9. Why does we need to wait at least 3 minutes after shutting down the compressor before restarting it?

When the refrigeration compressor starts, a little refrigeration oil will enter the air conditioning system with the refrigerant circulation. If there is not enough running time, the refrigeration oil will not be able to return to the compressor chamber in time. Shortly frequent shutdown after starting will cause the oil level inside the compressor to be low, which is easy to cause poor lubrication of the mechanical moving parts of the compressor.

In addition, the downtime of more than 3 minutes is mainly to give the system enough pressure balance time. Otherwise the compressor will not start normally due to the existence of high and low pressures.

10. Why can't the compressor operate under "vacuum conditions"?

The so-called "vacuum conditions" are not absolute vacuum conditions, but extremely low pressure conditions in the compressor chamber. Gas molecules will ionize under extremely low pressure.

According to actual experimental results, the compressor terminal has the lowest breakdown voltage when the internal pressure of the compressor is around 3.5 mmHg. At this time, it is easy to break down and deposit carbon inside when the compressor is powered on, which will damage the insulation of the sealed terminal. In severe cases, the sealed terminal of the compressor may burn out and drop off during operation. Therefore, it should be avoided to power on the compressor when evacuating it.

11. Is it allowed to tilt the compressor during operation?

The tilt angle of the compressor during operation should not exceed 5°.

12. Is the moisture content control of the HFC (R410A) air conditioning system stricter than that of HCFC (R22)?

Yes. POE oil used in the HFC system is decomposable by water. If the water content in the HFC system exceeds the specification value, it will cause the lubricant to decompose, the lubrication performance will deteriorate, and the reliability and service life of the compressor will decrease.

13. Can the compressor using HCFC (R22) be used after its refrigerant changed with HFC (R410A) refrigerant and HFC lubricant?

It cannot be used. If the HCFC refrigerant is directly replaced with HFC refrigerant and HFC lubricant, several situations may occur:

● Low air conditioning performance and high power consumption;

● Shortened compressor life, even compressor stalling and motor burning in a short time;

● Accidents such as compressor deformation and even explosion.

14. How to confirm whether the oil return of the compressor is normal?

It can be confirmed by observing the oil level. The compressor used in the air conditioning system is a specially made compressor with a sight glass, which is mainly used to observe the oil level height in the compressor body. Since the various mechanical moving parts of the compressor are lubricated through the crankshaft pumping oil, if the oil level is lower than a certain position, the refrigeration oil cannot be pumped to the required position.

15. Why is there a requirement for the temperature at the bottom of the compressor body during air conditioning operation?

Because if the temperature is too high, the viscosity of the compressor refrigeration oil will decrease, resulting in poor lubrication of the compressor friction pair, and in severe cases, abnormal wear of the compressor parts.

16. Under what circumstances does the compressor reverse rotation occur? What will be the result?

After the phase sequence is wrong, the three-phase compressor will produce a reverse rotation phenomenon. Since the internal oil circuit design of the compressor is determined according to the rotation direction of the compressor, if reverse rotation occurs, the lubricating oil will not be able to reach the compressor friction pair according to the normal oil circuit, and the compressor will operate without lubrication conditions.

If the compressor is running without lubrication, it will cause the parts to wear and even cause the compressor to stall and the motor to overheat and burn. Therefore, the compressor cannot rotate in reverse.

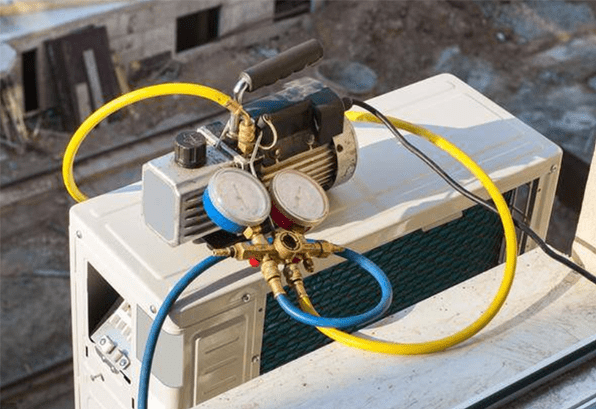

17. How to correctly charge the refrigerant in the air conditioning system?

Try not to inject directly from the suction or discharge port of the compressor. Because when the liquid refrigerant directly enters the compressor, it will accumulate in the compressor chamber in large amounts, causing problems such as poor insulation of the compressor and dilution of the refrigeration oil.

18. Is the requirement for the cooling capacity of 410A air conditioning compressor the same as that of R22 air conditioning compressor?

Due to the different refrigerant characteristics (low temperature heat storage, etc.) and the difference between the compressor test conditions and the actual operating conditions of the air conditioning system, the R410A air conditioning system has lower requirements for the compressor cooling capacity.

19. Why must the temperature in the system be above -35°C during the stable operation of the compressor?

Because the lubricating oil used by the compressor will form solid precipitation--the wax under the condition of -35°C, thus affecting the lubrication effect of the mechanical moving parts of the compressor.

20. What kind of refrigerant does R410A belong to? What are its characteristics?

R410A is a near-azeotropic refrigerant, with a theoretical COP of about 93% of R22, a unit volume cooling capacity of about 1.44 times that of R22, a pressure of about 1.57 times that of R22, and a temperature slip of less than 0.1 degrees. Because it is a high-pressure refrigerant, the compressor and air conditioning system need to make major design changes.

21. Why is the DC inverter motor more efficient than the AC inverter motor?

The AC inverter motor uses a squirrel cage winding, and the secondary loss is caused by the current generated in the squirrel cage rotor bars when the stator rotating magnetic field and the rotor bars move relative to each other.

The DC inverter motor reduces the eddy current loss on the rotor surface, uses the magnetic resistance torque to reduce the operating current, and improves the problem of poor efficiency during low-speed operation through the concentrated winding method, so that the motor efficiency is further improved. The maximum efficiency of the DC inverter motor has reached more than 95-97%, while that of the AC inverter motor is 94~95%, with a difference of 1~2%. This difference can reach more than 5-10% at low load.