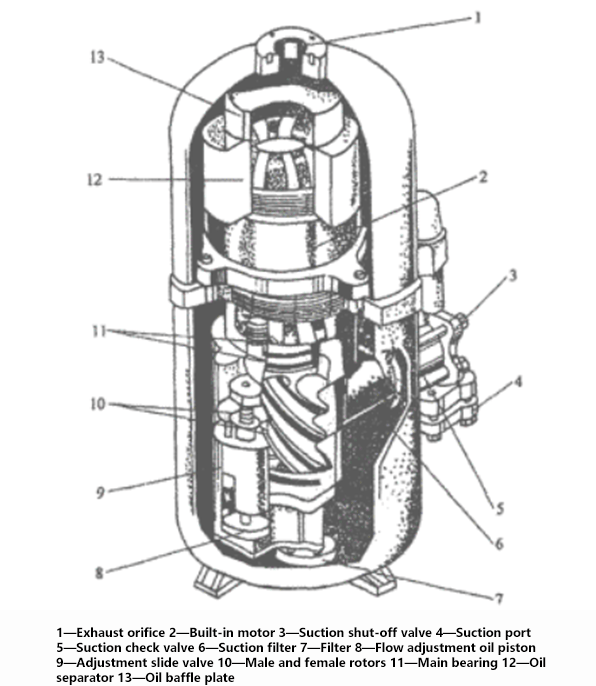

Figure 1: German Bitzer semi-hermetic screw refrigeration compressor.

Screw compressors are mainly used in air compression and medium-sized refrigeration / air conditioning systems. Screw compressors can be divided into screw air compressors, screw refrigeration compressors and process gas screw compressors.

Due to the continuous improvement of the working reliability of the screw refrigeration compressor, it has gradually replaced the reciprocating compressor in the medium refrigeration capacity range, and occupied part of the centrifugal compressor market.

This article mainly introduces the composition, working principle, types and advantages and disadvantages of screw refrigeration compressors.

1. Components of Screw Refrigeration Compressor

A screw refrigeration compressor refers to a refrigeration compressor that uses one or two rotors (screws) with spiral grooves to rotate in the cylinder to compress the gas. According to the number of screw rotors, there are two types: twin-screw and single-screw.

The screw refrigeration compressor is mainly composed of a rotor, a casing (including the cylinder block in the middle and the suction and discharge end seats at both ends), bearings, shaft seals, balance pistons and gas delivery adjustment devices.

The figure below is an outline drawing of a typical open screw compressor, including a pair of rotors, cylinders and end seats at both ends.

Figure 2: The structure of an open screw compressor.

1—Suction end seat 2—Female rotor 3—Cylinder 4—Slide valve 5—Exhaust end seat 6—Male rotor

2. How Does a Screw Compressor Work

The following takes the twin-screw compressor as an example to introduce its working principle.

2.1 Suction Process

When the rotor rotates, the screw groove volume gradually expands with the rotation of the rotor and is connected with the suction port. The gas from the evaporation system enters the screw groove volume through the orifice to perform the gas suction process. After the rotor rotates to a certain angle, the suction process ends when the volume between the teeth crosses the position of the suction orifice and is disconnected from the suction orifice.

Figure 3: Working process diagram of screw refrigeration compressor.

2.2 Compression Process

When the rotor continues to rotate, the gas in the tooth slots sealed by the body, the suction end seat and the exhaust end seat is pressed to the exhaust end due to the mutual meshing of the female and male rotors, its pressure gradually increases, and the compression process begins.

2.3 Exhaust Process

When the rotor rotates so that the space between the tooth slots is connected with the exhaust hole on the exhaust end seat, the gas is pressed out and discharged from the exhaust flange port to complete the exhaust process.

Since the above three processes occur in the working cycle of each screw groove space, when the compressor is running at high speed, the working volumes of several pairs of screw groove spaces repeat the cycle of suction, compression and exhaust to make the gas delivery of the compressor continuous and smooth.

3. Types of Screw Refrigeration Compressors

Screw refrigeration compressors are all lubricated by oil injection. According to the different connection methods between the compressor and the electric motor, they are divided into three types: open type, semi-hermetic type and hermetic type.

Open type: The compressor is connected with the motor through a coupling, and it is required to install a reliable shaft seal on the extended shaft of the compressor to prevent leakage of refrigerant and lubricating oil.

Figure 4: Cutaway view of open type twin screw compressor.

Semi-hermetic type: the motor and the compressor are integrated, and connected by flanges in the middle, which can effectively prevent the leakage of refrigerant and lubricating oil. It uses refrigerant to cool the motor, eliminating the noise of the motor cooling fan in the open screw compressor unit.

Hermetic type: the motor and compressor are sealed in a container, which completely eliminates the leakage of refrigerant and lubricating oil, and the noise is the lowest. The cooling capacity range of this refrigeration compressor has exceeded 3500KW under standard working conditions (evaporating temperature: -15°C, condensing temperature: 30°C).

