Why does the special air compressor for laser cutting suddenly become popular

Since the beginning of this year, as long as everyone pays a little attention, you will find that at least a dozen companies have launched special air compressors for laser cutting. Why did everyone launch such a product together? Don't worry, let's talk slowly!

Laser cutting uses a high-power density laser beam to irradiate the material to be cut, so that the material is quickly heated to the vaporization temperature, and evaporates to form holes. As the beam moves on the material, the holes continuously form a narrow width (such as about 0.1mm). Seam to complete the cutting of the material.

Laser cutting is widely used in sheet metal processing, metal processing, advertising production, kitchenware, automobiles, lamps, saw blades, elevators, metal crafts, textile machinery, food machinery, glasses production, aerospace, medical equipment, instrumentation and other industries. Especially in the sheet metal processing industry, it has replaced traditional processing methods and is favored by industry users. Laser cutting accounts for more than 40% of industrial laser processing and is the most important application technology in the laser processing industry.

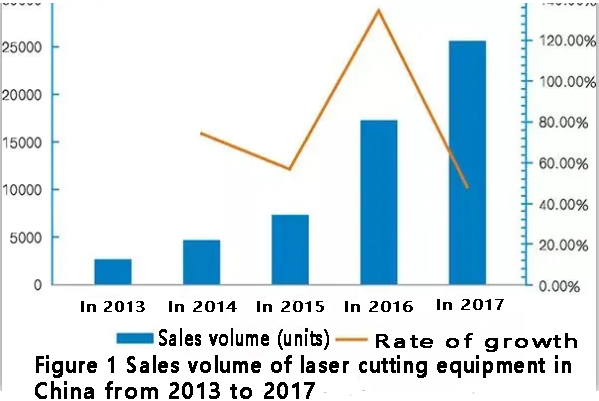

Before 2010, due to the high price of laser cutting equipment, a large-format laser cutting machine (equipped with a 4 kW laser) sold for nearly RMB 6 million. There were not many domestic companies using large-format laser cutting machines. Since 2011, domestic laser companies have vigorously developed high-power fiber laser cutting machines. Due to the unique processing advantages of high-power fiber laser processing, processing costs have dropped significantly. At the same time, combined with a variety of flexible payment methods, more and more sheet metal Processing companies, kitchen and bathroom manufacturing companies, and auto parts processing companies use laser cutting machines. In recent years, laser processing equipment has been rapidly popularized. In 2017, the sales volume of laser cutting equipment in my country exceeded 25,000 units. (see picture 1)

In 2013, my country owned approximately 50-60 laser cutting equipment companies, while fewer than 20 were capable of producing high-power products above 2000 watts. By the beginning of 2018, it is conservatively estimated that my country has more than 400 laser cutting equipment companies and more than 200 companies capable of producing high-power products of more than 3,000 watts.

In the past ten years, the laser cutting industry has undergone a series of changes, including the improvement of the quality and thickness of cutting materials, the improvement of machine power and efficiency, so that today's laser cutting machines can achieve higher speed, accuracy and better performance. Quality Efficient processing of countless parts and components, including automobiles, aerospace, medical care, plastics, electrical and electronic, textiles, woodworking, etc.

In 2012, the popular competition for fiber laser cutting equipment was 2000 watts, and in 2014 it was 3000-4000 watts. Many people think that 4 kilowatts can already meet the needs of cutting most thick plates. However, in the second half of 2016, Han's Laser first launched an 8-kilowatt machine, triggering a new round of competition for high-power laser cutting. Today, major laser cutting manufacturers are already competing for products with 12,000 watts and 15,000 watts of power. I have to admit that the upgrading of laser products is very rapid, and the market development is also changing rapidly.

