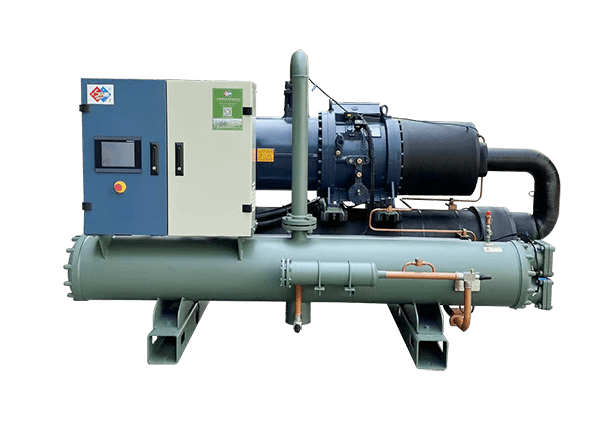

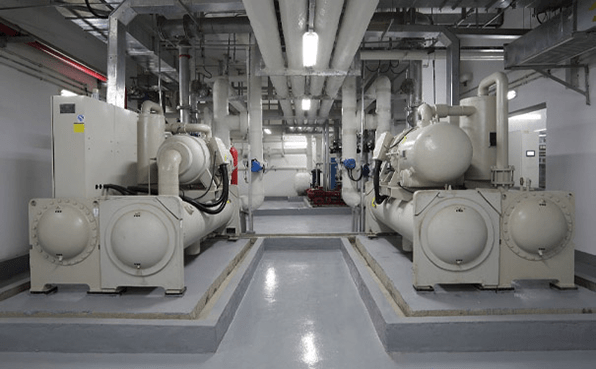

Figure 1: Water-cooled chiller unit.

When it comes to cooling systems for large commercial buildings or industrial facilities, two of the most common options are water-cooled chillers and air-cooled chillers. Both types of chillers are designed to remove heat from a building or industrial process, but they operate in different ways and have their own unique advantages and disadvantages.

In this article, we will explore what a chiller is, the differences between water-cooled chillers and air-cooled chillers, and discuss the factors that should be considered when choosing between the two.

1. What is a Chiller?

A chiller (vapor compression chiller) is a machine that removes heat from a liquid, typically water, and transfers it to the surrounding air or water. Chillers are commonly used in air conditioning systems, industrial processes, and other applications where cooling is required.

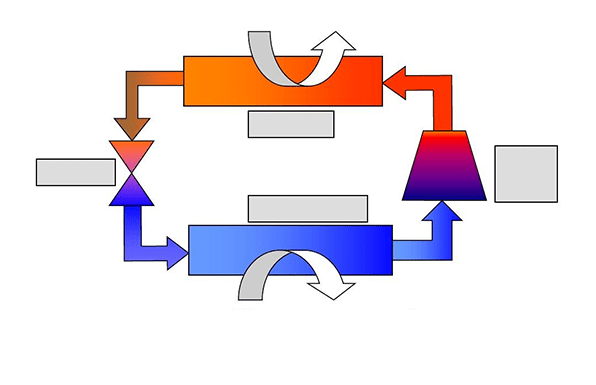

The basic operation of a chiller involves circulating a refrigerant, which absorbs heat from the liquid being cooled at the evaporator and then releases it to the environment. The refrigerant is typically compressed by the compressor to increase its temperature, and then enters the condenser to release heat. After passing through the expansion valve, the cooled refrigerant is then circulated back to the evaporator where it absorbs heat, and the cycle continues.

Water cooled and air cooled chillers are two main types of chillers. The biggest difference between them is how their condensers are cooled. A water cooled chiller is cooled by water while a air cooled chiller by air, as their names imply.

Figure 2: Chiller refrigeration schematic diagram.

2. What are Water-Cooled Chillers?

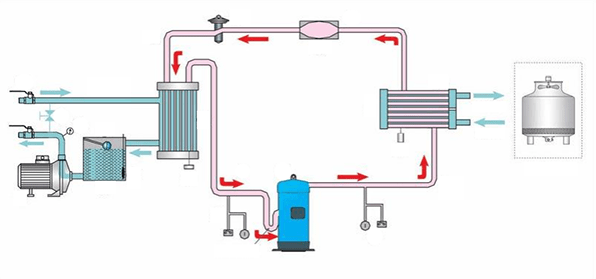

Water-Cooled Chillers typically consist of a chiller unit (including a compressor, evaporator, condenser, and expansion valve), cooling tower, pumps and piping, etc.

They circulate water through a closed loop system to cool the condenser. After flowing through the condenser, the water is circulated through the piping system to the cooling tower where the water is further cooled and the heat is released into the atmosphere. The cooled water is then returned to the chiller unit to continue the cycle.

Figure 3: Working principle diagram of water-cooled chiller.

