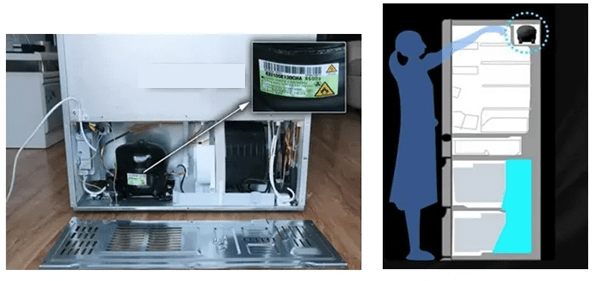

Figure 1: LG refrigerator compressor.

We all know that in addition to electricity, refrigerators rely on refrigerator compressor to maintain normal operation. The compressor is like the heart of the refrigerator. It is the power component of the refrigeration cycle system of the refrigerator. Its quality directly affects the refrigeration capacity of the refrigerator. So when buying a refrigerator, let's pay more attention to the refrigerator compressor.

1. Refrigerator Compressor Location

Generally, refrigerator compressors are installed at the bottom of refrigerators, and sometimes on the top of the refrigerator, as shown in the figure below:

Figure 2: The installation position of the compressor in the refrigerator.

2. How Does a Refrigerator Work

In terms of the components of the refrigerator, the refrigeration system consists of a compressor, a condenser, a dry filter, a capillary tube, and an evaporator. The refrigerator refrigeration system includes four major working processes.

Figure 3: Working process diagram of refrigerator.

2.1 Compression Process

After the refrigerator is powered on, if the refrigerator does not reach the set temperature, the contact of the thermostat is connected, and the compressor starts to work. The low-temperature and low-pressure refrigerant is sucked into the compressor, compressed into high-temperature and high-pressure hot gas in the cylinder of the compressor, and then discharged into the condenser.

2.2 Condensation Process

The high-temperature and high-pressure refrigerant gas dissipates heat through the condenser, the temperature gradually drops, and is slowly cooled to normal temperature, high-pressure saturated steam, and further cooled to saturated liquid. When its temperature does not drop anymore, the temperature at this time is called the condensation temperature. There is little change in pressure of the refrigerant throughout the condensation process.

2.3 Throttling Process

Then the refrigerant saturated liquid flows into the capillary tubes after the filter drier filters out moisture and impurities. Through the throttling function of the capillary tubes, the refrigerant becomes normal temperature and low pressure wet steam.

2.4 Evaporation Process

The refrigerant begins to absorb heat in the evaporator to vaporize, and the temperature of the evaporator and the surrounding area drops. The refrigerant becomes a low-temperature, low-pressure gas at this time, and the refrigerant coming out of the evaporator returns to the compressor again.

Through the above 4 processes, the refrigerant transfers the heat in the refrigerator to the air outside the refrigerator to achieve the purpose of cooling. When the temperature in the refrigerator reaches the set temperature, the contact of the thermostat is electrically disconnected and the compressor stops working.

|

Device |

Refrigerant state |

Refrigerant Pressure |

Refrigerant Temperature |

|

Compressor |

Gas→Gas |

Low→High |

Low→High |

|

Condenser |

Gas→Liquid |

High pressure |

High→Medium |

|

Filter drier |

Liquid |

High pressure |

|

|

Capillary tube |

Liquid→liquid |

High →Low |

|

|

Evaporator |

Liquid →Gas |

Low pressure |

Medium→Low |

Table 1: Different states, pressure and temperature of the refrigerant in each device (pipeline).

3. Types of Compressors Used in Domestic Refrigerators

3.1 Reciprocating / Piston Compressor

When the crankshaft of the piston compressor rotates, the piston will reciprocate through the transmission of the connecting rod, and the working volume composed of the inner wall of the cylinder, the cylinder head and the top surface of the piston will change periodically.

When the piston of the piston compressor starts to move from the cylinder head, the working volume in the cylinder gradually increases. At this time, the gas goes along the intake pipe, pushes the intake valve and enters the cylinder until the working volume becomes larger to a certain extent, and then the intake valve will be closed.

When the piston of the piston compressor moves in reverse, the working volume in the cylinder decreases and the gas pressure increases. When the pressure in the cylinder reaches a certain extent and is slightly higher than the exhaust pressure, the exhaust valve opens and the gas is discharged from the cylinder until the piston moves to the limit position. Then the exhaust valve is closed.

In short, the crankshaft of the piston compressor rotates a round, the piston reciprocates once, and the process of gas intake, compression, and exhaust is successively realized in the cylinder, that is, a working cycle is completed.

Figure 4: The structure diagram of a hermetic piston refrigeration compressor.

3.2 Screw Compressor

The screw compressor uses the male and female rotors with spiral tooth grooves placed in the cylinder to mesh with each other and rotate, so that a series of inter-tooth volumes in the shape of a "V" formed by the teeth, tooth grooves and the inner wall of the casing periodically change. Then it completes the working process of gas suction, compression and discharge.