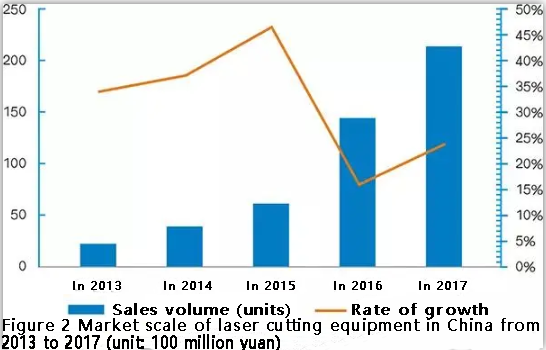

The global laser processing equipment market in 2017 was US$31.37 billion, a year-on-year increase of 12%. In 2017, the total sales scale of China's laser equipment market exceeded 44.2 billion yuan, and laser cutting equipment accounted for 46% of the national industrial laser processing equipment market. Among them, the market sales scale of small and medium power laser cutting equipment has maintained a high growth rate, and its core laser has achieved a high rate of localization. (See Figure 2)

While the laser cutting equipment market is growing rapidly, the air compressors that provide auxiliary air sources for laser cutting machines have also attracted attention from all walks of life.

Laser cutting machine can meet the cutting requirements of various materials and complex shapes. In addition to the laser that can provide high energy, auxiliary gas is an indispensable substance to complete the cutting. The auxiliary gases used for laser cutting mainly include oxygen (O2), nitrogen (N2) and compressed air (Compressed Air). Its main function is to cool the material to prevent the material from hardening, that is, to be heat treated; the second is to blow off the molten metal slag from the cutting and prevent dust from clogging the laser nozzle, protect and extend its service life.

Since the cost of nitrogen and oxygen is higher than that of compressed air, and the prices of nitrogen and oxygen are increasing year by year, using air as a cutting auxiliary gas can greatly reduce production costs by about half. In addition, since air itself contains about 20% oxygen, it can make up for the lack of oxygen and nitrogen to a certain extent. Using compressed air instead of nitrogen for cutting is very economical and practical. The cost of gas saved in one year is enough to buy 3 high-quality laser-specific integrated air compressors. Therefore, it is more and more common to use compressed air as an auxiliary gas for cutting, which has also led to the rise of the laser cutting special air compressor market.

The selection of the size of the auxiliary gas air compressor for the matching laser cutting machine should be determined mainly according to the design of the auxiliary gas pressure and nozzle size of the laser cutting head used by the laser cutting machine, so that the best air compressor and Matching of laser cutting machine.

At present, laser cutting machines that require compressed air above 1.6 MPa mainly use piston compressors, but due to the restriction of the reliability and quality of piston compressors, the development is relatively slow. Piston-type air compressors are relatively easy to obtain high pressures, but piston-type air compressors are noisy, have many wearing parts, and the exhaust oil is not handled well. Therefore, it is not recommended to use piston air compressors below 1.6MPa. It is generally recommended to use screw air compressors below 1.6MPa, and then select appropriate refrigeration dryers and precision filters. The compressor should use a permanent magnet variable frequency motor, which can maintain the stability of the air supply pressure and ensure the best cutting effect.

With the development of laser cutting machine power from low power to medium power to high power and even super power, the pressure requirement of the air compressor for the laser cutting machine has also increased from 8bar at the beginning to 13bar two years ago, and then increased to the present It’s 16bar, and it is still further developing to 20~30bar. Therefore, it is necessary to develop a small flow high pressure screw air compressor with a rated discharge pressure ≧2.0MPa.

The quality of compressed air has a very direct impact on the quality of metal laser cutting. The size and stability of the gas pressure will affect the cutting effect. Laser cutting machine users are generally equipped with a four-stage filter or even a five-stage filter, the purpose is to better protect the service life of the laser cutting machine. If the water mist and oil contained in the compressed air are not cleaned and sprayed on the protective mirror surface of the laser cutting head under high pressure, the transmission of the laser beam will be seriously affected, the focus will be scattered, the product will not be cut through, and waste will be generated. If it is an ultra-high-power laser cutting machine, as long as the protective mirror or nozzle surface sticks a little very fine oil film or water mist, it may also cause the high-energy laser to burn out the laser head.

Since most users do not have the knowledge of air compressors and compressed air purification processing, if the users purchase air compressors, air storage tanks, refrigeration dryers and filters one by one and install them by themselves, it is not only troublesome, but also the entire system. Can not meet the required compressed air quality requirements. Therefore, in the current market, a more popular approach is to integrate compressors, air storage tanks, water separators, refrigeration dryers, and filters, and provide integrated air compressor solutions for laser cutting, eliminating the need for users to configure gas storage. Tanks, cold dryers, and filters, user site installation and takeover, require multiple suppliers to provide services and other troubles, this is an ideal choice.