4. Pros and Cons of Screw Refrigeration Compressors

As far as the principle of compressing gas is concerned, the screw refrigeration compressor is the same as the reciprocating piston refrigeration compressor, and belongs to the positive displacement compressors.

In terms of its movement form, the rotor of the screw refrigeration compressor is the same as the rotor of the centrifugal refrigeration compressor, which rotates at a high speed. Therefore, the screw refrigeration compressor has the characteristics of both.

4.1 Advantages

(1) High speed, light weight, small size, and small footprint.

(2) The dynamic balance performance is good, so the foundation can be small.

(3) It features simple and compact structure, less wearing parts, easy maintenance, reliable use, and is conducive to the realization of automatic operation.

(4) It is not sensitive to liquid hammer, and the single-stage pressure ratio is high.

(5) The delivery volume is hardly affected by the exhaust pressure. In a wide range of working conditions, high efficiency can still be maintained.

4.2 Disadvantages

(1) The cost is high, and special equipment and tools are required to process the rotor.

Since the tooth surface of the rotor of the screw compressor is spirally curved in space, special tools need to be used to process it on expensive special equipment. In addition, there are high requirements for the machining accuracy of the screw compressor cylinder.

(2) Cannot be used in ultra-high pressure occasions.

Due to the limitation of rotor stiffness and bearing life, the screw compressor is only suitable for low, medium and high pressure ranges, and the exhaust pressure generally does not exceed 10MPa, and the ultra-high pressure application is still dominated by reciprocating compressors.

(3) Loud noise.

(4) Auxiliary equipment is huge.

5. Application of Refrigeration Screw Compressor

5.1 Open Screw Compressor

Figure 5: The open screw compressor unit.

Open screw refrigeration compressors are generally sold as compressor units. Manufactures usually assemble compressors, drive motors, lubrication systems, control devices for adjusting flow, safety protection devices, and monitoring instruments into one unit, which are called screw refrigeration compressor units.

Screw refrigeration compressors are widely used in the following fields:

Widely used in low temperature tests in petroleum, chemical, pharmaceutical, textile and scientific research;

Applied to low-temperature processing, storage and transportation of food, aquatic products and commercial areas;

It is used in the air conditioning of large buildings such as factories, hospitals and public places.

Advantages of open screw refrigeration compressor:

(1) The compressor is separated from the motor, so that the compressor can be used in a wider range.

(2) The same compressor can adapt to different refrigerants. In addition to using halogenated hydrocarbon refrigerants, ammonia can also be used as refrigerants by changing the materials of some parts.

(3) Motors with different capacities can be equipped according to different refrigerants and operating conditions.

Disadvantages of open screw refrigeration compressor:

The open screw refrigeration compressor has disadvantages such as high noise, easy leakage of refrigerant, and complicated oil circuit system.

5.2 Semi-Hermetic Screw Compressor

The rated power of the semi-hermetic screw refrigeration compressor is generally 10~100kW. When using R134a working fluid (refrigerant), its condensation temperature can reach 70°C. When using R404A or R407C working fluid, the single-stage evaporation temperature can reach as low as 45°C.

Therefore, it can operate safely and reliably under high condensing pressure and exhaust temperature, especially under harsh working conditions with large pressure differences.

Figure 6: Cutaway view of Bitzer CSH series semi-hermetic screw compressor.

Characteristics of the semi-hermetic screw refrigeration compressor:

(1) Both the male and female rotors of the compressor adopt the teeth number of 6:5 or 7:5, mainly to increase the peripheral speed of the rotor and the speed difference when the male and female rotors rotate at high speed.

(2) The oil separator and the main engine can be integrated. The oil separator of the compressor unit is set in the compressor body, making the unit compact.

(3) The built-in motor is cooled by refrigerant gas, and the efficiency of the motor is greatly improved. Moreover, the motor has a large overload capacity, and its size is also reduced accordingly.

5.3 Hermetic Screw Compressor

Due to the high technical requirements for manufacturing and installation, hermetic screw compressors have only been developed in recent years. The picture below is a fully enclosed screw refrigeration compressor used for water storage, refrigeration and air conditioning by Dunham-Bush Company in the United States.

Figure 7: Structure diagram of hermetic screw compressor.

The hermetic screw compressor unit is mainly suitable for independent air-conditioning or central air-conditioning systems in office buildings, transportation vehicles, libraries, commercial buildings, hospitals, residential buildings, hotels and other places that are particularly sensitive to noise. Open and semi-hermetic units are widely used in industrial and mining enterprises and civil air defense projects.

Related Info

Working Principles of Common Vacuum PumpsDifferent Types of Refrigeration Compressors and Their Applications, Brands

Classification and Application of Vacuum Pump

The Operation and Maintenance of Vacuum Pump

Common Faults, Reasons of Faults, and Solutions of Vacuum Pump