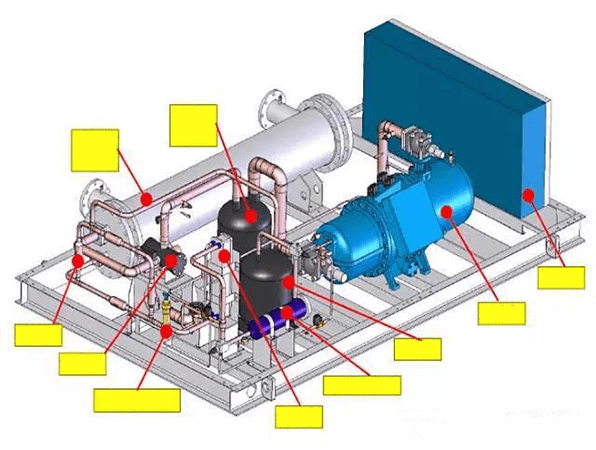

Figure 1: Screw chiller unit.

Water chillers are machines that are used to cool water and maintain a specific temperature for various industrial processes. They are an essential component in industries such as pharmaceuticals, food and beverage, plastics, and many more. Water chillers come in various types and models, each with unique features and benefits.

In this article, we'll take a closer look at the different types of water chillers based on their condenser and compressor type. Before introducing the types of water chillers, it is necessary to know the basics about water chillers. The water chiller we mention in this article refers to a vapor-compression type chiller.

1. Water Chillers Basics

Water chillers are machines used to cool water and maintain a specific temperature for various industrial processes. They work on the principle of the vapor compression cycle and have four essential components: the compressor, condenser, expansion valve, and evaporator.

The compressor compresses the refrigerant, increasing its temperature and pressure. The refrigerant then flows to the condenser, where it releases the heat it has absorbed. The expansion valve reduces the pressure and temperature of the refrigerant, allowing it to absorb heat. The refrigerant then flows to the evaporator, where it absorbs heat from the water.

Water chillers are used in various applications, including plastics, food and beverage, pharmaceuticals, data centers, and hospitals.

Figure 2: Water chiller working principle diagram.

2. Chiller Condenser Types

According to the different heat dissipation methods of the condenser, chillers can be divided into air cooled chillers and water cooled chillers.

2.1 Air-Cooled Chillers

Air-cooled chillers are the most common type of water chillers used in the industry. They use ambient air to cool the refrigerant. The refrigerant absorbs the heat from the water and releases it into the air through a heat exchanger and a fan. Air-cooled chillers are typically used in environments where water is scarce or expensive.

Air-cooled chillers have several advantages over water cooled chillers. They are easy to install and require minimal maintenance. However, they are less efficient than water-cooled chillers and can be noisy.

Figure 3: Working principle diagram of the air-cooled chiller.

1. Compressor 2. High pressure controller 3. Condenser 4. Dry filter 5. Expansion valve 6. Antifreeze switch 7. Evaporator 8. Low pressure controller, 9. Water pump 10. Water tank 11. Float switch 12. Globe valve 13. Motor 14. Fan

2.2 Water-Cooled Chillers

Water-cooled chillers use water to cool the refrigerant. The refrigerant absorbs the heat from the water and releases it into the circulating water through the condenser, which is also cooled by a cooling tower. Water-cooled chillers are typically used in environments where water is readily available.

Water-cooled chillers have several advantages over air-cooled chillers. They are more efficient and can handle larger cooling loads. They are also quieter than air-cooled chillers. However, they require more maintenance.

Figure 4: Water cooled chiller working principle diagram.

1. Compressor 2. Condenser 3.High pressure switch 4. Dry filter 5.Expansion valve 6. Evaporator 7. Low pressure switch 8. Cold water pump 9. Water tank 10. Float switch 11.Ball valve 12. Cooling water pump 13. Cooling tower

3. Chiller Compressor Types

According to the different compressors used, chillers can be divided into reciprocating chillers, scroll chillers, screw chillers, centrifugal chillers. Besides, there is magnetic bearing centrifugal chiller as the magnetic magnetic levitation technique is used in the centrifugal compressor.

