The working principle of air compressor

working principle

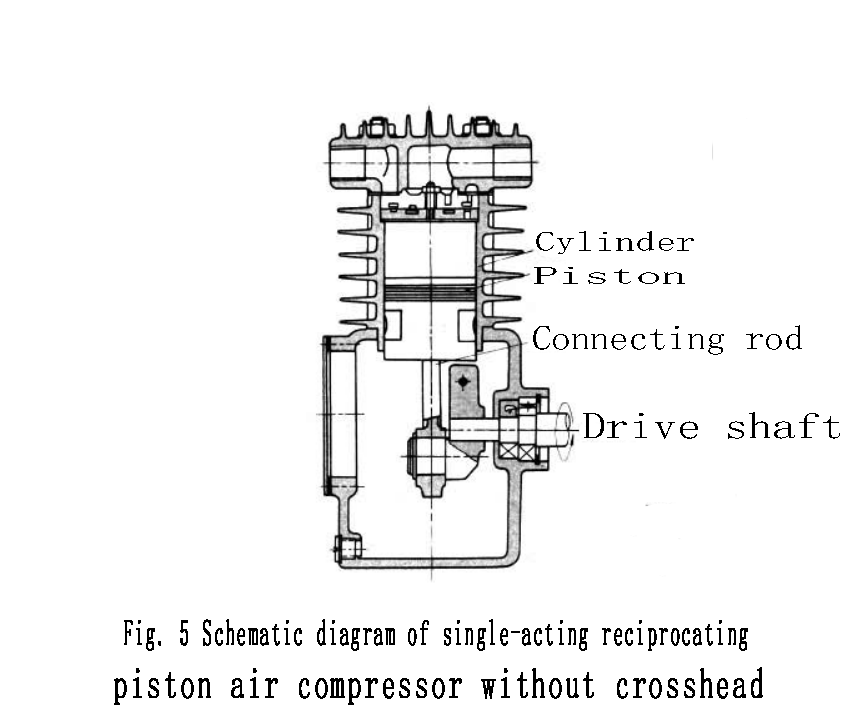

(1) Piston air compressor

This is the most commonly used form of air compressor. The working principle is that when the piston moves to the right, the pressure in the left cavity of the piston in the cylinder is lower than the atmospheric pressure, the suction valve opens, and outside air enters the cylinder. This process is called the "inhalation process". When the piston moves to the left, the gas in the cylinder is compressed. This process is called the "compression process". When the pressure in the cylinder is higher than the pressure in the output pipe, the exhaust valve is opened and the compressed air is delivered to the pipe. This process is called "exhaust process". The reciprocating motion of the piston is driven by the motor to drive the crank to rotate, and the slider is driven to move in the slideway through the connecting rod, and the piston rod drives the piston to make a linear reciprocating motion in the cylinder.

Single-stage piston air compressor is often used in systems that require a pressure range of 0.3~0.7MPa. The pressure of a single-stage air compressor exceeds 0.6MPa, the heat generated is too large, and the working efficiency of the air compressor is too low, so a two-stage piston air compressor is often used, as shown in Figure 8-3. If the final force is 1.0 MPa, the first stage is usually compressed to 0.3 MPa. The intercooler is set to reduce the inlet air temperature of the second stage piston to improve the working efficiency of the air compressor.

(2) sliding vane air compressor

The working principle of the sliding vane air compressor. The rotor is eccentrically installed in the stator, and a set of sliding plates are inserted in the radial slots of the rotor. When the rotor rotates, the sliding vanes cling to the inner wall of the stator mainly by centrifugal action. During the rotation of the rotor, the left half (input port) sucks in air. In the right half, the sliding vane is gradually pressed into the rotor groove by the inner surface of the stator, the volume enclosed by the sliding vane, the rotor and the inner wall of the stator gradually decreases, the inhaled air is gradually compressed, and finally the compressed air is discharged from the output port . Since oil is sprayed into the air flow near the input port to lubricate, cool and seal the sliding vane and the stator, the compressed air that is output and higher contains a large amount of oil, so an oil mist separator and cooler must be installed at the output port. In order to separate the oil from the compressed air, recycle it after cooling.

(3)Screw type air compressor

The working principle of screw air compressor is shown in Figure 8-5. The two interlocking spiral rotors rotate in opposite directions, and the volume of the free space among them gradually decreases along the axial direction, so that the air between the two rotors is gradually compressed. If the rotor and the casing are not in contact with each other, there is no need for lubrication, so that the air compressor can output oil-free compressed air. It can continuously output compressed air with large flow without pulsation, and the outlet air temperature is about 60℃.