R410a refrigerant vacuum training

The first step of vacuuming

Steps for installing and connecting the internal and external machines...Connect the pipes connecting the internal and external machines, tighten...

Here is an explanation against PP...The thin pipe interface above is a two-way valve...The thick pipe interface is a three-way valve...

The second step of vacuuming

Connect a pressure gauge to the three-way valve repair port of the trachea (thick pipe) to connect to the vacuum pump. First turn on the pump and then open the pressure gauge valve. After the vacuum starts, set the pressure to minus 0.1 MPA, and then pump for 15-20 minutes. The negative pressure value is subject to...

Let’s take a look at the value of the pressure gauge before connecting it...

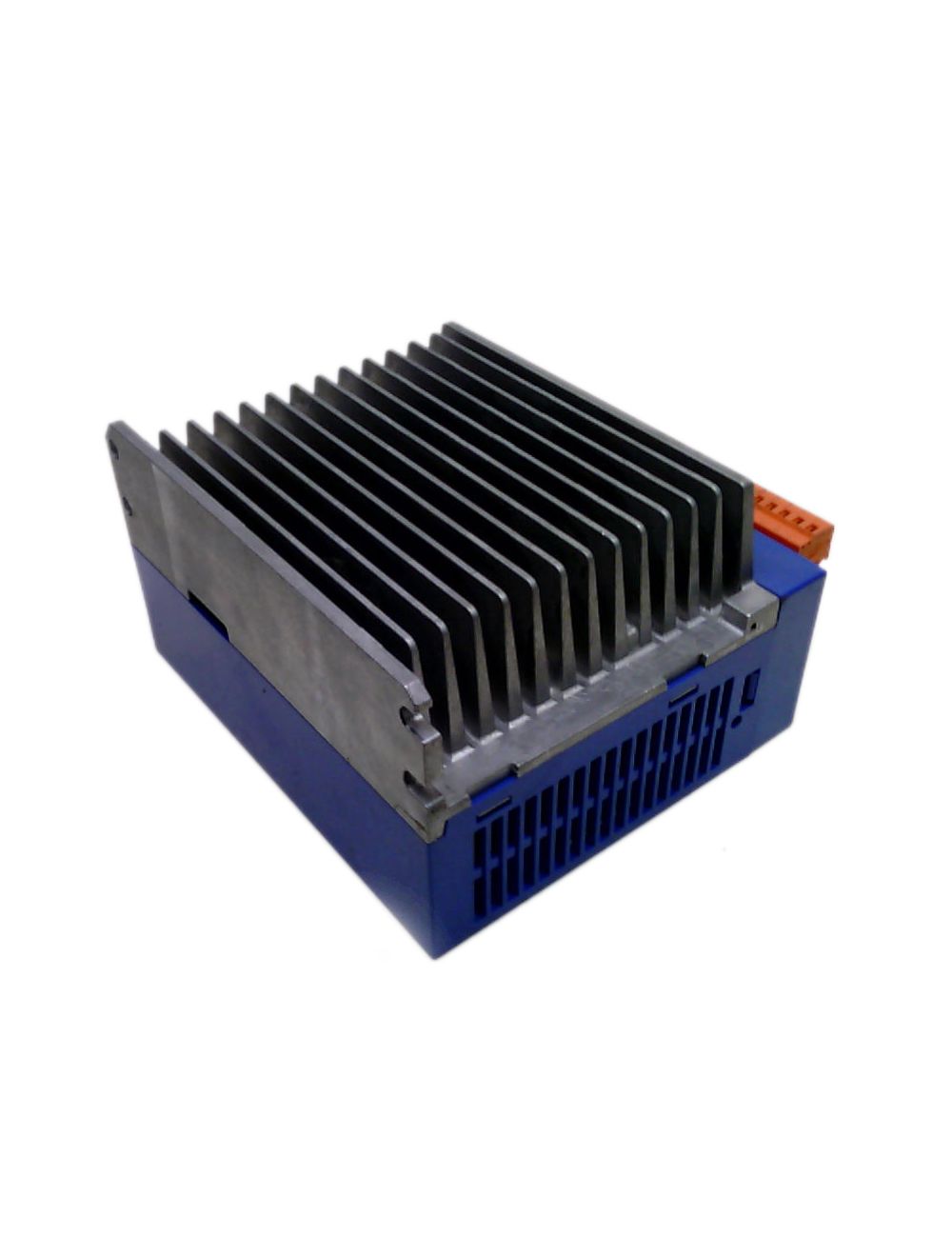

The double head watch looks like this...

Connect the pressure gauge to the vacuum pump with a blue tube...

The air pipe (thick pipe) of the external machine is connected to the pressure gauge with a red pipe to the three-way valve repair port...

Check whether the connections are tight...

purpose

A, remove the air in the connecting pipe and the indoor unit

B, the boiling point of water under vacuum is reduced. At present, in order to reduce costs, most manufacturers in my country and the connecting pipe are no longer protected by inert gas. The air containing water will enter oxidation and other impurities may adsorb water.

C, the pressure is only to ensure that the air is roughly discharged, and enough time is the guarantee for the complete removal of water

All connected...

It is recommended to turn on the pump first, then open the pressure gauge valve, and start the vacuum...

Now check the value of the pressure gauge...

Vacuuming officially begins...

The suggestion is to set the pressure to negative 0.1MPA, and then pump for 15-20 minutes, based on the negative pressure value of the pressure gauge...

The third step of vacuuming

Close the pressure gauge valve first, then turn off the vacuum pump...Look at the pressure gauge and observe whether the pressure rises...

Purpose:

A, to prevent the lubricating oil in the real pump from entering the air-conditioning system under negative pressure. Different types of lubricating oil can cause damage to the air-conditioning system, especially the R410A system. All adjustments should use a vacuum pump with a toe-back device to prevent air backflow

B, pressure-holding leak detection (it is a negative pressure leak detection method, just observe whether the pressure rises, I think positive pressure leak detection is more clear)

The fourth step of vacuuming

Use an inner hexagon wrench to open the liquid pipe valve (a thin tube two-way valve 1/4 circle), and close it after about 10 seconds. Use a leak detector or soapy water to detect the position of the connector...

Pick up the table, open all liquid pipe gas/pipe valves, open the debugging machine...

Note: The installer must use the inner hexagon before removing the vacuum pump pressure gauge connection! Many installers made mistakes in this step, which caused the air conditioner to be mixed with air again, and the vacuum effect was poor. If the action is slow, it will be a waste...