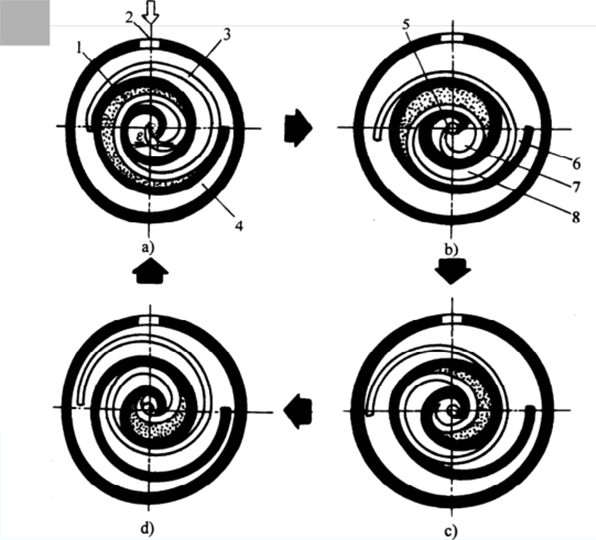

3.3 Scroll Compressor

The working process of the scroll compressor only has three processes of gas intake, compression, and exhaust, and they are performed simultaneously within one revolution of the main shaft.

The outer space communicates with the suction port and is always in the suction process. The inner space communicates with the exhaust port and is always in the exhaust process, while the crescent-shaped closed space between the above two spaces is always in the process of compression. Furthermore, both the suction and exhaust processes are continuous.

Figure 5: Schematic diagram of the working principle of a scroll compressor.

a) 0° position, b) 90° position, c) 180° position, d) 270° position

1-Compression chamber 2-Intake port 3-Orbiting scroll 4-Fixed scroll 4-Exhaust port 6-Suction chamber 7-Exhaust chamber 8-Compression chamber

3.4 Linear Compressor

A linear compressor is a machine driven by the principle of electromagnetic and mechanical vibration to increase the gas pressure and provide power for refrigeration, also known as electromagnetic compressor, oscillating compressor or free piston compressor.

Figure 6: Structural diagram of linear compressor produced by SUNPOWER company.

1-Spring 2-Permanent magnet 3-Cylinder block 4-Compression chamber 5-Muffler 6-Valve group 7-Exhaust pipe 8-Piston 9-Outer magnetic pole 10-Coil 11-Inner magnetic pole

The linear compressor uses a new reluctance linear motor to drive the compression rod to directly actuate the piston, so that the compressor has simple structure, easy control, high efficiency and energy saving. It can be applied to small refrigeration equipment such as refrigerators and air conditioners.

For small refrigeration equipment, the performance of the linear compressor will be superior to that of the commonly used reciprocating piston compressor. The linear compressor wears less, and has higher efficiency and economy, flexible control system, and better frequency conversion effect.

Therefore, the linear compressor is an ideal new model, which is expected to replace the existing reciprocating piston compressor.

3.5 Inverter Compressor

Inverter compressor refers to a compressor that can continuously change the output energy by continuously adjusting the speed within a certain range through a control method or means relative to the compressor with a constant speed.

The inverter compressor can be divided into two parts, one part is the variable frequency drive, which is what we often call the frequency converter; the other part is the compressor.

The principle of the variable frequency drive is to convert the alternating current in the grid into a square wave pulse output. By adjusting the frequency of the square wave pulse (that is, adjusting the duty cycle), the speed of the motor driving the compressor can be controlled. The higher the frequency, the higher the speed.

Another advantage of the frequency conversion controller is that the starting current of the drive motor is small, which will not cause a large impact on the power grid.

Figure 7: Invert refrigerator compressor.

3.6 General Inverter Compressor VS LG Linear Inverter Compressor

Refrigerator compressors can be roughly divided into two categories: traditional Panasonic, Embraco's crankshaft connecting rod reciprocating technology and LG's linear inverter technology.

The general inverter compressor uses a motor to drive the crank to adjust the distance and speed of the piston moving through the rotation speed, while the LG linear inverter compressor directly drives the piston through the compression rod, and control the speed of compressing air by adjusting the moving forward and back range of the piston to achieve operation.

Compared with Panasonic and Hitachi compressors, this structure is not a major breakthrough in overall performance, but it is at least an improvement. The compression rod directly drives the piston to simplify the internal structure, and reduce the noise of reciprocating parts, and the response speed of the compressor will be faster.

Figure 8: LG linear inverter refrigerator compressor.

At present, almost all of LG's refrigerators and air conditioners are equipped with LG linear inverter compressors. As the first company to industrialize linear compressors, it is at an industry-leading level in terms of noise control and compressor life. If you value the quality and low noise of a refrigerator, you can think about this brand.

4. Conclusion

At present, most of the mainstream compressors used in the refrigerator industry are: Panasonic, Embraco, Jiaxipera, Huayi, etc. When purchasing a refrigerator, you can check the compressor brand used from the product information details, or ask the customer service personnel directly.

Related Info

How to Tell if the Home AC Compressor is BadDifferent Types of Refrigeration Compressors and Their Applications, Brands

Top 10 Industrial Compressor Manufacturers in the World

AC Compressor Failure and Case Analysis

10 Causes of AC Compressor Failure & 4 Ways to Prevent It