Is the temperature difference between the inlet and outlet of the cold dryer the bigger the better

Since the refrigeration dryer removes water by cooling the compressed air, many users think that the lower the outlet air temperature of the refrigeration dryer, the better, or the greater the temperature difference between the inlet and outlet of the refrigeration dryer, the better. In fact, this is not the case. What?

To analyze this problem, we need to first look at the working principle of the cold dryer.

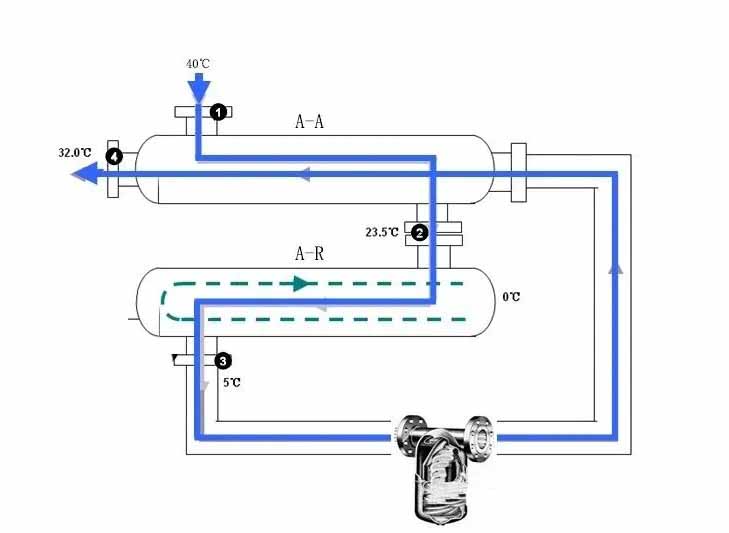

The following figure is an example. The saturated compressed air at 40°C has been cooled twice in the pre-cooler (AA) and the evaporator (AR), and finally becomes saturated air with a temperature of about 5°C. The corresponding pressure dew point is also That is 5°C. However, if there is no pre-cooler in the refrigeration dryer (or the area of the pre-cooler is too small), the dry air at about 5°C will be directly sent to the outlet of the refrigeration dryer. In this case, the finished product air sent by the refrigeration dryer is A state of low temperature and close to saturation;

If the pre-cooler is configured normally, the dry compressed air at about 5°C coming out of the evaporator will exchange heat with the moist intake air in the pre-cooler. After the heat exchange, the temperature of the dry air increases and the temperature of the wet air decreases; while the wet air cools down, part of the water vapor will be condensed and discharged. This heat exchange is entirely based on the cold energy carried by the low-temperature dry gas, thus saving the energy consumption of the refrigeration compressor. The dry gas can be warmed up during this heat exchange. As the temperature rises, its relative humidity gradually decreases. Assuming that the separator can fully separate and discharge the condensed water, then the absolute water content of the warmed dry gas does not change. In other words, the pressure dew point is 5°C.

In the above two cases, the product gas pressure dew point value of the refrigerated dryer is 5℃, but the outlet temperature of the refrigerated dryer is about 5℃ and the other is about 32℃. There is a big difference. It is not feasible to judge the water removal effect of the refrigeration dryer by the temperature of the air outlet of the machine.

In fact, the refrigeration dryer system equipped with a pre-cooler not only saves energy, but also effectively protects the gas pipeline. Although the moisture content of the compressed air from the evaporator is relatively low after dewatering, the relative humidity is 100%; the higher the relative humidity, the more likely it is to cause corrosion to the pipelines flowing through it. When the relative humidity is very low, the corrosion can be ignored; when the relative humidity gradually increases and reaches the critical relative humidity of the pipeline medium, the corrosion rate will rise sharply.

The critical relative humidity value of general steel is 50%~70%. By cleverly increasing the pre-cooler in the design of the refrigeration dryer, not only the load of the refrigeration dryer is effectively reduced, but also the outlet air temperature is returned to reduce its relative humidity to below 50%, thereby avoiding corrosion of the gas pipeline .

Therefore, in the use of the refrigeration dryer, there is no need to blindly pursue a low outlet temperature, but we need to pay attention to the value of the evaporation temperature (the dew point of the refrigeration dryer); on the basis of ensuring the evaporation temperature, the temperature difference between the inlet and the outlet of the refrigeration dryer The smaller the cooling capacity, the more fully utilized the cooling capacity and the lower the relative humidity of the outlet air; this not only saves energy, but also effectively protects the user's gas pipeline.

Newmantech: You get the guarantee of high-quality compressed air and gas

Newmantech was established in Kenosha, Wisconsin in the United States in 1966, dedicated to the production of compressed air drying and purification equipment. In the 1970s, a distribution network was established in the United States and introduced a series of blast, micro-heat and non-heat adsorption dryers. In the 1980s, the company began to expand its business to China to increase the market share and popularity of its products in the Chinese market. At the beginning of this century, the company expanded its production to the industrial nitrogen production and nitrogen tire inflation market. Joining Atlas Copco Group in 2005, the company has a bigger and faster breakthrough and development. We are more committed to research and development of high-tech products that meet the higher requirements of the market.