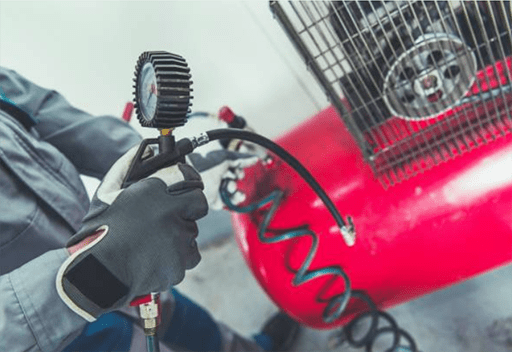

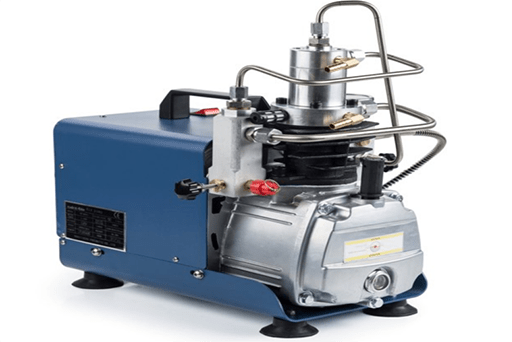

Figure 1: Air Compressor.

An air compressor is a pneumatic device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure.

1. Why We Need It

Air compressors are versatile and vital components of any factory or workshop. They’ve become smaller and less bulky in recent years, making them more usable in various work situations. These are highly useful portable machines that power single air tools.

The main advantage of air compressors is that they’re much more powerful than regular tools, and they don’t require their own bulky motors. Since the only real maintenance that’s required of them is a little bit of oiling, a variety of tools can be powered by a single engine that utilizes air pressure for maximum potential.

2. How Air Compressors Work

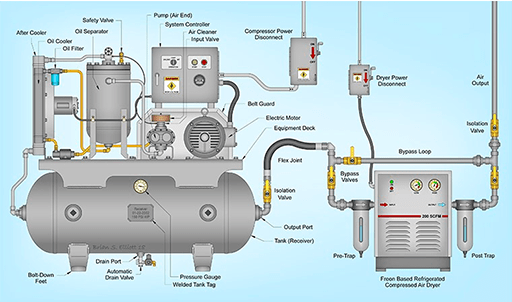

Figure 2: Structure of the air compressor.

Single-stage, piston-type air compressors are the most common models for home use and work well for many applications around the home or workshop. An electric motor or gasoline engine drives a piston, which compresses air and forces it into a storage tank. As the piston forces more air in, the air pressure rises. Once the pressure reaches a specified level, the compressor stops running. As you use the stored air to power a tool, the compressor restarts to build the air pressure back up.

Two-stage compressors have two pistons. The first compresses the air and pushes it through a check valve to the second piston, which compresses it further and delivers it to the tank. These compressors are usually heavy-duty, commercial models that can deliver a greater volume of air at higher pounds per square inch (PSI) levels. They're good choices for continuous use in shops or to power multiple tools at once.

3. Classification

Compressors can be classified according to the pressure delivered:

Low-pressure air compressors (LPACs), which have a discharge pressure of 150 pounds per square inch (10 bar) or less.

Figure 3: Low-pressure air compressor (LPAC).

Medium-pressure compressors which have a discharge pressure of 151 to 1,000 pounds per square inch (10.4 to 68.9 bar).

Figure 4: Medium-pressure compressor.

High-pressure air compressors (HPACs), which have a discharge pressure above 1,000 pounds per square inch (69 bar).

Figure 5: High-pressure air compressor (HPAC).

4. Application

Air compressors have many uses, including: supplying high-pressure clean air to fill gas cylinders, supplying moderate-pressure clean air to a submerged surface supplied diver, supplying moderate-pressure clean air for driving some office and school building pneumatic HVAC control system valves, supplying a large amount of moderate-pressure air to power pneumatic tools, such as jackhammers, filling high pressure air tanks (HPA, air tank), for filling tires, and to produce large volumes of moderate-pressure air for large-scale industrial processes (such as oxidation for petroleum coking or cement plant bag house purge systems)

Air compressors are also widely used in oil and gas, mining and drilling applications as the flushing medium, aerating muds in underbalanced drilling and in air pigging of pipelines.

Related Info

How to Choose an Air CompressorHow to Use an Air Compressor

How to Set Air Compressor Pressure

What is A Mechanical Sealing