Market application and prospect analysis of air compressor waste heat recovery

Background With the rapid development of industry and economy, people's demand for energy is also increasing day by day. With the endless exploitation of human beings, the reserves of fossil fuels are decreasing day by day, and the world energy crisis is increasing day by day. Subsequently, the rational use of energy, the efficient use of energy, and the reuse and recycling of energy have attracted widespread attention. China is a populous country with relatively tight energy utilization. Faced with the inability of rapid development of energy production and the urgent need for rapid economic development, there are only two options available: one is to increase energy production as much as possible, and the other is to save energy. .

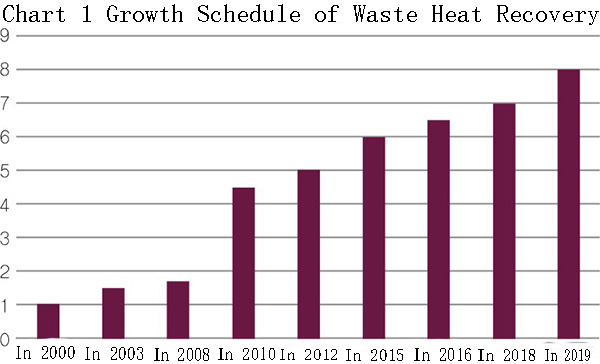

The recovery and utilization of industrial waste heat is an effective way to improve energy efficiency and environmental protection, and is of great significance for improving the development of the national economy, the secondary use of energy and the protection of the environment. Therefore, industrial waste heat recovery has received great attention in many provinces and industries.

Industrial waste heat refers to the heat released in the industrial production process (excess heat, remaining heat, wasted heat). Waste heat recovery is an energy-saving and environmentally friendly way to recover the heat through a certain technical device and get fully utilized. At present, waste heat recovery has been widely used in the market, such as flue gas waste heat recovery, air conditioning waste heat recovery, etc., which can save energy consumption and bring many conveniences for many enterprises and factories.

With the introduction of secondary energy recovery and utilization, air compressor waste heat recovery has also received more and more attention, and is currently widely used in textiles, coal mines, steel, power plants and other industries.

Air compressor waste heat recovery is of great significance

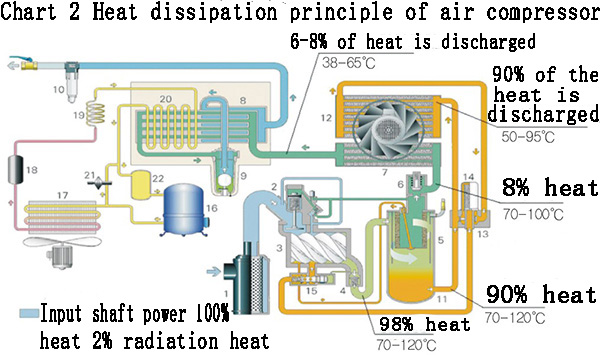

Air compressor is equipment that must be used by factories and enterprises. Air is a free resource bestowed by nature, but its compressed cost is quite expensive. Inhale air from the environment and discharge the high-pressure air after compression. This process not only increases the pressure potential energy of the air, but also generates a large amount of compression heat. According to statistics from the US Department of Energy, the electric energy consumed to increase the potential energy of the air only accounts for about 20% of the total electricity consumption. About 80% of the electric energy is converted into heat, which is equivalent to spending 10kW of electricity to obtain 2kW of aerodynamic energy. This heat has not been fully utilized in the past, but is directly discharged into the atmosphere through the heat dissipation system, which is not only not energy-saving but also environmentally friendly. The heat dissipation principle of the air compressor is shown in Chart 2.

The temperature of the oil and gas mixture discharged from the air compressor is generally as high as 80-100°C. If the heat of the air compressor cannot be released in time, it will cause serious damage to the equipment and affect the gas production efficiency. If it reaches the upper limit of oil temperature, it will shut down protectively. Therefore, air compressors are equipped with air-cooled or water-cooled systems for cooling, and this forced cooling process is actually a wasteful process. In fact, a large part of the wasted heat can be recycled. After installing the air compressor waste heat recovery device, most of the heat energy is fully utilized, which protects the environment and reduces the overall energy consumption of the factory. Through the air compressor waste heat recovery equipment, all the excess heat energy of the air compressor can be used, and the cold water can be converted into hot water of 45 degrees to 85 degrees. It is widely used in the production and life of enterprises, such as domestic hot water, hot air baking, heating supply, hot water for electroplating tank, supplementary hot water for boiler, water for cleaning equipment, etc.

According to the latest national "Boiler Air Pollutant Emission Standards" (GB13271-2014) and the State Council’s Air Pollution Prevention and Control Action Plan, coal-fired boilers must implement stricter emission standards from July 1, 2016, and in principle Small coal-fired boilers above 10t and below must be eliminated as soon as possible. Therefore, air compressor waste heat recovery has become a trend.

