The 210,000-kilometer Mercedes-Benz repaired the air conditioner, and the compressor and condenser were replaced. Owner: Looks good!

A few days ago, a Mercedes-Benz E200L came to the factory for inspection. The owner described only one problem, that is: the air conditioning outlet does not blow cool breeze. On such a hot day, if there is no cool breeze from the air outlet, the temperature inside the car will be very high, making it impossible to drive comfortably.

After inspection, the master found that the reason for not blowing the cool breeze was that the compressor did not work. The compressor is equivalent to the heart of the air conditioning system. If it does not work, the air conditioner will definitely not work. The reason why the compressor will not work is that the intermediate shaft cannot rotate and the internal piston is defective. As shown in the figure below, the mileage displayed by the meter is 210,000 kilometers.

After further inspection, the repair plan given by the master is: replace the compressor and condenser. The owner agreed to this repair. However, when the car owner saw the removed old parts, he was very confused, because the compressor and condenser that were replaced did not seem to be a problem, so why should I replace them?

Let's look at the picture below. This is an old condenser that has been replaced. Although it looks dirty, there is no leakage of refrigerant on its front and pipe connections.

Let's look at the picture below. This is an old compressor. From the outside, there is no leakage of refrigerant, but it needs to be replaced.

Seeing the car owner’s doubts, the master took the compressor and said to the car owner that the wheel shown by the orange arrow is connected to the belt and it can always rotate. When the air conditioner is needed, the middle shaft shown by the green arrow will rotate and the compressor will work. However, its intermediate shaft was completely unable to rotate, holding the compressor swaying, and there was a clattering sound inside, so it had to be replaced.

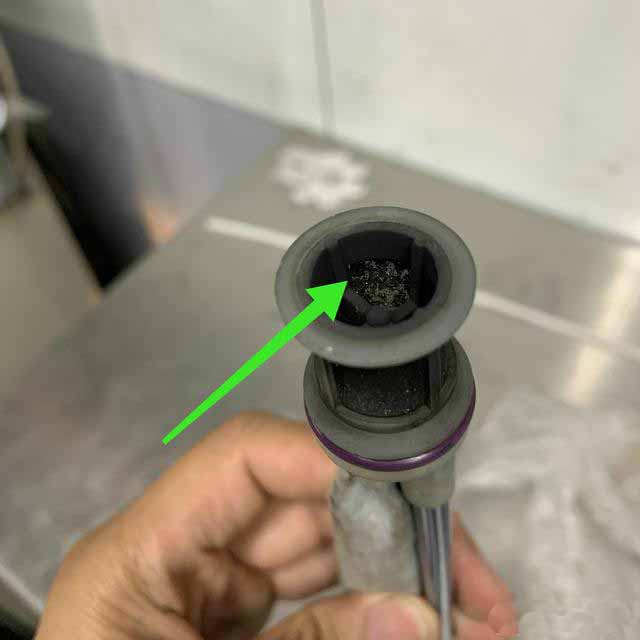

After explaining the compressor, the master took out something from the edge of the condenser and told the owner that this is a filter bag installed in the condenser, which can filter the impurities and moisture in the refrigerant. See the green arrow. There are many impurities, and there are many impurities at the end shown by the orange arrow.

We continue to look at the green arrow. Most of the impurities in the filter are shiny metal debris, and most of the impurities at the end of the drying bag are also metal debris, which is very abnormal. So, where do these metal scraps come from?

According to the master, the metal debris at the end of the filter and the drying bag comes from the compressor. The piston inside the compressor produces metal debris due to severe wear. These very small metal debris will enter the condenser, and the holes in the condenser It is extremely small, and it is very difficult to clean up after being blocked by these metal chips, so it needs to be replaced.

If the condenser is not replaced, but the compressor is replaced, the metal debris that cannot be cleaned out of the condenser will enter the new compressor and accelerate the damage of the new compressor. The master has suffered such a loss. As shown in the figure below, the new condenser has been installed by the master.

Now, the owner of the car understands that the compressor and condenser must be replaced. The evaporator is far away from the compressor, and after the refrigerant comes out of the compressor, it passes through the condenser first. The metal scraps are basically left in the condenser, so the evaporator does not need to be replaced.

After the new condenser and compressor were installed, the master performed pressure leak testing and vacuuming operations, and then added refrigerant. The result: the cool breeze is really cool! Hope this simple repair case can be helpful to riders!