Refrigerant and its leak detection

Nowadays, electronic technology has penetrated into all areas of life and has helped us simplify our daily routines. The refrigeration industry is no exception. In terms of refrigerant leak detection, traditional and simple leak detection methods are still the mainstream. However, because most of these methods require a lot of manpower, and the results can only be obtained by visual observation, and the effects and accuracy are poor, new and electronic leak detection methods are gradually becoming necessary. This not only brings more accurate and reliable leak detection results, but also improves detection efficiency.

1. Overview of refrigerant

1. Refrigerant, compressor, evaporator, throttle and condenser are the five main components of refrigeration system.

2. The refrigerant circulates in the refrigeration system as a fluid to absorb and release energy.

3. When the refrigeration system is running, most of the refrigerant exists in the condenser and evaporator in liquid or gas saturated form.

4. There are three forms of refrigerant in the refrigeration system, liquid (supercooling), steam (superheating) and saturated (gas-liquid mixing).

Saturated refrigerant is a mixture of liquid and vapor in any ratio.

The superheated state means that the refrigerant temperature is higher than the saturated evaporation temperature and exists completely in the form of vapor.

The supercooled state means that the refrigerant temperature is lower than the saturated condensation temperature and exists completely in liquid form.

5. The refrigerant has a specific chemical composition, usually named "R-XXX", and distinguished by different colors.

6. The refrigerant absorbs heat when it changes from liquid to steam, and it releases heat when it changes from steam to liquid.

7. When the refrigeration system is running, most of the refrigerant exists in the condenser and evaporator in liquid or gas saturated form.

8. A single-component refrigerant has a corresponding "pressure-temperature" relationship. When the system pressure drops, the refrigerant evaporates and the temperature rises.

9. The ideal refrigerant needs to meet the following characteristics:

Can carry a lot of heat when the shape changes;

Safe, stable and detectable;

Excellent compression characteristics, environmental protection and economy.

10. Although most refrigerants may be non-toxic, they are heavier than air and will replace the surrounding oxygen, so excessive leakage may cause suffocation.

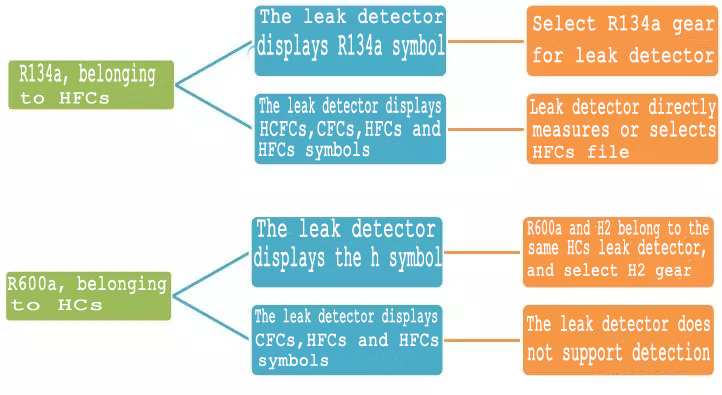

Most refrigerants can be divided into four categories according to their constituent elements:

HC: It is composed of H, F and C elements and represents refrigerant R600a.

CFC: Composed of Cl, F, and C elements, representing refrigerants R12, R113, and R114.

HFC: It is composed of H, F and C elements. Represents refrigerant R134a, R410A, R32.

HCFC: Composed of H, Cl, F, C elements, representing refrigerants R22, R123, R409a

2. Refrigerant leak detection:

Soapy water leak detection: pump high-pressure nitrogen into the system, and apply soapy water to the possible parts. The bubbling point is the leakage point, but it takes labor and time, and the detection effect is poor when the leakage is small.

Differential pressure leak detection: Determine whether there is a leak through the pressure change before and after the system pressure maintaining process. This method can only be qualitatively judged and cannot accurately find the leak point.