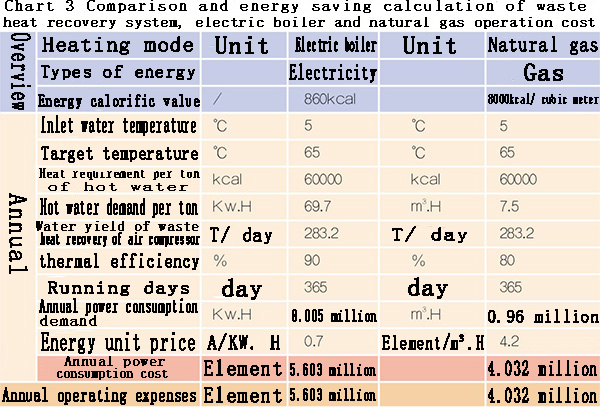

From the comparison of charts 3 and 4, it can be clearly seen that waste heat recovery not only allows companies to respond to national energy conservation and environmental protection policies, but also saves a lot of money for companies.

For enterprises, it is necessary to effectively analyze the design plan and economic benefits of the waste heat recovery air compressor in order to find an effective plan and give full play to the corresponding function of the waste heat recovery. Figure 5 shows the air compressor waste heat recovery market analysis.

Air compressor waste heat recovery unit

Based on this situation, a considerable number of enterprises have realized the recovery and utilization of heat energy by adjusting the heat exchange method. This transformation can not only recover energy to the maximum extent, reduce energy consumption, but also improve the gas production efficiency of air compressors and extend air Life of press equipment. In response to this situation, waste heat recovery equipment is slowly showing its advantages in the industry.

Air compressor waste heat recovery unit is a device that specializes in recycling and utilizing the high-temperature oil and gas heat energy generated during the operation of the air compressor to realize the collection and utilization of heat energy. As shown in the figure below, the motor drives the screw to rotate the air through the filter and is sucked into the screw compressor to form high-pressure air, which is mixed with the back and forth oil to form a high-temperature oil-gas mixture, which enters the oil-gas separator. The oil-gas mixture is divided into high-temperature oil and The high-pressure gas is supplied to the user after passing through the radiator, while the back and forth oil and gas are separated after the oil-gas separator, condensed into a liquid state, and then radiated by the cooler and filtered back to the compressor to complete a cycle process. The waste heat recovery machine introduces high-temperature return oil (or high-temperature oil and gas) into the waste heat recovery unit of the air compressor, and fully recovers the high-temperature heat generated during the operation of the air compressor through the heat exchanger, while effectively reducing the operating temperature of the air compressor Improve the effective operation of the air compressor and increase the gas production.

Because the internal circulation of the compressor requires oil temperature, and the heating value of different temperatures is different, the heat exchange efficiency of the heat exchanger is different. According to actual engineering experience, the heat that can be used is equivalent to the shaft power of the compressor. 65%, the double recovery efficiency of oil and gas can reach more than 80%. The recovery method is mainly through oil temperature (75℃-90℃) heat recovery, and air temperature (75℃-90℃) heat recovery as supplementary.

Heat prediction of air compressor waste heat recovery

For the heat analysis of an air compressor, take 1 132 as an example, the air compressor is loaded at 80%, calculated 24 hours a day, calculated as 360 days per year, and the electricity cost is converted into 0.7 yuan/kW.h. The calculation is as follows (heat exchange efficiency is 65 % Calculation, the heat exchanger efficiency is calculated as 90%):

Recoverable heat per hour:

It can be seen from the unit conversion table that 1kWh=860kcal, and the heat available for a single air compressor is:

Counting the number of employees using the recovered heat to bathe

The amount of hot water that can produce 40℃ per hour is:

45 (temperature difference)

It can produce 1165 hot water every day; 24=27960kg=27 tons. If the bath is 100kg per person per day, 270 people can bathe.

The future of air compressor waste heat recovery is bright

With the continuous improvement of the domestic socio-economic level, the corresponding prices of various energy products continue to rise. Energy consumption is vital to the production and operation of industrial enterprises. The energy costs faced by enterprises are also increasing day by day, so corresponding to the necessity of improving facility energy conservation more and more important.

At the same time, with the increasing innovation of science and technology, energy-saving research in the field of waste heat recovery has been rapidly developed, and the waste heat recovery of air compressors has been substantially developed and utilized. Facts have proved that using the waste heat of the air compressor to provide heat not only does not affect the normal operation of the air compressor, but also is very beneficial to the operation of the air compressor system.

One time investment, endless benefits. In the era of environmental protection and energy saving, the benefits and advantages of air compressor waste heat recovery will become more and more obvious.