3.1 Reciprocating Chillers

Reciprocating chillers use a reciprocating compressor to compress the refrigerant. They are typically used in small to medium-sized applications, such as laboratories or small production facilities. Reciprocating chillers are known for their reliability and durability. They are also energy efficient and require minimal maintenance.

3.2 Scroll Chillers

Scroll chillers use a scroll compressor to compress the refrigerant. They are typically used in small to medium-sized commercial or industrial applications. Scroll chillers are known for their efficiency, low noise levels, and low maintenance requirements. They are also easy to install and operate.

3.3 Screw Chillers

Screw chillers use a screw compressor to compress the refrigerant. They are typically used in large commercial or industrial applications, where a large cooling load is required. Screw chillers are known for their high efficiency and reliability. They are also easy to maintain and have a long lifespan.

Figure 5: Structural diagram of screw chiller.

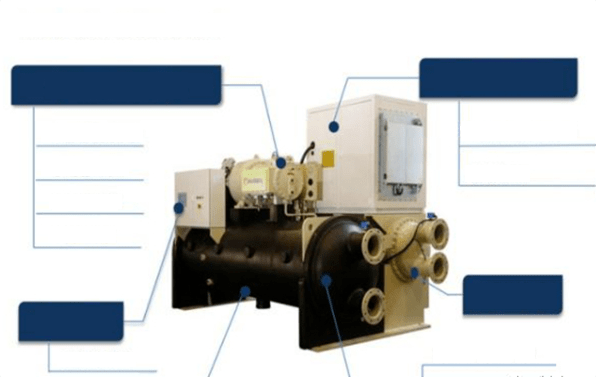

3.4 Centrifugal Chillers

Centrifugal chillers use a centrifugal compressor to compress the refrigerant. They are typically used in large commercial or industrial applications where a large cooling load is required. The refrigerant is compressed by a high-speed impeller, which then passes through a diffuser to slow the flow down. The refrigerant then passes through a heat exchanger, where it is cooled before being pumped back into the chiller.

Centrifugal chillers have several advantages over other types of chillers. They are highly efficient and can handle large cooling loads. They are also very reliable and require minimal maintenance. However, they are more expensive than other types of chillers and require a large footprint.

Figure 6: Centrifugal chiller diagram.

3.5 Magnetic Bearing Centrifugal Chiller

The magnetic bearing centrifugal chiller (magnetic levitation chiller) refers to the magnetic levitation technology used in the centrifugal chiller compressor, which uses a magnetic field to suspend the rotor. When the rotor is rotating, there is no mechanical contact with the impeller, no mechanical wear, and no mechanical bearings and corresponding lubrication systems are required. Reduced mechanical loss making refrigeration operation more efficient and energy-saving.

Figure 7: Magnetic bearing centrifugal chiller unit.

From the structural diagram, we can see that compared with the ordinary variable speed centrifugal chiller, the key difference of the magnetic bearing variable speed centrifugal chiller lies in the magnetic levitation centrifugal compressor. The magnetic levitation system is composed of four parts: rotor, sensor, controller and actuator. The actuator includes two parts: electromagnet and power amplifier.

Magnetic bearing variable speed centrifugal chillers have the following advantages.

1. Energy saving

2. Low daily maintenance cost

3. Low running noise and vibration

4. No friction loss

5. Low starting current

6. High system sustainability

4. Conclusion

In conclusion, water chillers are crucial machines in various industries that require specific temperatures for their processes. The type of chiller used depends on the application, cooling load, and availability of water. Each type of water chiller has its unique features and benefits, and choosing the right type of chiller for your application can help you save energy, reduce costs, and increase productivity.

Related Info

Geothermal vs Air Source Heat Pump: Which One is Right for You?Geothermal, Air Source, and Water Source Heat Pumps: Which is the Best?

Water-Cooled Chiller vs Air-Cooled Chiller: Which One is Better?

Chilled Water System: Basics, Working Principle Diagram, Types and More

Ground Source Heat Pump: a Complete Guide