①Compressor ②Condenser ③Filter drier ④Expansion valve ⑤Evaporator ⑥Globe valve ⑦Antifreeze valve ⑧Float valve ⑨Temperature sensor ⑩ Water tank ⑪Pump pressure gauge ⑫Pump ⑬Bypass valve ⑭Low pressure control ⑮High pressure control ⑯Pressure relief valve

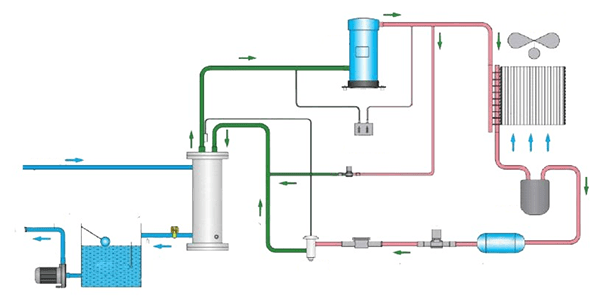

3. What are Air-Cooled Chillers?

Air-cooled chillers are cooling systems that use air to cool the condenser. Air-cooled chillers typically consist of a compressor, an evaporator, a fan-cooled condenser, and an expansion valve. The compressor compresses the refrigerant and sends it to the condenser, where it releases heat to the surrounding air. The refrigerant then flows through the expansion valve, which lowers its pressure and temperature, allowing it to absorb heat from the building or process in the evaporator.

Figure 4: Working principle diagram of an air-cooled chiller.

4. Water-Cooled Chiller vs Air-Cooled Chiller on Different Aspects

1. Heat Dissipation Method: Air-cooled chillers use a fan to suck in air to dissipate heat. The water-cooled chiller uses water circulation to take out the heat.

2. Energy efficiency: Water-cooled chillers are generally more energy-efficient than air-cooled chillers, as water is a better heat transfer medium than air. However, the energy efficiency of both types of chillers depends on various factors such as the design, operating conditions, and load.

3. Cooling capacity: Water-cooled chillers provide greater cooling capacity than air-cooled chillers.

4. Water conservation: Water-cooled chillers consume a significant amount of water, and the water used in the cooling tower requires treatment to prevent scaling and corrosion. Air-cooled chillers do not consume water, making them more water-efficient.

5. Longevity: Water-cooled chillers generally have a longer lifespan than air-cooled chillers, as they are more durable and have fewer components that are exposed to outdoor conditions. However, the longevity of both types of chillers depends on various factors such as maintenance, operating conditions, and load.

6. Application Areas: Water-cooled chillers are commonly used in large commercial and industrial applications where high cooling capacity is required. Air-cooled chillers are suitable for small to medium-sized commercial and industrial applications where lower cooling capacity is required and water is not readily available or practical to use.

Figure 5: Water cooled chiller unit.

7. Cost: Air-cooled chillers are generally less expensive to install and maintain than water-cooled chillers, as they do not require a cooling tower. However, the cost of both types of chillers depends on various factors such as capacity, brand, and features.

8. Maintenance: Water-cooled chillers require more maintenance than air-cooled chillers, as they have more components and require a cooling tower and water treatment system. Air-cooled chillers are generally easier to maintain, as they have fewer components and do not require water treatment.

9. Installation: Water-cooled chillers are typically more complex to install than air-cooled chillers, as they require a cooling tower and water supply system. Air-cooled chillers are generally easier to install, as they do not require additional equipment such as a cooling tower.

5. FAQs

5.1 Why Water-Cooled Chiller is More Efficient than Air-Cooled Chiller?

Water-cooled chillers are more efficient than air-cooled chillers because water is a better heat transfer medium than air. Water has a higher heat capacity and thermal conductivity than air, which means it can absorb and transfer more heat than air.

Additionally, water-cooled chillers have a higher heat transfer coefficient than air-cooled chillers, which means they can transfer heat more efficiently. This allows water-cooled chillers to operate at higher efficiencies and provide greater cooling capacity than air-cooled chillers.

Figure 6: Air cooled chiller unit.

5.2 Which is Better Air-Cooled Chiller or Water Cool Chiller?

It depends on the specific cooling needs of the building or process, as well as factors such as location, weather, energy efficiency, maintenance, water conservation, and cost.

Water-cooled chillers are generally more efficient and better suited for high-capacity cooling applications, while air-cooled chillers are suitable for smaller to medium-sized applications where lower cooling capacity is required and water is not readily available or practical to use.

Air-cooled chillers are generally less expensive to install and maintain than water-cooled chillers, but may have higher energy costs due to their lower energy efficiency.

Ultimately, the selection of an air-cooled or water-cooled chiller should be based on careful analysis of the specific application and its requirements.

5.3 What is the Advantage of Water-Cooled Chiller?

The main advantage of water-cooled chillers is their higher energy efficiency compared to air-cooled chillers. Water is a better heat transfer medium than air, which means water-cooled chillers can provide greater cooling capacity using less energy.

Additionally, water-cooled chillers are typically quieter and have a smaller footprint than air-cooled chillers, making them suitable for a wide range of applications.

Figure 7: Water cooled chiller application.

5.4 Why is it Better to Use a Chilled Water System over an Air-Cooled System?

When having the following requirements, it is better to use a chilled water system over an air-cooled system:

High cooling loads: Chilled water systems are more efficient than air-cooled systems in providing high cooling loads, making them suitable for large commercial and industrial applications such as data centers, hospitals, and manufacturing plants.

Noise reduction: Chilled water systems are typically quieter than air-cooled systems, which can be important in noise-sensitive applications such as hospitals and schools.

Energy efficiency: Chilled water systems are generally more energy-efficient than air-cooled systems, which can result in lower operating costs over the life of the system.

Related Info

Geothermal vs Air Source Heat Pump: Which One is Right for You?Geothermal, Air Source, and Water Source Heat Pumps: Which is the Best?

Heat Pump Water Heaters Pros and Cons: Is It the Right Choice for Your Home?

Heat Pump Water Heaters: Complete Guide, Working Principle, Types, Pros and Cons and More

Ground Source Heat Pump: a Complete Guide