whether the air supply pressure of the pneumatic solenoid valve is lower than the rated pressure. If it is, it may cause increased noise, so raise the air supply pressure.

2. Check the status of the seals: Check whether the seals of the pneumatic solenoid valve are intact. If they are aged or worn, replace them in time to reduce air leakage and noise generation.

3. Add buffer devices: Add buffer devices at the air inlet and outlet of the pneumatic solenoid valve can reduce the noise generated when air flows.

1.6 High Temperature Fault

Pneumatic solenoid valves may overheat when used for a long time or in high temperature environments, which may cause damage to the pneumatic solenoid valve and affect its normal operation.

Solutions:

1. Check the working environment temperature: Check whether the temperature of the working environment of the pneumatic solenoid valve exceeds the rated operating temperature range. If it does, it is recommended to take cooling measures.

2. Check the air supply pressure: Check whether the air pressure in the air supply pipeline exceeds the maximum pressure. If it does, reduce the air supply pressure.

3. Check the cooling measures: Check whether the cooling measures of the pneumatic solenoid valve are in place, whether heat sinks are installed, etc.

1.7 Valve Unable to be Opened or Closed

Causes:

The valve core is clogged.

The valve parts are damaged.

The solenoid coil is faulty, etc.

Solutions:

Clean the valve core.

Replace damaged valve parts.

Check and replace the faulty solenoid coil.

1.8 Unstable Valve Operation

Causes: Spring failure, air path blockage, abnormal control signal, loose valve components, etc.

Solutions: Check and replace failed springs, clean impurities or blockages in the air path, check whether the control signal is normal, and tighten valve components to ensure stable working conditions.

2. Conclusion

The above are some common pneumatic solenoid valve failures and corresponding solutions. Understanding the causes and common faults of pneumatic solenoid valves and taking corresponding solutions can help ensure the normal operation and long-term stability of pneumatic solenoid valves. Regular maintenance is also key to extend the life of your pneumatic solenoid valve and improve system reliability.