Fluorescence leak detection: the principle that the fluorescent leak detector emits bright yellow and green light under the irradiation of ultraviolet/blue leak detection lamp, but it takes a long time to mix the refrigerant and the fluorescent agent.

Electronic leak detector: The probe moves to the place where leakage may occur. If there is a leak, the leak detector will sound an alarm. This equipment is quick and easy to detect leaks.

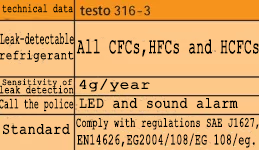

Q: Why is there HCFCs, CFCs, HFCs instead of HCFCs, CFCs, HFCs, but the refrigerant I need for the leak detector is not found in the manual of the electronic leak detector? As shown:

Answer: There are many types of refrigerants, and new refrigerants are constantly increasing, so use refrigerant classification symbols to indicate.

Question: Why is there only a small amount of refrigerant available for the electronic leak detector body? Are other refrigerants undetectable?

Answer: The principle of similar refrigerants is the same as that of the leak detector sensor. The body only displays the representative refrigerants of various types.

Choose the right leak detector:

3. Leak detection precautions & skills

1. Read the manufacturer's operating instructions carefully before operating the electronic leak detector.

2. When detecting compressor leakage, the compressor should be turned off.

3. The air-conditioning pipeline must ensure a certain amount of refrigerant charge. During leak detection, the gauge pressure of the pipeline shall not be lower than 3.4bar, and the temperature shall not be lower than 15℃.

4. If the measured object is dirty, avoid direct contact between the sensor and the measured object to prevent sensor contamination.

5. If the dirt is serious, wipe it with a dry, dust-free wipe or blow it with compressed air. Do not use cleaners or solvents to clean the test object, because the leak detector sensor may be sensitive to its components.

6. Before using the leak detector, look for any signs of lubricating oil leakage, damage, and corrosion of pipelines, hoses and components by visual inspection.

7. Use a leak detector to carefully check each suspicious area, including:

Accessories

Hose line connector

Throttle

Hooded access

Weld

Fixed connection point area

8. Always follow the flow direction of the refrigerant and perform leak detection along the continuous path of the refrigeration system. Even if a leak is found, the remaining parts should be measured.

9. When inspecting each area, move the leak detector probe at a speed of 2.5 ~ 5.0 cm/s and no more than 0.5 cm away from the detection surface for detection.

10. When an obvious leak is detected, it needs to be repeatedly blown and checked by compressed air. When the leak is large, this method helps to accurately locate the leak point.

11.When testing the evaporator core, turn on the fan, adjust to high wind blowing for

12.15 seconds, then turn off the fan and wait for 10 minutes. Then insert the leak detector probe into the wind resistance body or the condensate drain hole, or the heating/ventilation pipe closest to the evaporator.

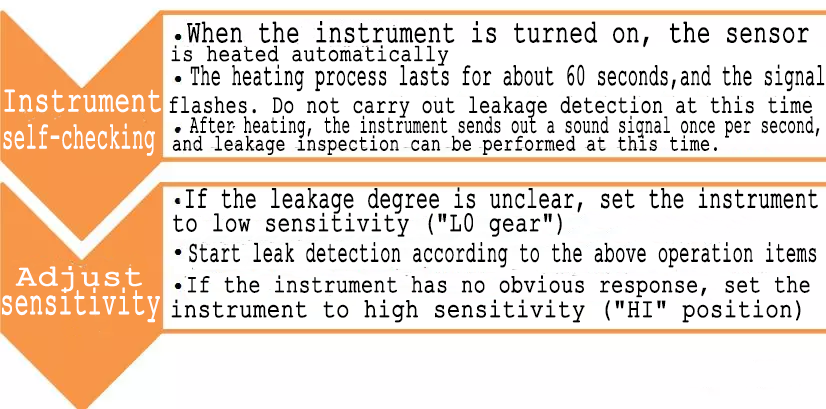

Fourth, the general operating process of the electronic leak detector

Take the testo 316-3 operation process of okmarts.com as an example: