News

04/18/2024

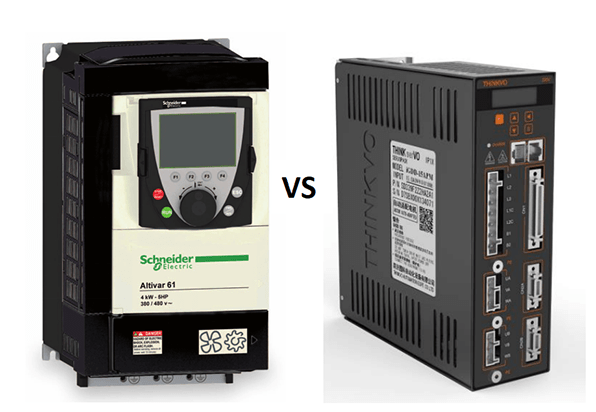

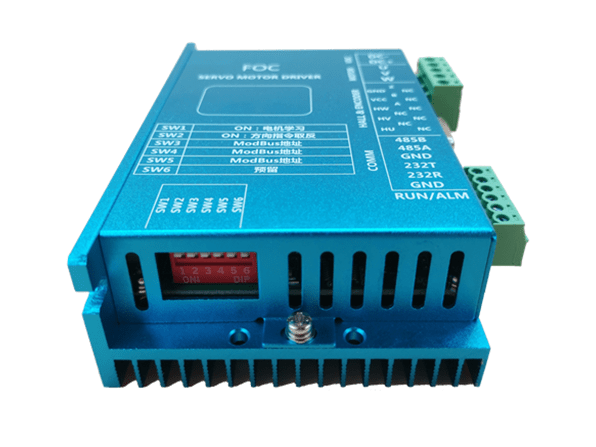

Servo Drives Basics

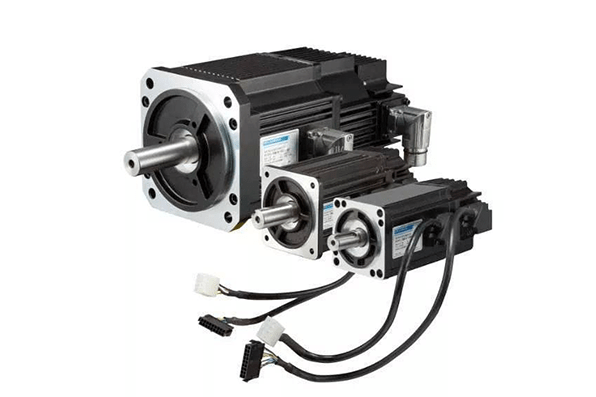

In the realm of industrial automation, the term "servo drive" has become synonymous with precision and efficiency. These sophisticated electronic devices play a crucial role in controlling the motion of motors, providing unparalleled accuracy in a variety of applications.

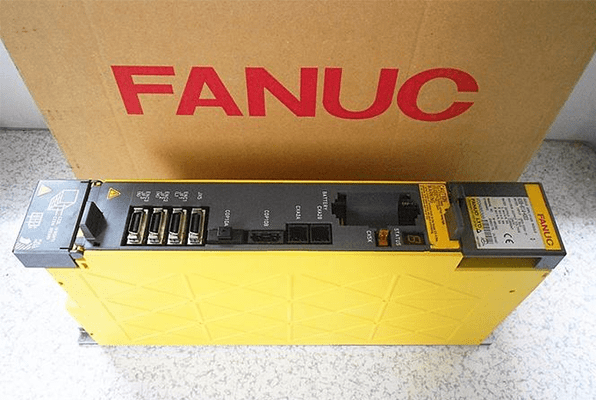

04/17/2024

Mitsubishi Servo Drive Fault Codes and Troubleshooting Methods

Mitsubishi servo system consists of servo motor, controller, and servo drive (also called servo amplifier), mainly including MR-J2S series, MR-J series, MR-H series, MR-C series, MR-J2 series, MR-J2S series, MR-E series, MR-J3 series, MR-ES series, MR-JE series, MR-J4 series, etc.

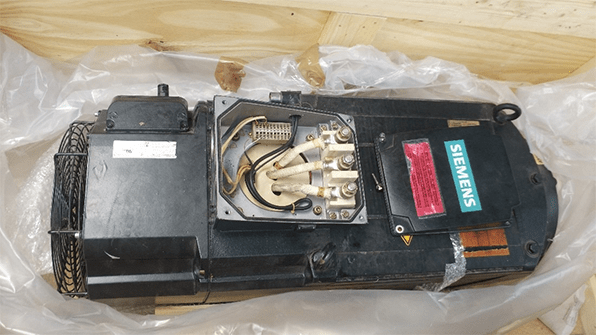

04/16/2024

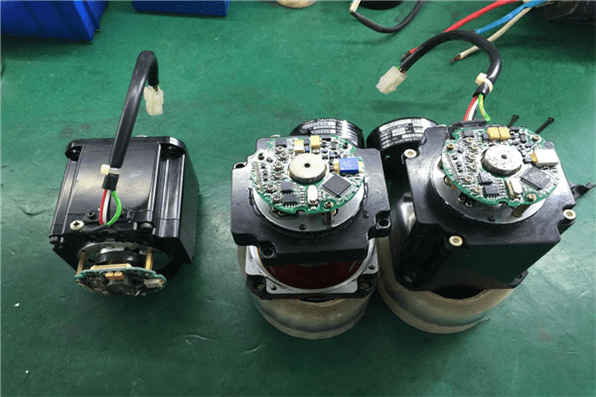

Why Do Servo Motors Fail? 9 Parts that May Malfunction with Pictures

Keeping servo motors running in optimal condition is crucial for any industrial business, especially for industries such as robotics or CNC machine tools, as the cost of downtime caused by servo motor failure can be very expensive, both financially and in terms of time.